Biological ball deodorization method for waste gas treatment

A waste gas treatment and bio-ball technology, which is applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of secondary pollution of filter materials, poor deodorization effect, and influence on deodorization effect, so as to improve treatment efficiency, Increased contact probability and uniform exhaust gas volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

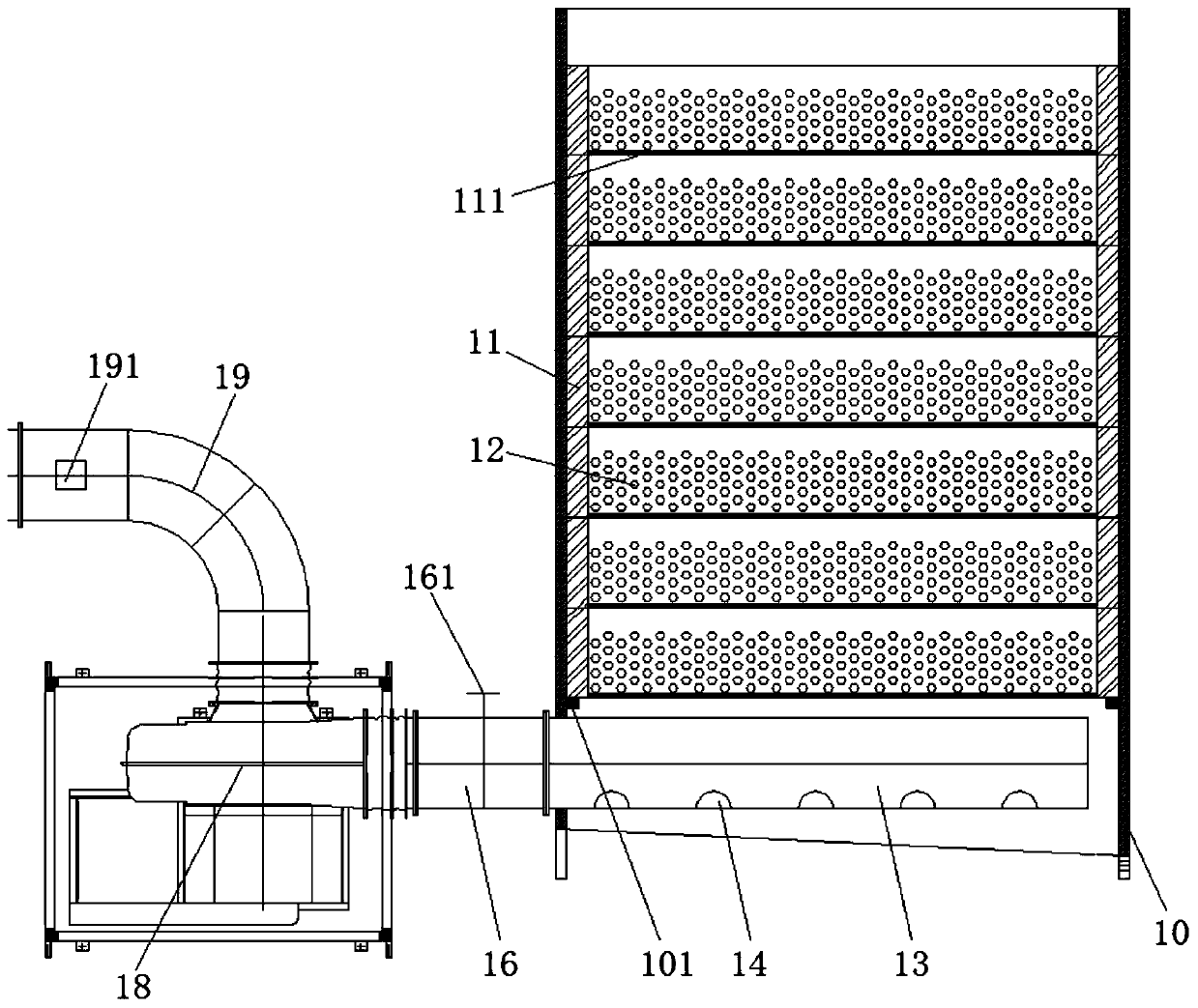

[0034] see Figure 1-2 , a biological ball deodorization method for waste gas treatment, comprising the following steps:

[0035] (1) First use the air intake fan 18 to collect and divert the waste gas of the same type to the bottom of the deodorization box 10;

[0036] (2) Multi-layer porous deodorizing bed 11 is set in deodorizing box 10, and a certain amount of bio-balls 12 are tiled in every layer of deodorizing bed 11, and a certain amount of bio-ball 12 is sprayed on the surface of bio-ball 12 simultaneously. Bacterial liquid (containing microbial liquid) used to treat the waste gas;

[0037] (3) Then make the waste gas pass through the multi-layer porous deodorizing bed 11 evenly from the bottom, so that the gas can fully contact and react with the microorganisms to achieve microbial deodorization, and the deodorized gas is discharged through the upper end of the deodorization box.

[0038] Further, the deodorizing beds 11 are sequentially stacked inside the deodorizi...

