Method for catalytically synthesizing anisole by using Na-NaOH/gamma-Al2O3

A technology of anisole and phenol, which is applied in the field of synthesis of anisole, can solve the problems of large amount of methylation reagents, high investment in equipment, and high cost of raw materials, and achieve the effects of good stability, good selectivity, and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Add phenol and dimethyl carbonate into the autoclave at a molar ratio of 1:3, and add 3% of the total mass of phenol and dimethyl carbonate in Na-NaOH / γ-Al 2 o 3 , under nitrogen protection at 190 ° C airtight reaction 2h. The reaction solution was detected by a gas chromatography spectrometer, and the conversion rate of phenol reached 98.52%, and the yield rate of anisole was 96.30%.

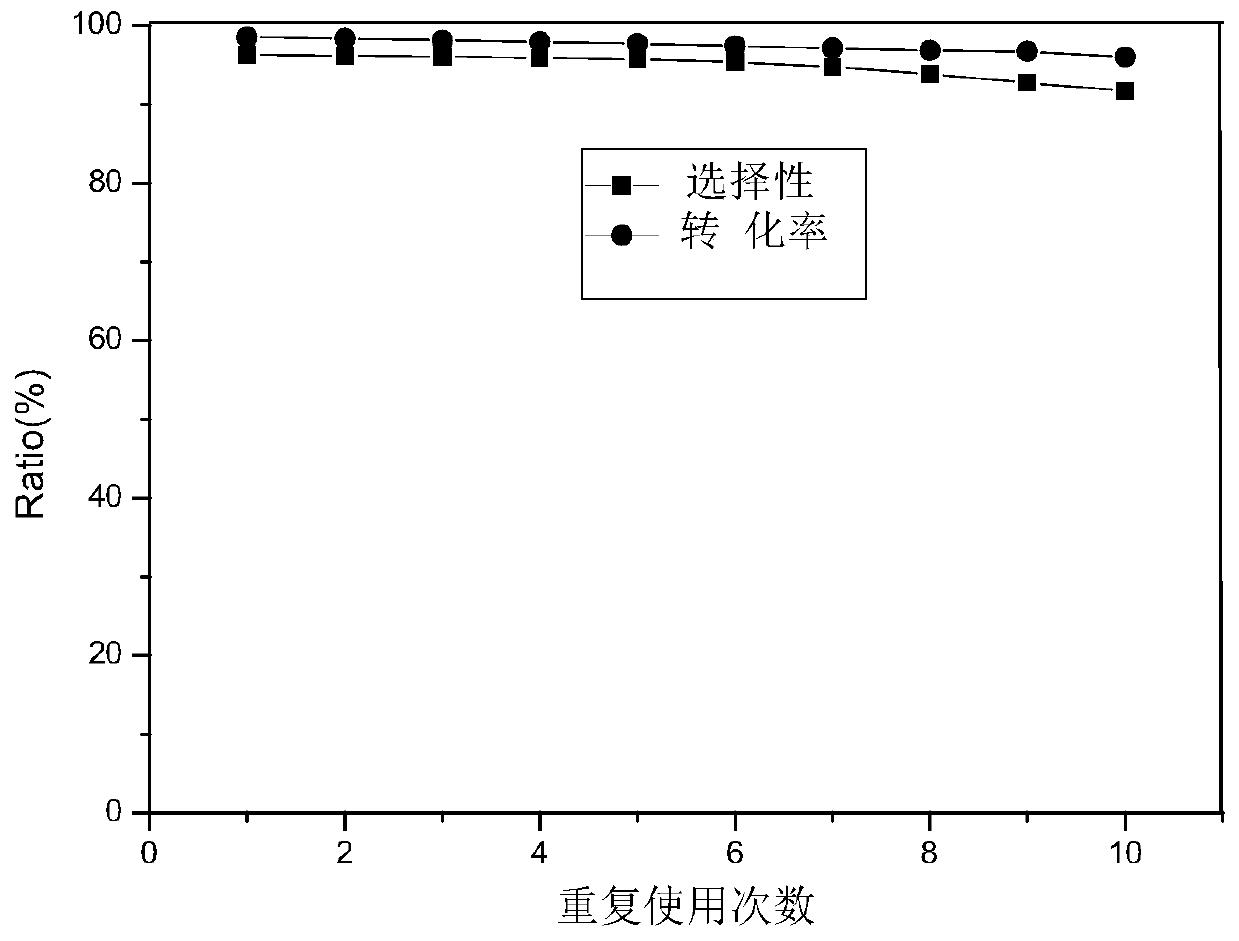

[0015] After the above reaction, directly centrifuge and recover Na-NaOH / γ-Al 2 o 3 proceed to the next reaction. See the reaction result figure 1 . Depend on figure 1 Visible, Na-NaOH / γ-Al 2 o 3 After repeated use 10 times, the conversion rate of phenol does not change substantially, and the yield of anisole does not change much at the beginning. After repeated use 6 times, it slightly decreases, but still remains above 90% overall, which shows that the catalyst of the present invention is reused. High activity and good stability.

Embodiment 2

[0017] Add phenol and dimethyl carbonate into the autoclave at a molar ratio of 1:2, and add 5% of the total mass of phenol and dimethyl carbonate in Na-NaOH / γ-Al 2 o 3 , under nitrogen protection at 180 ° C airtight reaction 3h. The reaction solution was detected by a gas chromatography spectrometer, and the conversion rate of phenol reached 81.85%, and the yield rate of anisole was 80.64%.

Embodiment 3

[0019] Add phenol and dimethyl carbonate into the autoclave at a molar ratio of 1:4, and add 5% of the total mass of phenol and dimethyl carbonate in Na-NaOH / γ-Al 2 o 3 , under nitrogen protection at 190 ° C airtight reaction 2h. The reaction solution was detected by a gas chromatography spectrometer, and the conversion rate of phenol reached 81.76%, and the yield rate of anisole was 80.75%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com