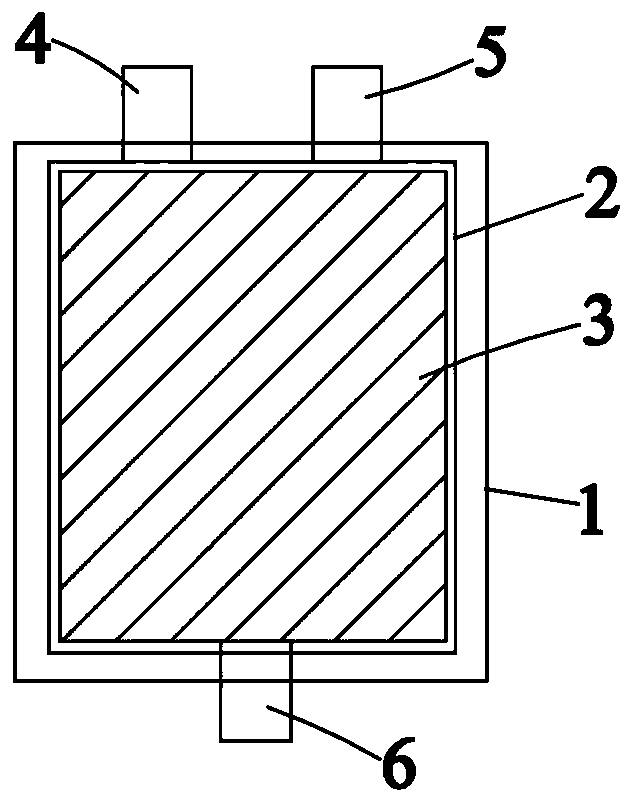

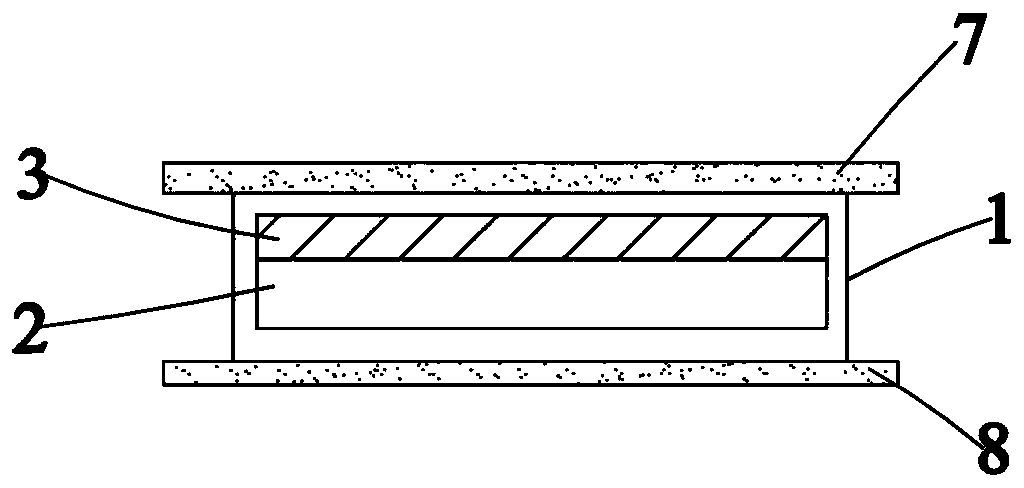

Three-electrode lithium ion battery and preparation method thereof

A lithium-ion battery and three-electrode technology, which is applied in the field of lithium-ion batteries, can solve problems such as high difficulty and easy damage to the interface structure of the battery cell, improve test accuracy and stability, avoid difficult production, and stabilize the interface for charging and discharging The effect of voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

