Lithium ion battery diaphragm, manufacturing method and application thereof

A lithium-ion battery and separator technology, applied in batteries, battery pack components, circuits, etc., can solve the problems of insufficient heat resistance of the separator and high risk of short-circuiting of lithium-ion batteries, and achieve good uniformity, reduced time, The effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

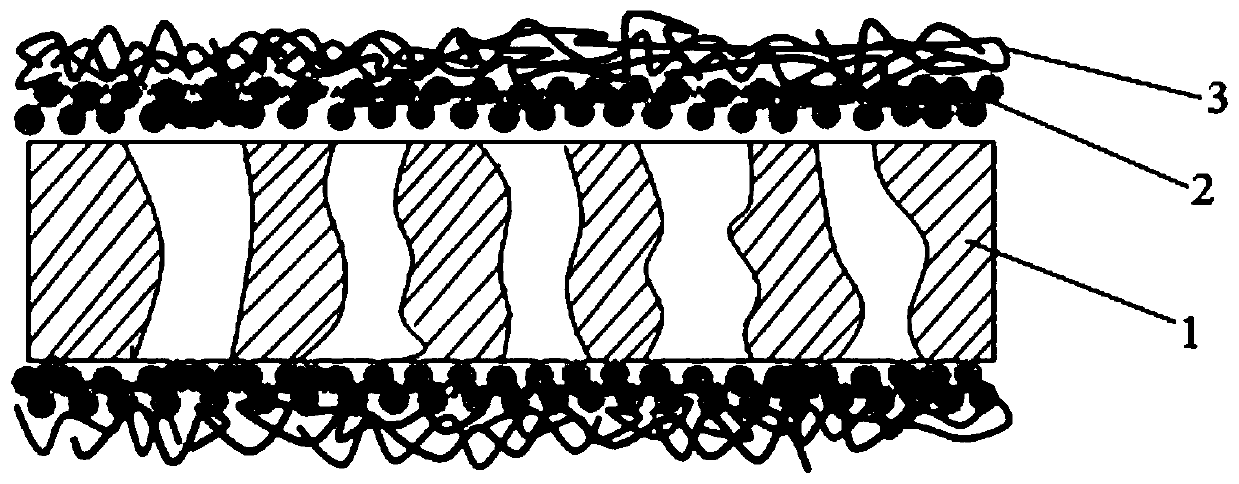

[0099] The lithium-ion battery separator described in this example is recorded as 5P+2C+PE12+2C+5P; where PE12 represents the thickness of the polyethylene substrate is 12 μm, 2C represents the thickness of the ceramic coating layer on one side is 2 μm; 5P represents the thickness of the single-side The thickness of the surface water-based polyvinylidene fluoride layer is 5 μm;

[0100] Preparation method of lithium-ion battery diaphragm:

[0101] (1) Coating slurry containing nano-ceramic materials on both sides of a polyethylene substrate with a thickness of 12 μm to obtain a polymer substrate containing a ceramic coating layer, the thickness of the ceramic coating layer on one side is 2 μm;

[0102] The mass percentage of the nano-ceramic material in the slurry containing the nano-ceramic material is 40wt.%, the mass percentage of the water-based acrylic acid is 2wt.%, and the rest is water;

[0103] Wherein, the nano-ceramic material is alumina;

[0104] (2) Immerse the ...

Embodiment 2

[0119] The lithium-ion battery separator described in this embodiment is recorded as 5P+1.5C+PE9+1.5C+5P;

[0120] The difference between this embodiment and Example 1 is that the thickness of the polyethylene substrate in step (1) is 9 μm, the thickness of the ceramic coating layer on one side of the polyethylene substrate is 1.5 μm, and other conditions are the same as in Example 1. Compared to the exact same.

Embodiment 3

[0122] The lithium-ion battery separator described in this embodiment is recorded as 2P+1.5C+PP16+1.5C+2P;

[0123] The difference between this example and Example 1 is that the polyethylene substrate with a thickness of 12 μm is replaced with a polypropylene substrate with a thickness of 16 μm, and the thickness of the ceramic coating layer on one side of the polypropylene substrate is 1.5 μm. The thickness of the water-based polyvinylidene fluoride layer on one side surface is 2 μm; other conditions are exactly the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com