Multifunctional assembled photovoltaic power generation pavement and construction method thereof

A photovoltaic power generation and assembly technology, applied in the multi-functional assembly photovoltaic power generation pavement and construction field, can solve the problems of unreasonable layout of the pavement structure, complicated construction and repair process, etc., achieve excellent long-term use performance, save manpower and time, The effect of dispersing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

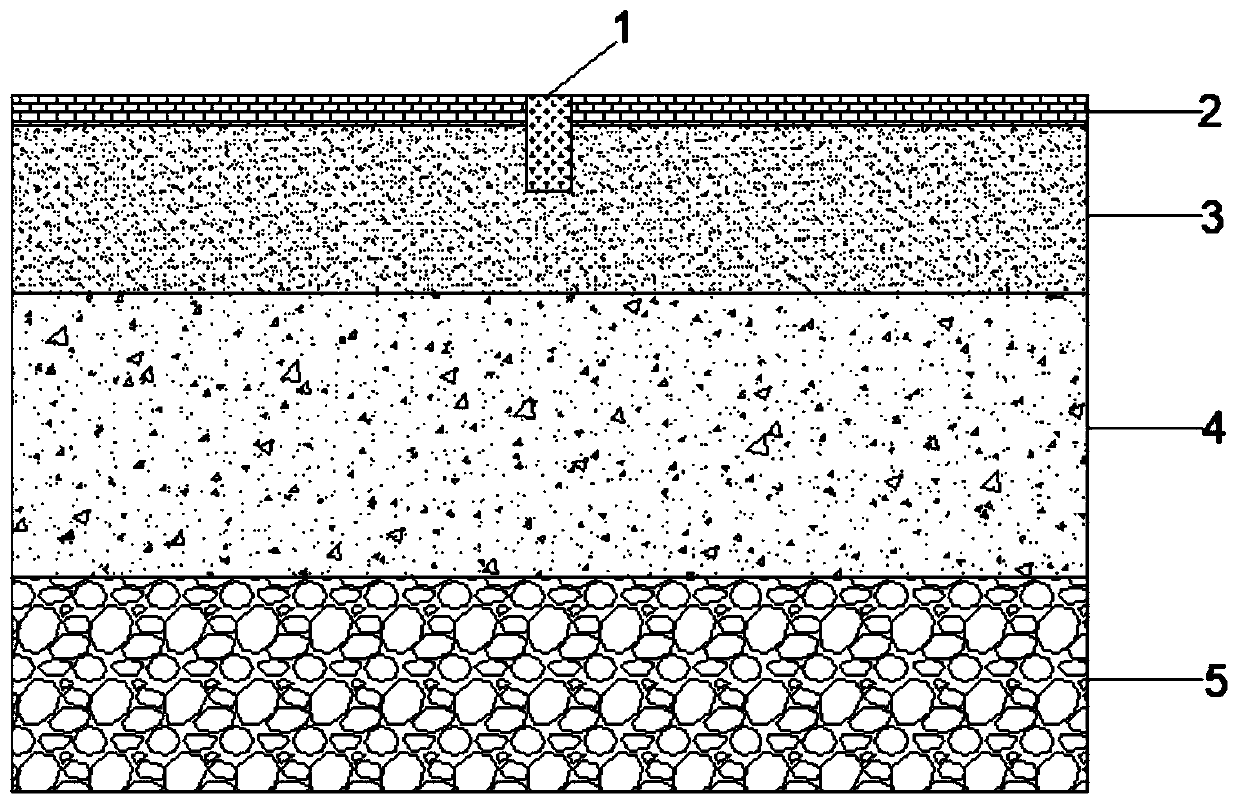

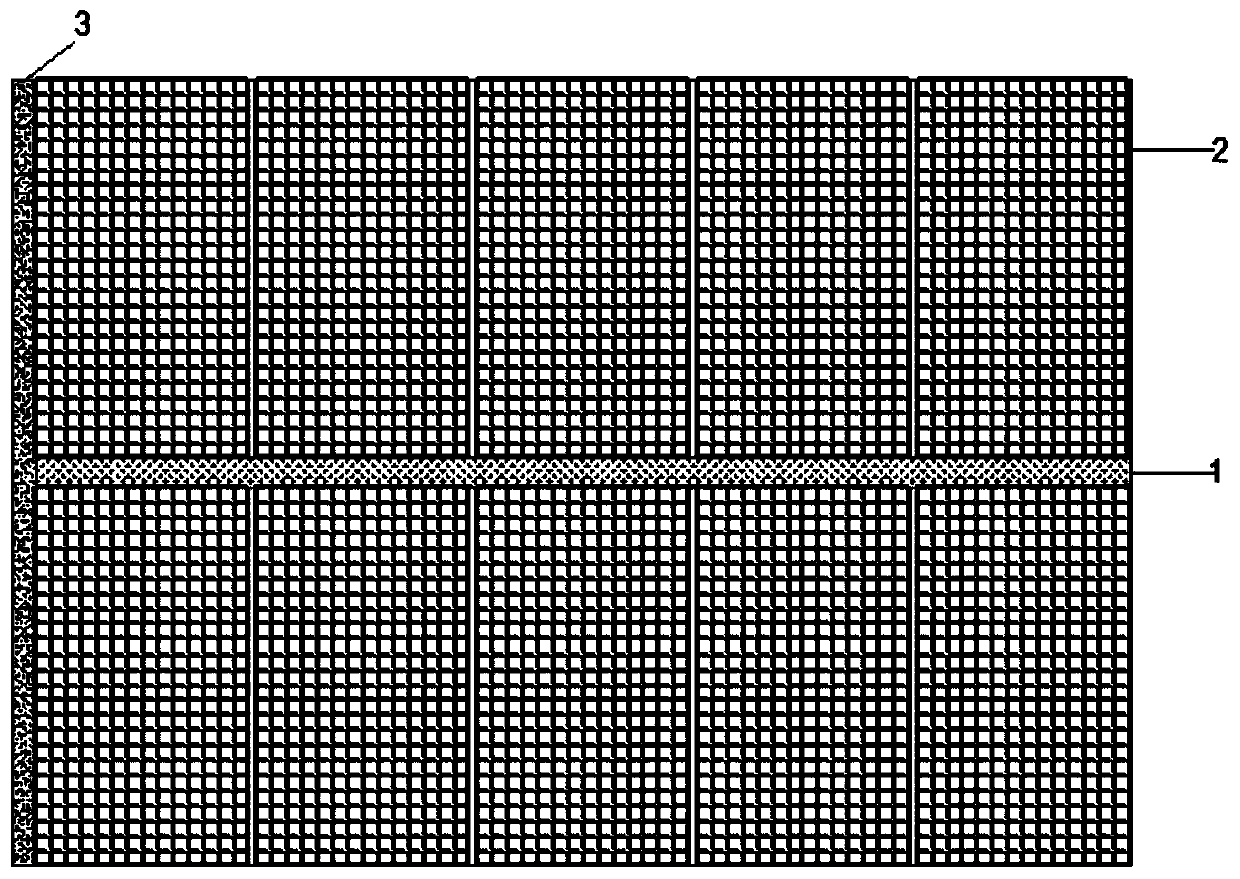

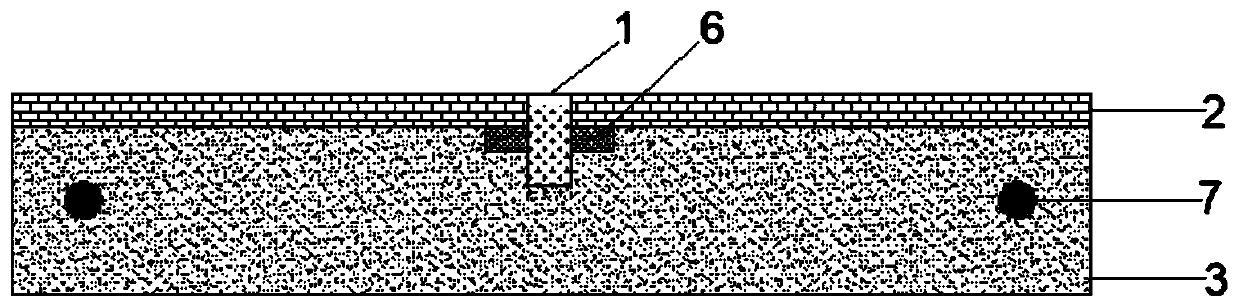

[0051] In a typical implementation of the present application, such as figure 1 As shown, the multifunctional prefabricated photovoltaic power generation surface includes at least the sequential arrangement from top to bottom: roadbed, base layer, asphalt surface layer, ECC stress layer, photovoltaic panel layer, between ECC stress layer and surface layer and solar photovoltaic power generation layer Has a very thin bondline.

[0052] The roadbed can be a soil roadbed that meets the requirements of my country's "Highway Roadbed Design" (JDGD30); its technical indicators should meet the regulations of my country's "Highway Roadbed Construction Technical Specifications" (JTJF10);

[0053] The base layer is a flexible base layer of large particle size permeable asphalt mixture (LSPM) (corresponding to the LSPM base layer in the figure). It is necessary to follow the requirements of the "Large-Size Permeable Asphalt Mixture (LSPM) Flexible Base Design and Construction Guidelines"...

Embodiment 2

[0066] Based on the above-mentioned assembled ECC photovoltaic pavement structure, this embodiment discloses a construction method, which includes the following steps:

