Space-level cyanate resin based on nanoparticle modification, and preparation method thereof

A cyanate ester resin and nanoparticle technology, applied in the field of space-grade cyanate ester resin and its preparation, can solve problems such as the decline of mechanical properties, and achieve the effects of excellent mechanics and excellent dimensional stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

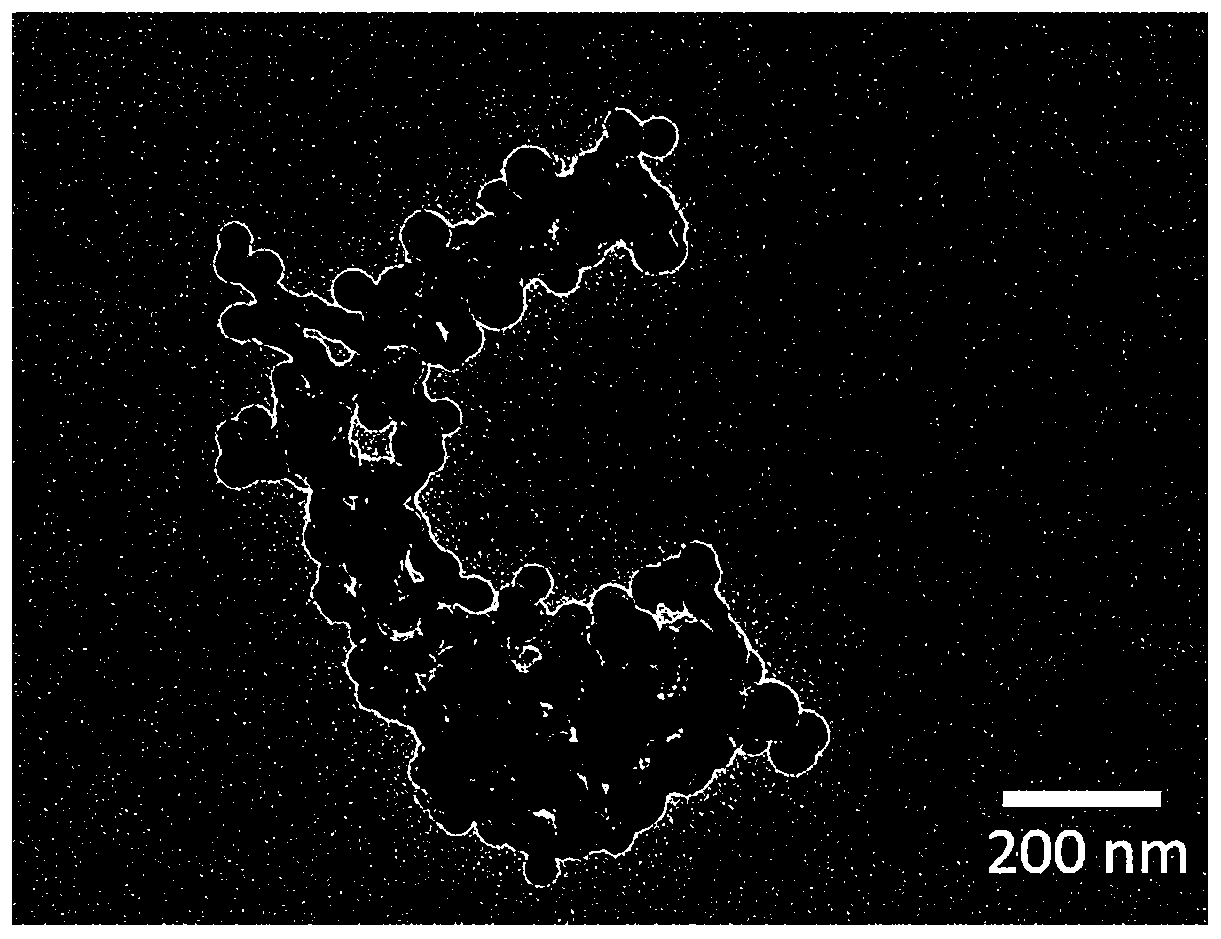

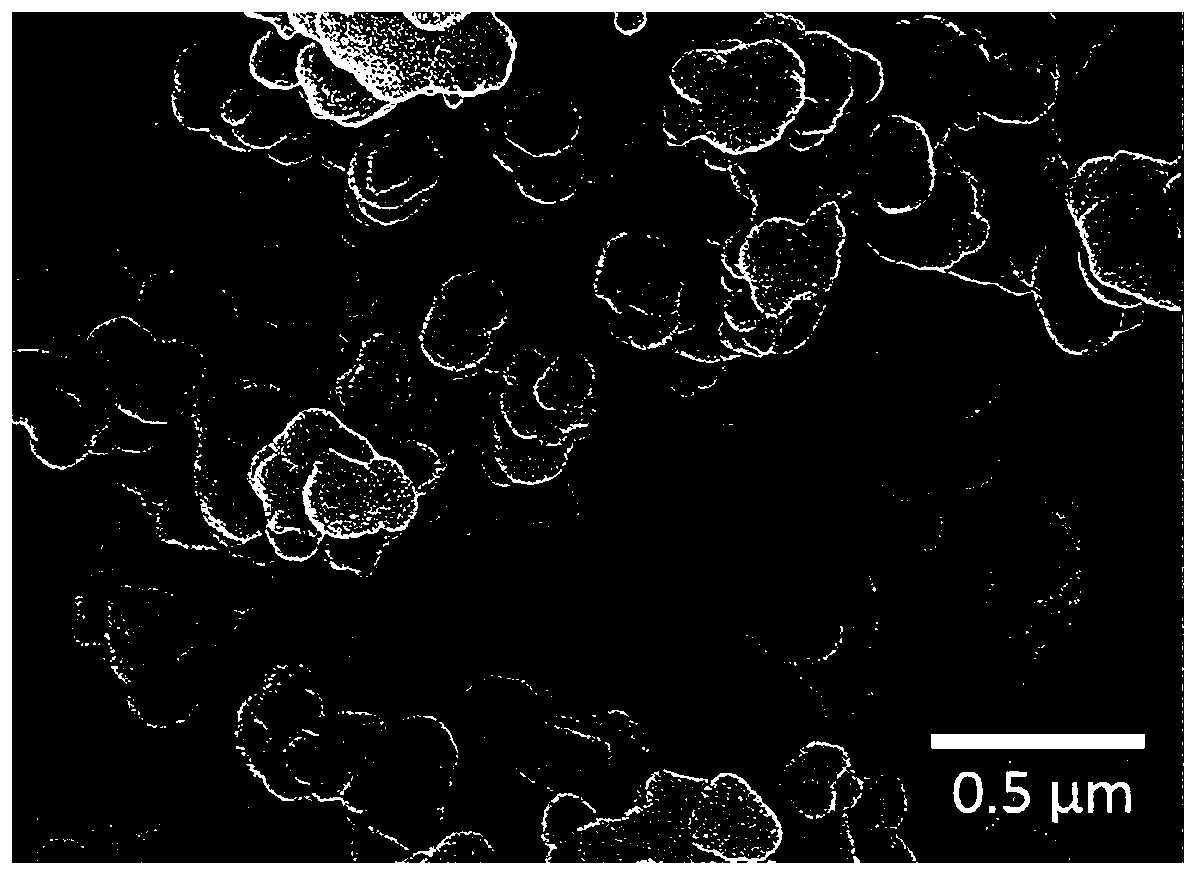

Image

Examples

Embodiment 1

[0028] This embodiment relates to a space-grade cyanate resin modified by nanoparticles and a preparation method thereof. The matrix resin is a cyanate resin, and the reinforcing material is a cyanate nanoparticle. Concrete preparation comprises the following steps:

[0029] Add 200 g of cyanate monomer into 800 g of xylene solution, and stir mechanically at 80° C. for 2 hours. The cyanate monomer is completely dissolved, and solution A is obtained.

[0030] Add 0.2 g of zinc acetylacetonate and 0.2 g of nonylphenol into solution A respectively, mechanically stir at 90° C. for 2 h, raise the temperature to 120° C. and mechanically stir for 3 h to obtain solution B.

[0031] Place the solution B in a rotary evaporator with a vacuum degree of ≤-0.97MPa, and rotate at 100°C for 2 hours to obtain a solution containing crude cyanate ester nanoparticles.

[0032] The solution containing the crude product of cyanate ester nanoparticles is placed in a centrifuge at a rotational speed...

Embodiment 2

[0037] This embodiment relates to a space-grade cyanate resin modified by nanoparticles and a preparation method thereof. The matrix resin is a cyanate resin, and the reinforcing material is a cyanate nanoparticle. Concrete preparation comprises the following steps:

