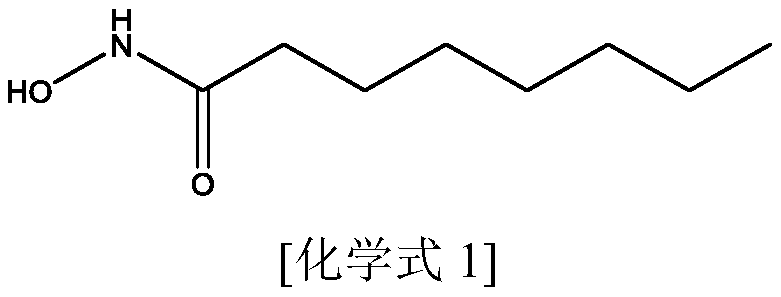

Preparation technology of caprylhydroxamic acid

A technology for the preparation of caprylyl hydroxamic acid, which is applied in the field of preparation of caprylyl hydroxamic acid, can solve the problems of low yield, achieve the effects of improving yield and purity, wide temperature range, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A kind of preparation technology of caprylyl hydroxamic acid, the mol ratio of each material that adopts is as follows:

[0042] The molar ratio of compound 2 to composite catalyst is 1:0.014;

[0043] In the composite catalyst, the mol ratio of sodium acetate to sodium carbonate is 1:0.4;

[0044] The molar ratio of compound 2 to hydroxylamine is 1:1.003;

[0045] The molar ratio of compound 1 to ethanol is 1:1.1,

[0046] Specifically, the following steps are included:

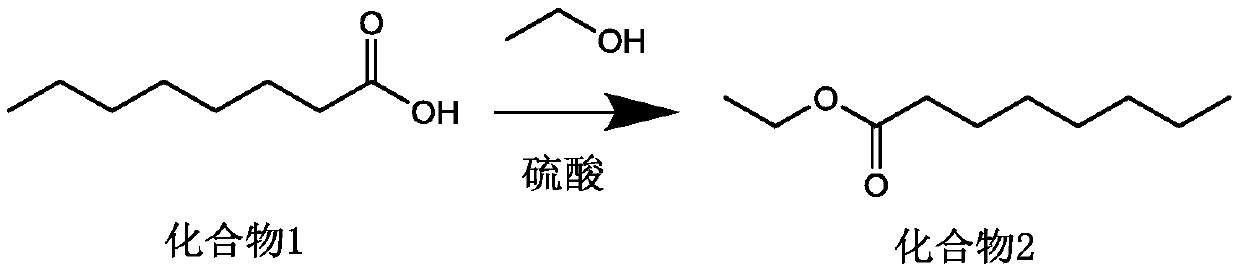

[0047] (a) preparation of n-octanoic acid ethyl ester

[0048] Mix 14.421g (0.1mol, 1.0eq) of compound 1 and 5.068g (0.11mol, 1.1eq) of ethanol, add 1mL of sulfuric acid, heat to reflux for 5 hours, neutralize with sodium hydroxide solution, and distill under reduced pressure to obtain 16.167g Colorless liquid product, based on compound 2, the purity of the colorless liquid product is 99.2%, and the yield is 93.1%;

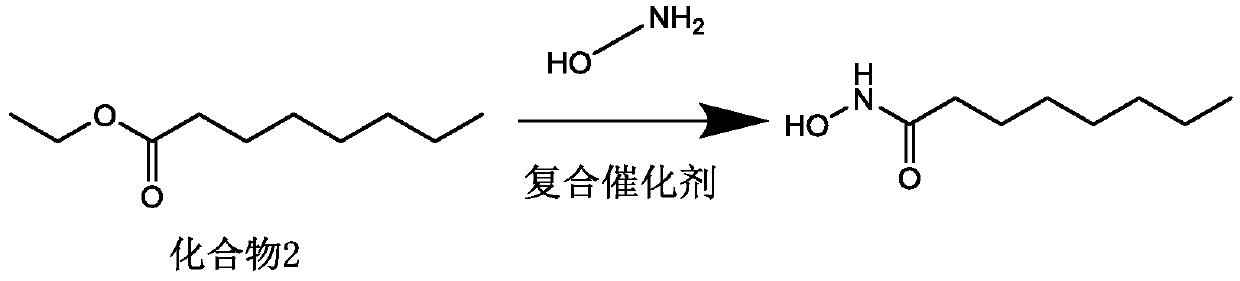

[0049] (b) Preparation of Caprylyl Hydroxamic Acid

[0050] Mix 6.169g (0.09337...

Embodiment 2

[0052] A kind of preparation technology of caprylyl hydroxamic acid, the mol ratio of each material that adopts is as follows:

[0053] The molar ratio of compound 2 to composite catalyst is 1:0.03;

[0054] In the composite catalyst, the mol ratio of sodium acetate to sodium carbonate is 1:0.5;

[0055] The molar ratio of compound 2 to hydroxylamine is 1:1.004;

[0056] The molar ratio of compound 1 to ethanol is 1:1.2,

[0057] Specifically, the following steps are included:

[0058] (a) preparation of n-octanoic acid ethyl ester

[0059] Mix 14.421g (0.1mol, 1.0eq) of compound 1 and 5.528g (0.12mol, 1.2eq) of ethanol, add 1mL of sulfuric acid, heat to reflux for 5 hours, neutralize with sodium hydroxide solution, and distill under reduced pressure to obtain 16.294g Colorless liquid product, based on compound 2, the purity of the colorless liquid product is 99.8%, and the yield is 94.4%;

[0060] (b) Preparation of Caprylyl Hydroxamic Acid

[0061] Mix 6.261g (0.094778...

Embodiment 3

[0063] A kind of preparation technology of caprylyl hydroxamic acid, the mol ratio of each material that adopts is as follows:

[0064] The molar ratio of compound 2 to composite catalyst is 1:0.036;

[0065] In the composite catalyst, the mol ratio of sodium acetate to sodium carbonate is 1:0.6;

[0066] The molar ratio of compound 2 to hydroxylamine is 1:1.005;

[0067] The molar ratio of compound 1 to ethanol is 1:1.3,

[0068] Specifically, the following steps are included:

[0069] (a) preparation of n-octanoic acid ethyl ester

[0070] Mix 14.421g (0.1mol, 1.0eq) of compound 1 and 5.989g (0.13mol, 1.3eq) of ethanol, add 1mL of sulfuric acid, heat to reflux for 5 hours, neutralize with sodium hydroxide solution, and distill under reduced pressure to obtain 16.395g Colorless liquid product, based on compound 2, the purity of the colorless liquid product is 99.5%, and the yield is 94.7%;

[0071] (b) Preparation of Caprylyl Hydroxamic Acid

[0072] Mix 6.287g (0.09517...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com