[0067] 1 The specific steps of the prefabrication of the ECC board are as follows:

[0068] (1) Weigh a sufficient amount of cement, fly ash, quartz sand, fiber and other materials and mix them with an ECC mixer.

[0069] (2) After the materials are evenly stirred, pour the ECC into the formwork prepared in advance. In order to ensure that the size of the prefabricated ECC plate and the quality of the reserved rectangular groove and semicircular line hole are qualified, a steel test mold should be used. At the same time, during the pouring process, the ECC in the trial mold should be inserted and tamped several times to ensure that the ECC board is even and dense. After the pouring is completed, the upper surface of the test piece is carefully smoothed, and finally a steel plate is placed on the top of the te...

Embodiment 3

[0081] According to the process of embodiment 2, the photovoltaic pavement is laid, and when the pavement is damaged and needs to be repaired, the implementation steps are as follows:

[0082] If the photovoltaic panel is damaged and loses its road function, the damaged panel should be removed and replaced with a new one, and the pipeline connection should be restored to the damaged panel for subsequent repair.

[0083]If the ECC layer is damaged and needs to be replaced:

[0084] 1. The prefabrication process of the ECC board and the pasting of the photovoltaic panel are the same as in Example 1

[0085] 2. Remove the damaged ECC board, and re-level the lower asphalt concrete layer, and apply the adhesive layer evenly after leveling.

[0086] 3. Use a crane to transport the new ECC board to the site, and stick it tightly on the adhesive layer.

[0087] 4. Restore the connection between the plate pipeline and the adjacent pipeline, and perform grouting treatment on the pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com