Device and method for producing methane in biological biogas fermentation tank

A biogas fermentation and production device technology, applied in the direction of stress-stimulated microbial growth, biochemical cleaning devices, biochemical equipment and methods, etc., can solve the problem of affecting the process of solid waste recycling, outdoor temperature cannot meet the fermentation requirements, Biogas fermentation can not be popularized and other problems, to achieve high-value utilization, reduce production costs and maintenance costs, reduce requirements and operational difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

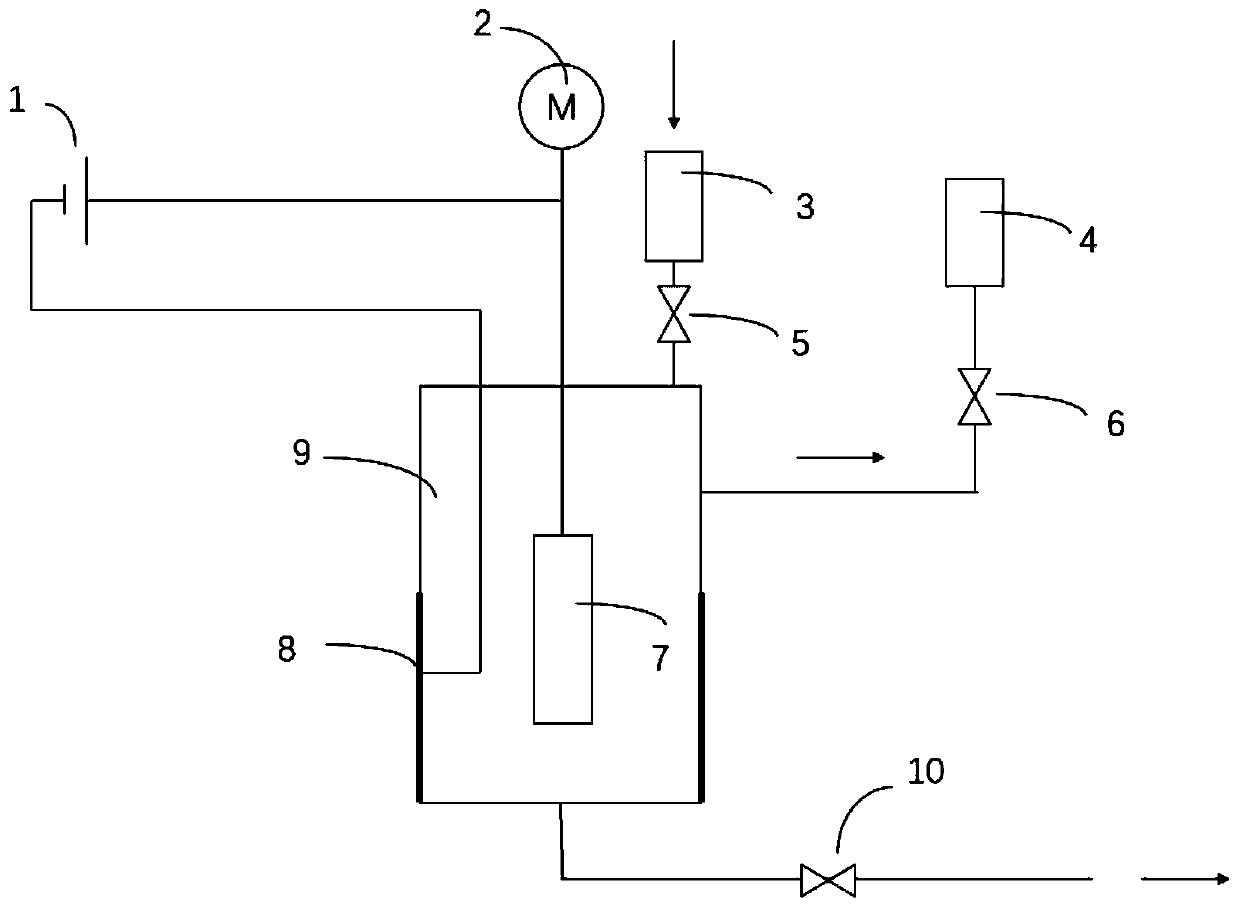

[0052] Fermentation experiments were carried out with straw powder as the substrate, the fermentation volume was selected as 1L, the liquid load factor was selected as 0.85, and the exact same methane fermentation device was selected (see figure 1 ), the DC power supply 1 is used to distinguish the closed circuit from the open circuit, the power supply voltage of the closed circuit group is selected as 1.5V, the amount of straw powder is selected as 250g, the stirring speed of the motor 2 is set at 150 rpm, stirring for 1 hour at 12:00 noon every day, and measuring The purity and total amount of methane in the produced gas and the dates when methane was produced and ceased to be produced.

