Bioreactor for treating high-salt organic wastewater based on composite salt-tolerant bacterial strain

A bioreactor and organic wastewater technology, which is applied in the direction of water pollutants, special treatment targets, biological treatment devices, etc., can solve the problems of poisoning ordinary activated sludge microbial strains, unstable treatment effects, and high investment costs. Achieve the effects of increasing volume utilization, improving degradation efficiency, and increasing biomass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

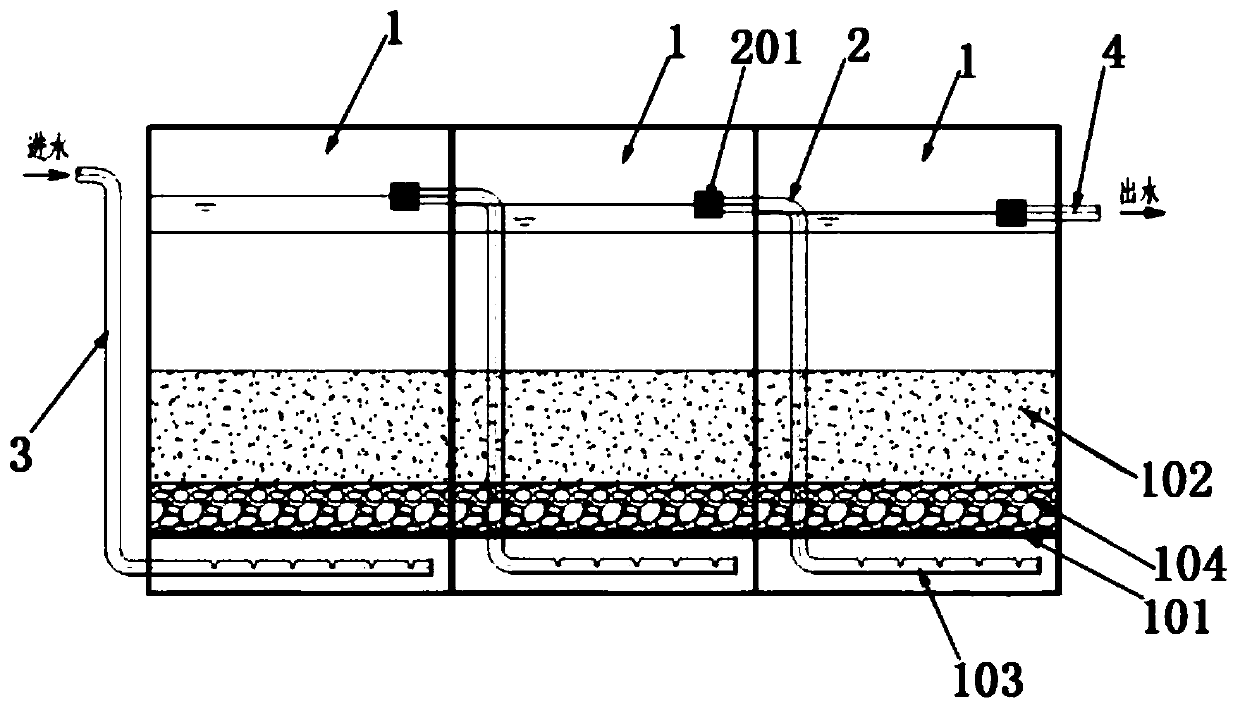

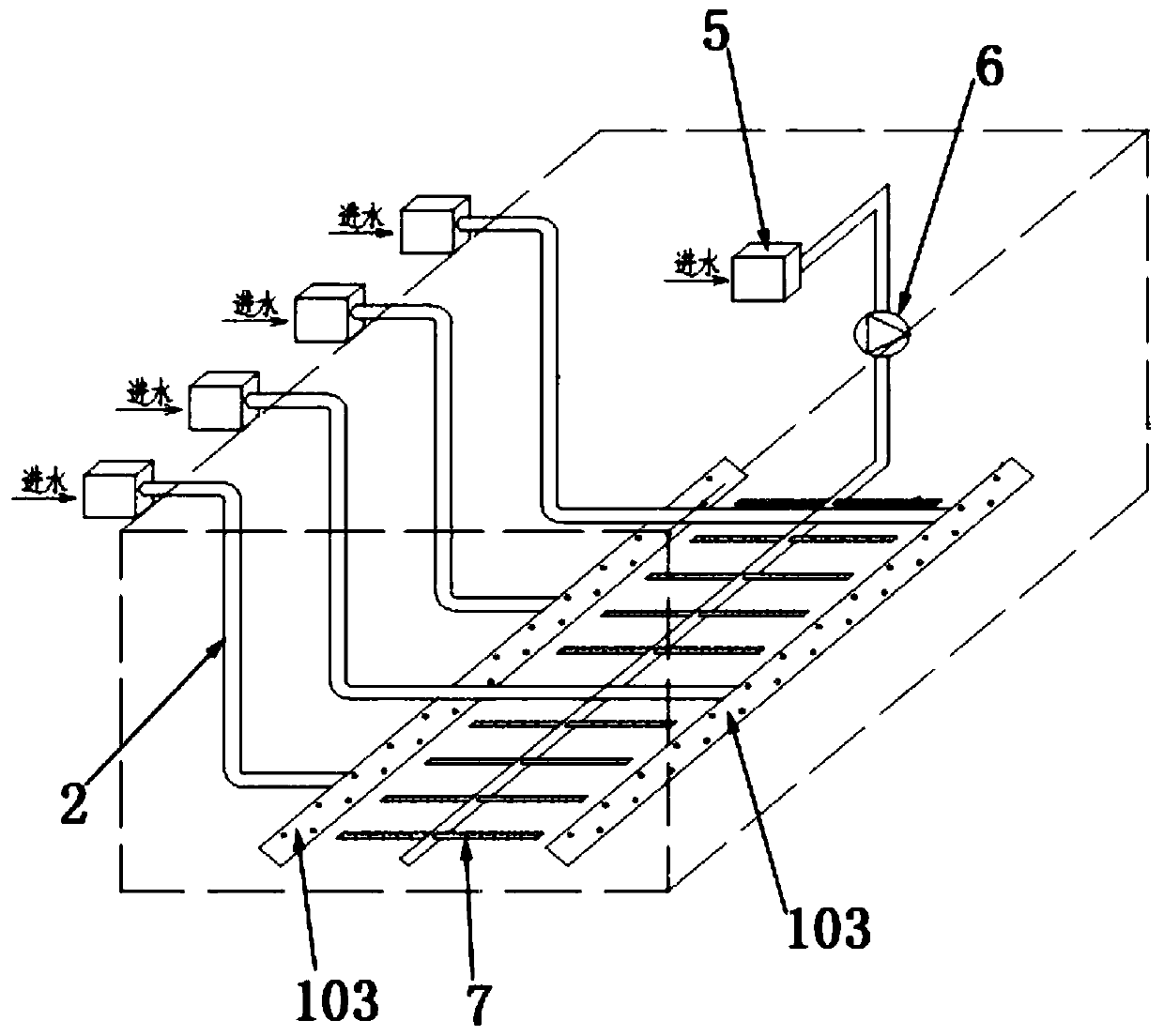

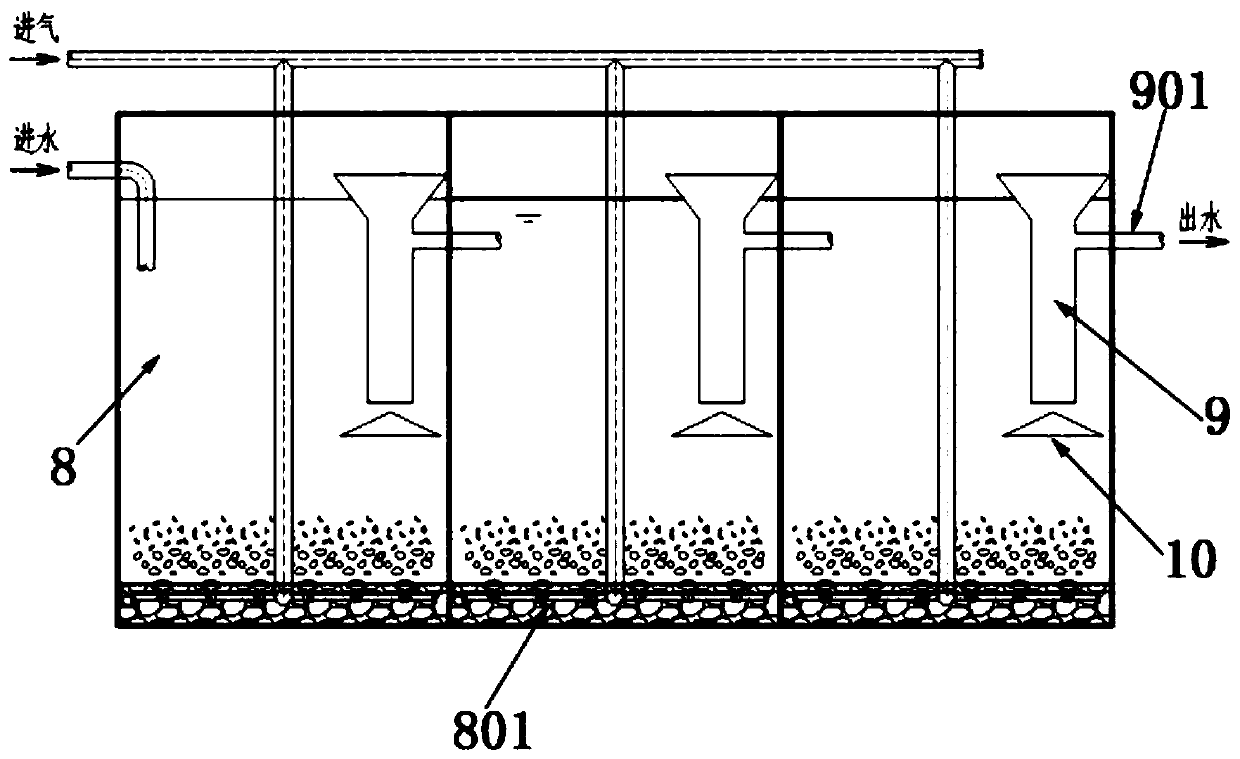

[0037] In this embodiment, the anaerobic sewage treatment device is composed of six stages of anaerobic reactors 1 connected in series, and the aerobic sewage treatment device is composed of three stages of aerobic reactors 8 connected in series. When using the bioreactor of the present application to treat high-salt organic wastewater, first select salt-tolerant anaerobic bacteria and salt-tolerant aerobic bacteria and carry out domestication and cultivation respectively (the selected salt-tolerant anaerobic bacteria and salt-tolerant aerobic bacteria are both It is a compound type of salt-tolerant bacteria, and was purchased from Zhejiang Tianzheng Design Engineering Co., Ltd.). Taking salt-tolerant aerobic bacteria as an example, the domestication and cultivation process is as follows:

[0038] 1. Strain activation: Dissolve aerobic strain powder in clear water at about 30°C, add nutrient solution, and continue aeration for 24 hours to activate aerobic strains to obtain an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com