Embodiment 2

[0050] The same as embodiment 1 is not repeated, and the difference with embodiment 1 is:

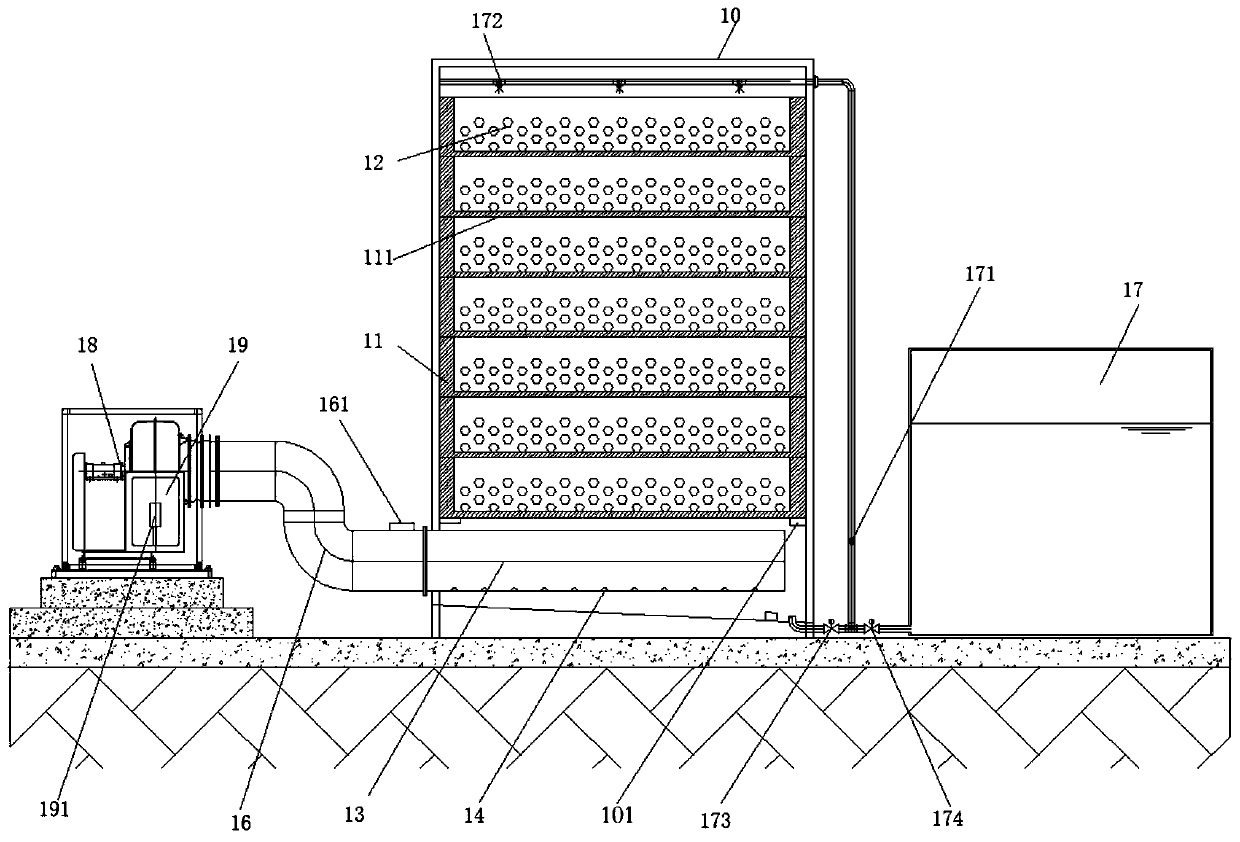

[0051] see image 3 , further, also includes a replenishing water tank 17, the replenishing water tank 17 is located at one side of the deodorizing tank 10, the replenishing water tank 17 is connected with the bottom of the deodorizing tank 10 through a pipeline, and a water replenishing tank 17 and the deodorant tank 10 are provided with Circulation pump 71, the water inlet end of the circulation pump 171 communicates with the middle part of the pipeline, and the upper end of the deodorization tank 10 is provided with evenly distributed spray pipes 172, and the spray pipes 172 communicate with the water outlet end of the circulation pump 171 through pipelines A first gate valve 173 and a second gate valve 174 are respectively provided on the pipelines at both ends of the circulation pump 171 .

[0052] The design of the circulation pump 171 and the replenishing water tank 17 can not o...

Embodiment 3

[0059] The same as embodiment 1 is not repeated, and the difference with embodiment 1 is:

[0060] see Figure 8 , a kind of method that adopts PP (polypropylene) and sawdust to prepare bioball, comprises the following steps:

[0061] (1) Process wood chips into wood chip masterbatch;

[0062] (2) Send the main material PP (polypropylene), sawdust masterbatch, foaming agent, and lubricant into the autoclave at a ratio of 0.75:0.12:0.06:0.07 for mixing and stirring to obtain material A;

[0063] (3) Feed material A into the extruder for extrusion drawing and pelletizing, with a particle size of 1-5mm;

[0064] (4) heating and pressurizing the particles in a foaming device to obtain disposable foamed particles;

[0065] (5) pre-compressing the primary foamed particles to implement secondary foaming, and drying the secondary foamed particles to obtain foamed particles;

[0066] (6) The foamed particles are sent into the extruder to melt and extrude the plate-shaped foam plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com