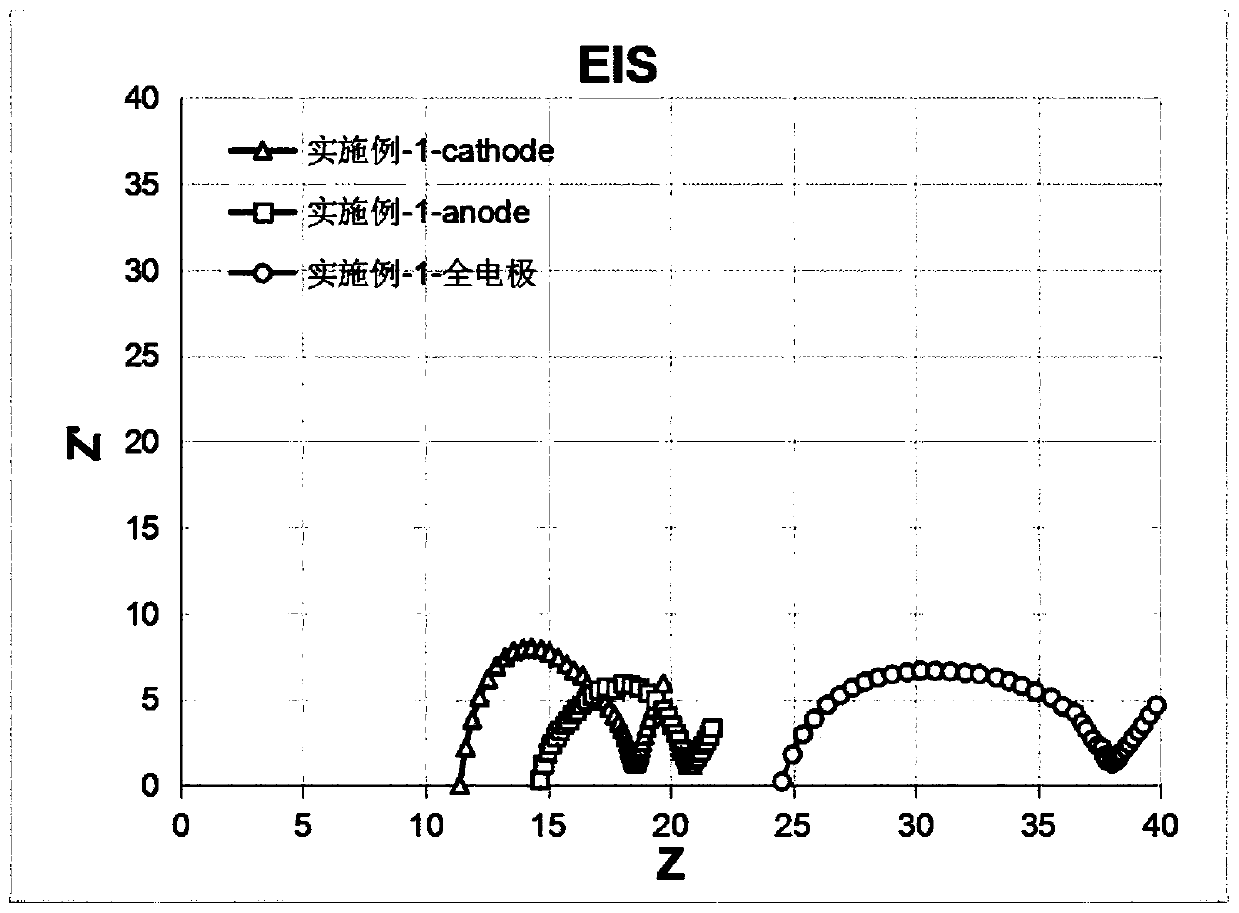

Embodiment 1

[0038] Preparation of positive electrode sheet: high-voltage 4.4V positive electrode active materials lithium cobalt oxide (purchased from Tianjin Bamo), CNTs (carbon nanotubes), conductive carbon black and PVDF (polyvinylidene fluoride) were prepared in a mass ratio of 97:0.5:1 : 1.5 Mix evenly, then disperse in N-methyl-2-pyrrolidone (NMP) to obtain a positive electrode slurry; evenly coat the positive electrode slurry on both sides of the aluminum foil, roll and cut to obtain a positive electrode sheet, and finally Ready to use after baking and vacuum drying.

[0039] Preparation of negative electrode sheet: The negative electrode material (purchased from Jiangxi Zichen), conductive carbon black, CMC (carboxymethyl cellulose) and SBR / PAA were mixed uniformly according to the mass ratio of 95:1.5:1.5:2, and then dispersed in deionized water. The negative electrode slurry is obtained in water; the negative electrode slurry is evenly coated on both sides of the copper foil, an...

Embodiment 2

[0043] The difference from Example 1 is the preparation of the reference electrode (lithium titanate pole piece):

[0044] Lithium titanate, conductive acetylene black and PVDF (polyvinylidene fluoride) are uniformly mixed in a mass ratio of 95:3:2, and then dispersed in N-methyl-2-pyrrolidone (NMP) to obtain lithium titanate slurry; The lithium titanate slurry is evenly coated on the aluminum foil to form a lithium titanate slurry layer. After rolling and slitting, the lithium titanate pole piece is obtained, and the nickel electrode lugs and the diaphragm are wrapped by transfer welding. Finally, it is baked and vacuum dried. for later use.

[0045] The rest are the same as in Embodiment 1, and are not repeated here.

Embodiment 3

[0047] The difference from Example 1 is the preparation of the reference electrode (lithium titanate pole piece):

[0048] Lithium titanate, carbon nanotubes and PVDF (polyvinylidene fluoride) are uniformly mixed in a mass ratio of 92:5:3, and then dispersed in N-methyl-2-pyrrolidone (NMP) to obtain lithium titanate slurry; The lithium titanate slurry is evenly coated on the aluminum foil to form a lithium titanate slurry layer. After rolling and slitting, the lithium titanate pole piece is obtained, and the nickel electrode lugs and the diaphragm are wrapped by transfer welding. Finally, it is baked and vacuum dried. for later use.

[0049] The rest are the same as in Embodiment 1, and are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com