Phosphogypsum-based self-gas-generating expansion slurry fire-preventing and fire-extinguishing material and preparation method thereof

A phosphogypsum, anti-fire technology, applied in the direction of fire prevention equipment, etc., can solve problems such as pollution and increase environmental risks, and achieve the effect of reducing pollution and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

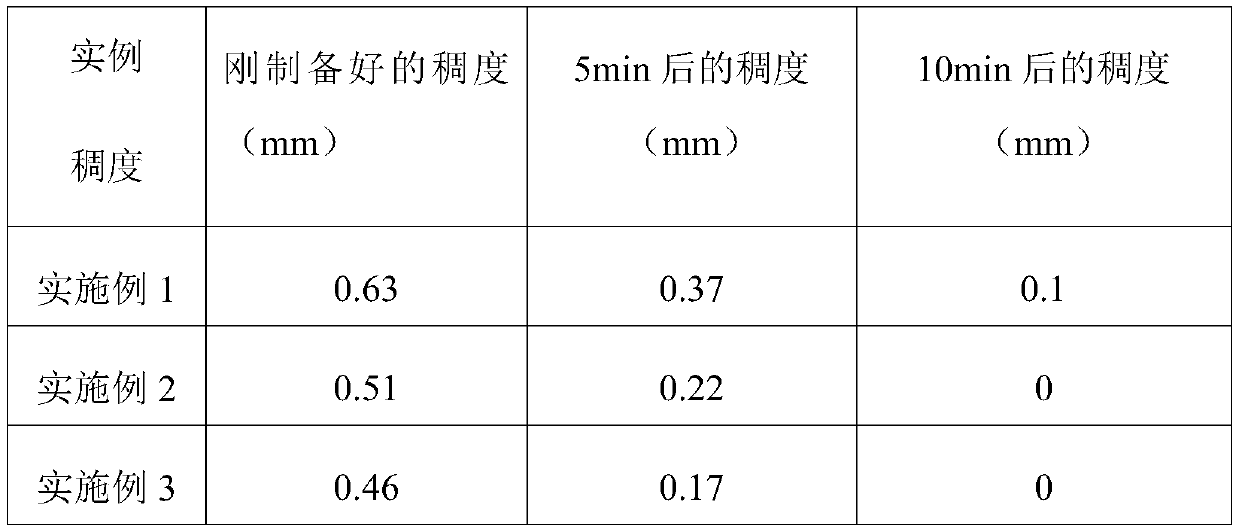

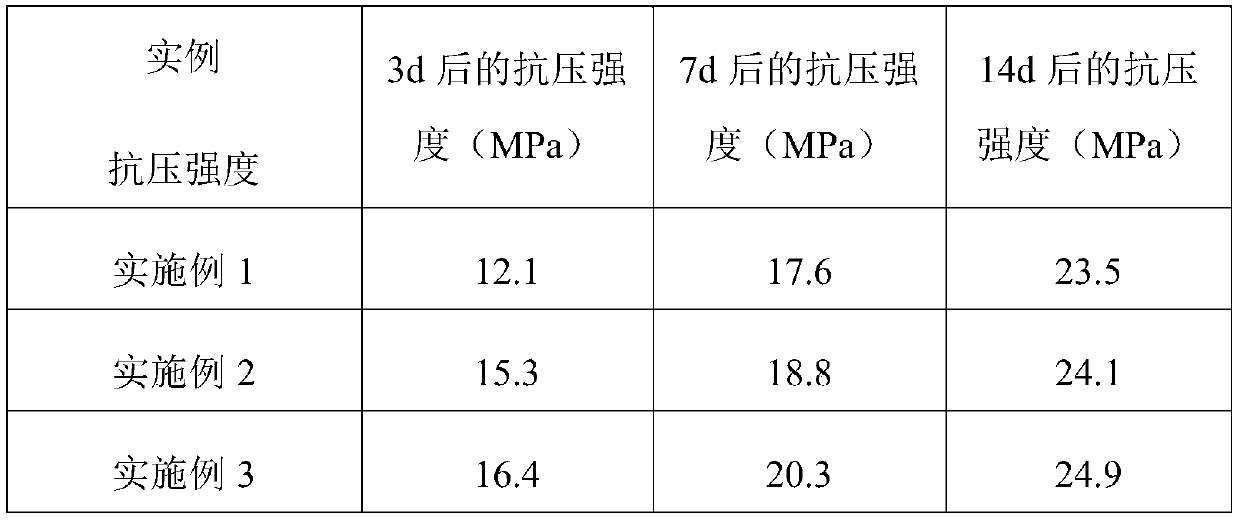

Embodiment 1

[0020] A phosphogypsum-based self-produced gas-expanding slurry fire-fighting material, consisting of the following components and parts by weight: 55 parts of phosphogypsum with a pH of 2 to 3, 30 parts of water, 9 parts of ordinary Portland cement, and poly 0.18 parts of oxyethylene alkylamine, 0.9 parts of hydroxyethyl cellulose, 0.22 parts of acrylic acid, 0.39 parts of sodium methacrylate sulfonate, 0.01 parts of ammonium persulfate, 4.0 parts of sodium bicarbonate, 0.3 parts of micro silicon powder.

[0021] The specific steps of the preparation method of the above fire-extinguishing material are:

[0022] (1) Detect the pH value of phosphogypsum produced by wet-process phosphoric acid, select phosphogypsum with a pH value of 2 to 3, and perform preliminary screening of the selected phosphogypsum to remove solid impurities; after the screening is completed, put the phosphogypsum into the electric heater In the blast drying box, set the temperature to 100°C and the drying time...

Embodiment 2

[0027] A phosphogypsum-based self-produced gas-expanding slurry fire-fighting material, consisting of the following components and parts by weight: 58 parts of phosphogypsum with a pH of 2 to 3, 28 parts of water, 8 parts of cement, and polyoxyethylene alkyl 0.12 parts of amine, 0.8 parts of hydroxyethyl cellulose, 0.22 parts of acrylic acid, 0.39 parts of sodium methacrylate sulfonate, 0.01 parts of ammonium persulfate, 3.7 parts of sodium bicarbonate, 0.3 parts of micro silicon powder.

[0028] The preparation method of the above-mentioned fire-extinguishing material is completely the same as that of Example 1, so that the expanded slurry fire-extinguishing material B is prepared. The phosphogypsum: water ratio in the fire-extinguishing material B is about 1:0.49, and the expansion ratio is about 3.4.

Embodiment 3

[0030] A phosphogypsum-based self-produced gas-expanding slurry fire-fighting material, consisting of the following components and parts by weight: 60 parts of phosphogypsum with a pH of 2 to 3, 25 parts of water, 8 parts of ordinary Portland cement, and poly 0.07 parts of oxyethylene alkyl amine, 0.7 parts of hydroxyethyl cellulose, 0.22 parts of acrylic acid, 0.39 parts of sodium methacrylate sulfonate, 0.01 parts of ammonium persulfate, 3.4 parts of sodium bicarbonate, 0.3 parts of micro silicon powder.

[0031] The preparation method of the above-mentioned fire-extinguishing material is completely the same as that of Example 1, so that the expanded slurry fire-extinguishing material C is prepared. The phosphogypsum:water ratio in the fire-extinguishing material C is about 1:0.42, and the expansion ratio is about 3.1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com