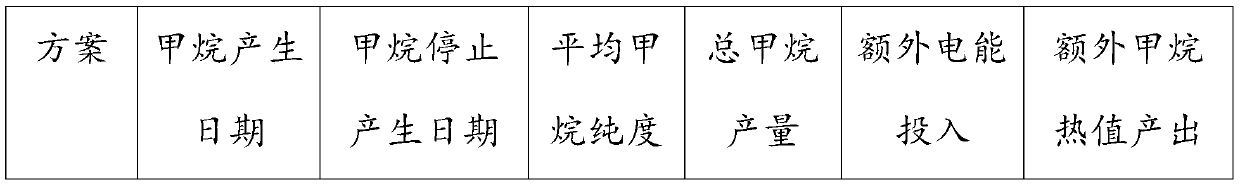

[0053] The experimental results are shown in the table below

[0054]

[0055]

[0056] Explanation: The average methane purity is the ratio of the total methane production to the total gas production. The additional electric energy input is obtained by calculating the current and vol...

Embodiment 2

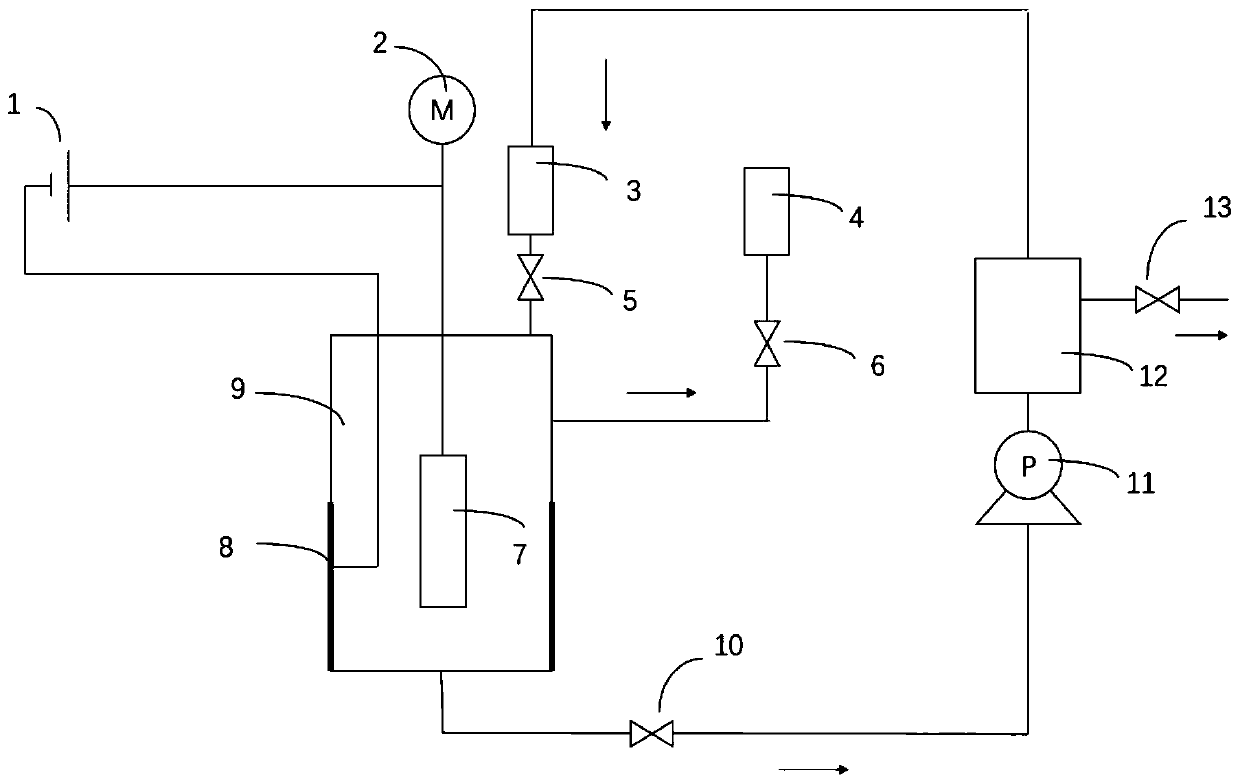

[0061] On the basis of Example 1, kitchen waste is selected as the fermentation substrate, and the operation mode is continuous feeding, such as figure 2 As shown, the feeding device 3 is connected to the discharge valve 10 with a pipeline, and a peristaltic pump 11 and a material storage device 12 are connected in series on the pipeline, and a liquid discharge valve 13 is added to the material storage device 12 to make the material storage Excess supernatant in unit 12 is drained.

[0062] On the basis of the above scheme, the continuous operation time can reach 6 months, and the utilization rate of the substrate after fermentation has also been improved. Compared with the batch fermentation of Example 1, the digestion level of the substrate has been improved by 20%. The output has also increased by about 37%. Due to the high organic matter content of kitchen waste and the high nitrogen content, it is easier to carry out fermentation. However, due to the addition of peristal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com