Organic solar cell made of organic-inorganic cathode modification layer material and preparation method thereof

A cathode modification layer and solar cell technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of sensitivity to thickness changes, device performance limitations, and poor conductivity of polymer films, so as to reduce interfacial charge recombination and enhance electron transport and reduce recombination, improve interface morphology and crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

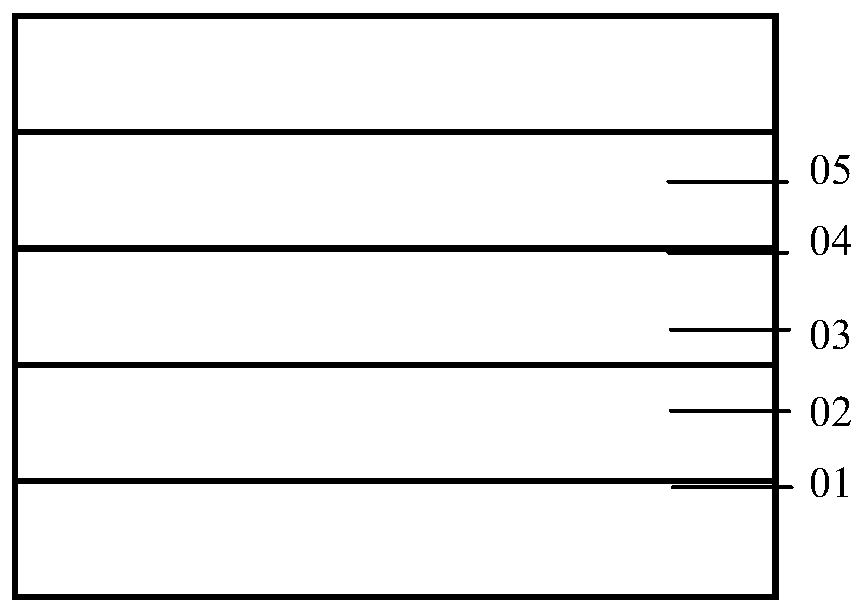

[0038] The organic solar cell device structure of the organic-inorganic cathode modification layer material in Example 1 is: ITO / Ti 3 C 2 T x -PDA:ZnO / PTB7:PCBM / MoO 3 / Ag.

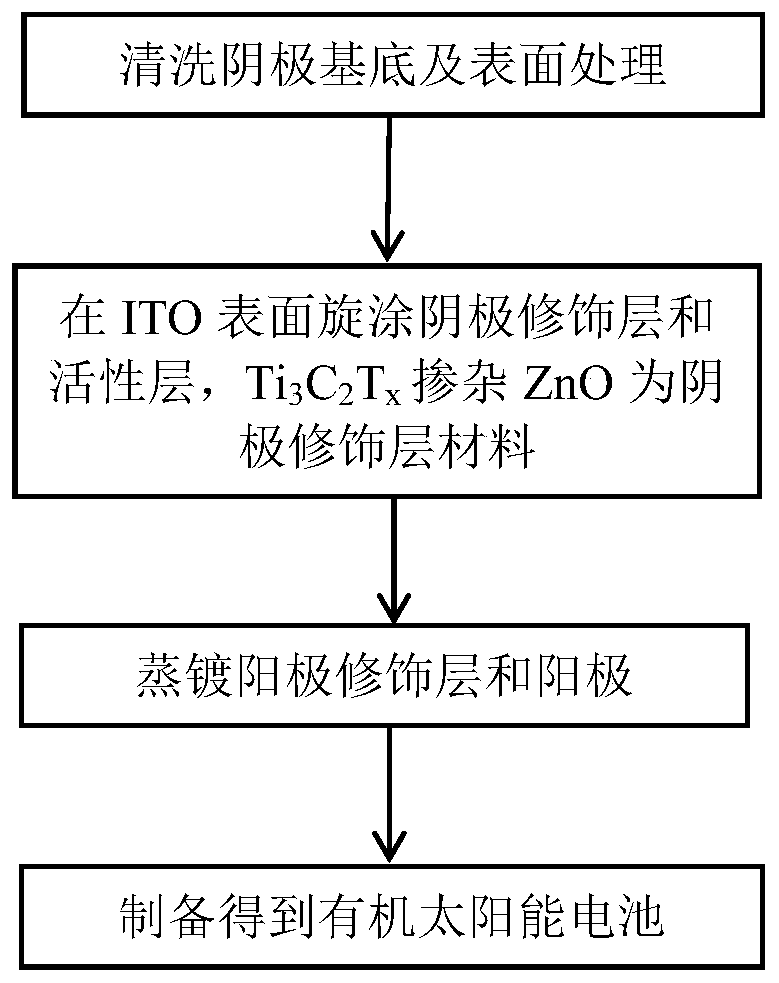

[0039] The preparation process of the above-mentioned organic solar cell is as follows:

[0040] Step 1. Ultrasonic cleaning with detergent, deionized water, acetone, absolute ethanol, and isopropanol in sequence for 25 minutes; then drying in a vacuum oven at 80°C.

[0041] Step 2, performing surface plasma treatment on the surface of the washed and dried cathode substrate (ITO) for 12 minutes.

[0042] Step 3, spin-coating a cathode modification layer on the ITO surface treated in step 2;

[0043] The cathode modification layer is made of Ti modified by PDA 3 C 2 T x Composite with ZnO, the polymerization time of dopamine is 2h. The preparation process of the cathode modification layer is as follows: firstly, dopamine is dissolved in Tris buffer solution, and the pH of the solution is adjusted t...

Embodiment 2

[0055] The organic solar cell device structure of the organic-inorganic cathode modification layer material in Example 2 is: ITO / Ti 3 C 2 T x -PDA:ZnO / PTB7:PCBM / MoO 3 / Ag.

[0056] The preparation process of the above-mentioned organic solar cell is as follows:

[0057] Step 1. Ultrasonic cleaning with detergent, deionized water, acetone, absolute ethanol, and isopropanol in sequence for 15 minutes; then drying in a vacuum oven at 60°C.

[0058] Step 2, performing surface plasma treatment on the surface of the washed and dried cathode substrate (ITO) for 12 minutes.

[0059] Step 3, spin-coating a cathode modification layer on the ITO surface treated in step 2;

[0060] The cathode modification layer is made of Ti modified by PDA 3 C 2 T x Composite with ZnO, the polymerization time of dopamine is 0.5h. The preparation process of the cathode modification layer is as follows: firstly, dopamine is dissolved in Tris buffer solution, and the pH of the solution is adjusted...

Embodiment 3

[0066] The organic solar cell device structure of the organic-inorganic cathode modification layer material in Example 3 is: ITO / Ti 3 C 2 T x -PDA:ZnO / PTB7:PCBM / MoO 3 / Ag.

[0067] The preparation process of the above-mentioned organic solar cell is as follows:

[0068] Step 1. Ultrasonic cleaning with detergent, deionized water, acetone, absolute ethanol, and isopropanol in sequence for 20 minutes; then drying in a vacuum oven at 80°C.

[0069] Step 2, performing surface plasma treatment on the surface of the washed and dried cathode substrate (ITO) for 15 minutes.

[0070] Step 3, spin-coating a cathode modification layer on the ITO surface treated in step 2;

[0071] The cathode modification layer is made of Ti modified by PDA 3 C 2 T x Composite with ZnO, the polymerization time of dopamine is 1h. The preparation process of the cathode modification layer is as follows: firstly, dopamine is dissolved in Tris buffer solution, and the pH of the solution is adjusted t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com