Chocolate coating formula

A chocolate coating and chocolate technology, applied in the direction of fat-containing food ingredients, cocoa, baking, etc., can solve the problems of inability to fully improve heat resistance, crack resistance and taste, easy to crack, and insufficient toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

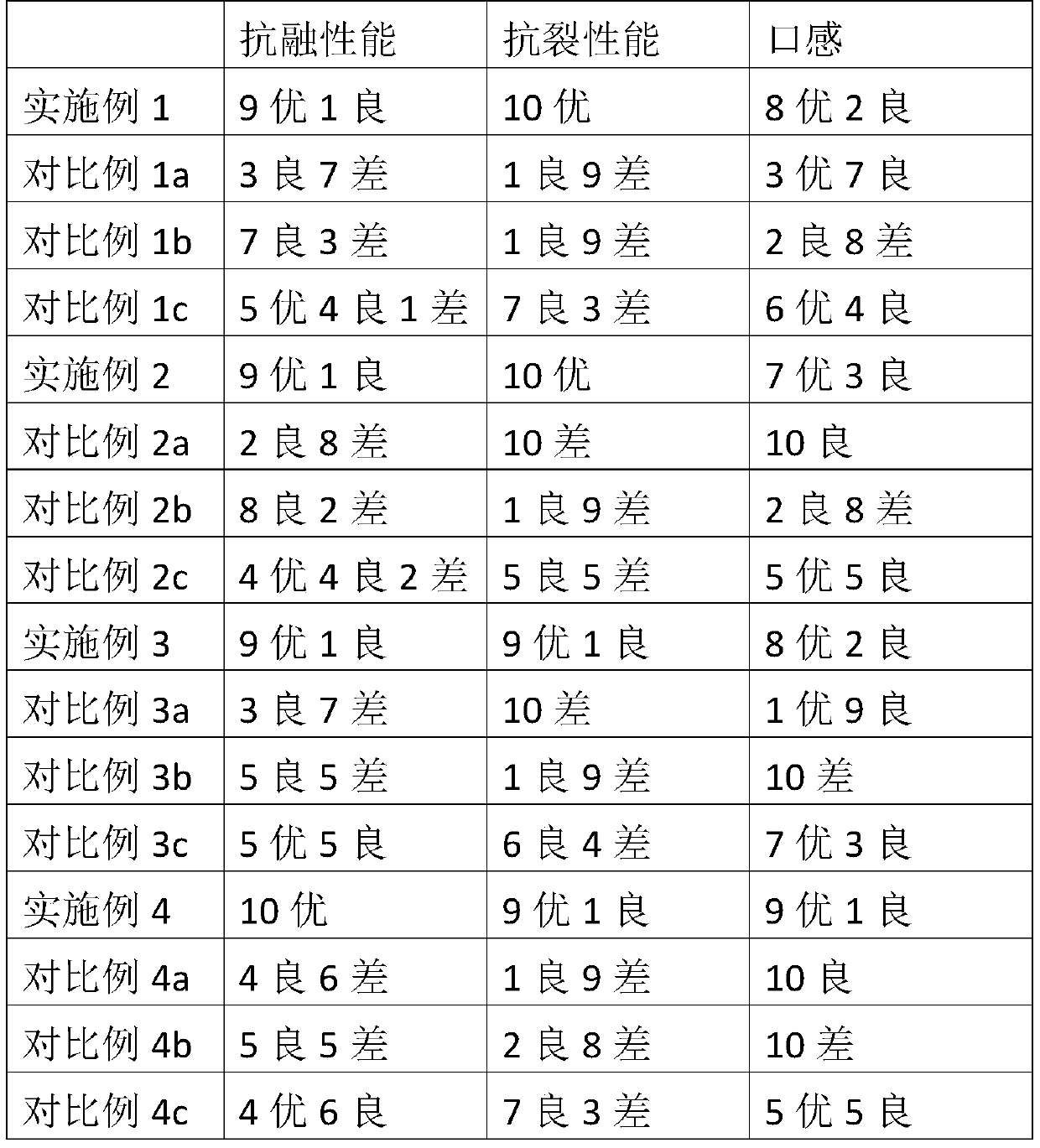

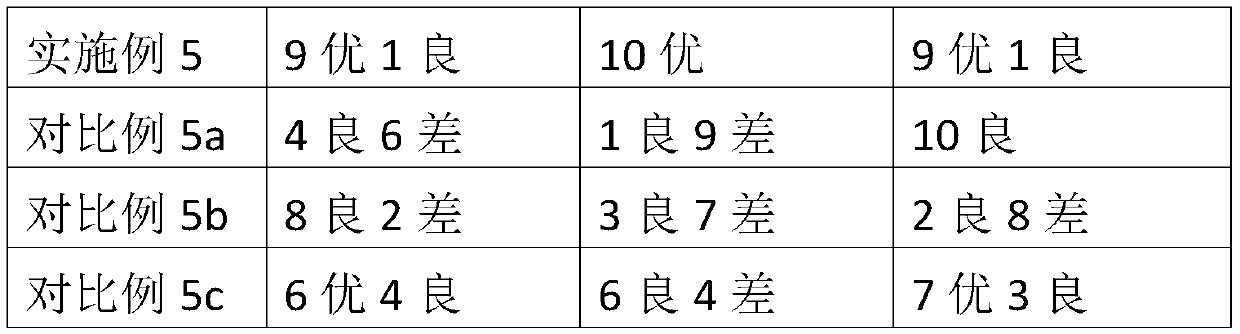

Examples

Embodiment 1-5

[0058] The formula of the chocolate coating of embodiment 1-5, formula comprises base component and added component;

[0059] Wherein, basic component (weight part) is as follows:

[0060] 38 parts cocoa butter

[0061] 34 parts white sugar

[0062] 14 parts skimmed milk powder

[0063] Phosphate starch 14 parts

[0064] The basic components of Examples 1-5 are all the same; among the above basic components, cocoa butter is purchased from Oran International Co., Ltd., and the product model is 700-SB; white sugar is white granulated sugar, purchased from Guangzhou Huatang Food Co., Ltd. First-grade white sugar; skimmed milk powder was purchased from Fonterra Group; phosphate starch was purchased from Shanghai Peihong New Material Technology Co., Ltd.

[0065] The additive component of embodiment 1-5 is pectin and compounded emulsifier;

[0066] Wherein, based on 100 parts of basic components,

[0067] The added components of Example 1 are 1.5 parts of pectin and 2 parts o...

Embodiment 6-7

[0079] The formula of the chocolate coating of embodiment 6-7, formula comprises base component and added component;

[0080] Wherein, basic component (weight part) is as follows:

[0081] 40 parts cocoa butter

[0082] 34 parts white sugar

[0083] 13 parts skimmed milk powder

[0084] Phosphate starch 13 parts

[0085] The basic components of embodiment 6-7 are all the same, and the source of basic component is the same as above-mentioned embodiment 1-5.

[0086] The additive component of embodiment 6-7 is pectin, compound emulsifier and essence;

[0087] Wherein, based on 100 parts of basic components,

[0088] The added components of embodiment 6 are 1.5 parts of pectin, 2 parts of compound emulsifier and 0.6 part of essence; wherein, the compound emulsifier is calculated by mass percentage, and its composition is: 35% polyglycerol ester, 40% polyglycerol Glyceryl Ricinoleate and 25% Span 65 (Sorbitan Tristearate).

[0089] The added components of Example 7 are 2 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com