[0038] Add 100 g of cyanate monomer into 900 g of xylene solution, and mechanically stir at 80° C. for 1 hour to completely dissolve the cyanate monomer to obtain solution A.

[0039] Add 0.2 g of zinc acetylacetonate and 0.2 g of nonylphenol into solution A respectively, mechanically stir at 90° C. for 1.5 h, raise the temperature to 120° C. and mechanically stir for 1 h to obtain solution B.

[0040] The solution B was placed in a rotary evaporator with a vacuum degree of ≤-0.97 MPa, and was rotated at 100° C. for 1.5 h to obtain a solution containing crude cyanate ester nanoparticles.

[0041] The solution containing the crude product of cyanate ester nanoparticles is placed in a centrifuge at a rotational sp...

Embodiment 3

[0046] This embodiment relates to a space-grade cyanate resin modified by nanoparticles and a preparation method thereof. The matrix resin is a cyanate resin, and the reinforcing material is a cyanate nanoparticle. Concrete preparation comprises the following steps:

[0047] Add 150 g of cyanate monomer into 850 g of xylene solution, and stir mechanically at 80° C. for 3 hours to completely dissolve the cyanate monomer to obtain solution A.

[0048] Add 0.25g of zinc acetylacetonate and 0.25g of nonylphenol into solution A respectively, mechanically stir at 90°C for 1 hour, raise the temperature to 120°C and stir mechanically for 2 hours to obtain solution B.

[0049] The solution B was placed in a rotary evaporator with a vacuum degree of ≤-0.97MPa, and was rotated at 100° C. for 1 hour to obtain a solution containing crude cyanate ester nanoparticles.

[0050] The solution containing the crude product of cyanate ester nanoparticles was placed in a centrifuge at a speed of 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com