Environment-friendly water-based flexographic printing UV ink

A water-based, flexo printing technology, used in inks, household appliances, applications, etc., can solve problems such as inability to dry and slow product drying, achieve fast curing speed, improve grinding efficiency, and good gloss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

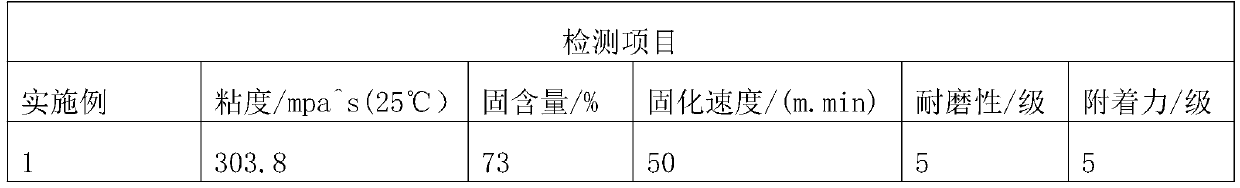

Embodiment 1

[0027]An environmentally friendly water-based flexo printing UV ink is prepared from the following components in mass fractions: 30% of UV-curable water-based blended resin, 36% of photoinitiator, 2% of active diluent; 10% of deionized water, organic 2% of pigment, 3% of dispersant, 1% of anti-sticking agent, 1% of anti-scratch agent, and 15% of cosolvent; Modified acrylate resin is blended, and the blending ratio of the polycarbonate urethane acrylate (PCDL-PUA) and silyl-modified acrylate resin is 0.5:2.5; the photoinitiator is composed of 2-hydroxy -Methylphenylpropan-1-one, 1-hydroxy-cyclohexyl-phenylmethanone, 2-phenylbenzyl 2-dimethylamine-1-(4-morpholinebenzylphenyl) butanone and 2 -Methyl 1-(4-methylthiophenyl)-2-morpholinyl-1-propanone mixed with four compounds.

[0028] Described photoinitiator is made of 2-hydroxyl-methylphenyl propane-1-ketone, 1-hydroxyl-cyclohexyl-phenyl ketone, 2-phenylbenzyl 2-dimethylamine-1-(4-methanol It is prepared by mixing four compound...

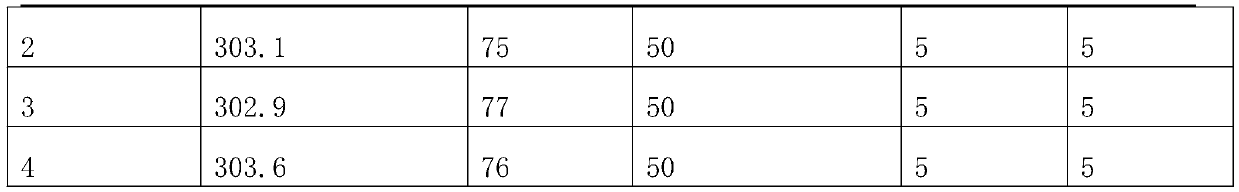

Embodiment 2

[0034] An environmentally friendly water-based flexographic UV ink is prepared from the following components in mass fractions: 50% UV-curable water-based blend resin, 25% photoinitiator, 2% reactive diluent; 3% deionized water, organic 1% of pigment, 2% of dispersant, 0.5% of anti-sticking agent, 0.5% of anti-scratch agent, 16% of co-solvent; the UV curable water-based blended resin is composed of polycarbonate-based polyurethane acrylate (PCDL-PUA) and silane-based Modified acrylate resin is blended, and the blending ratio of the polycarbonate urethane acrylate (PCDL-PUA) and silyl-modified acrylate resin is 1.2:3.5; the photoinitiator is composed of 2-hydroxy -Methylphenylpropan-1-one, 1-hydroxy-cyclohexyl-phenylmethanone, 2-phenylbenzyl 2-dimethylamine-1-(4-morpholinebenzylphenyl) butanone and 2 -Methyl 1-(4-methylthiophenyl)-2-morpholinyl-1-propanone mixed with four compounds.

[0035] Described photoinitiator is made of 2-hydroxyl-methylphenyl propane-1-ketone, 1-hydrox...

Embodiment 3

[0042] An environmentally friendly water-based flexographic UV ink is prepared from the following components in mass fractions: 60% UV-curable water-based blend resin, 4% photoinitiator, 8% reactive diluent; 6% deionized water, organic 2% of pigment, 3% of dispersant, 1% of anti-sticking agent, 1% of anti-scratch agent, and 15% of cosolvent; Modified acrylate resin is blended, and the blending ratio of the polycarbonate urethane acrylate (PCDL-PUA) and silane-based modified acrylate resin is 0.5:3.5; the photoinitiator is composed of 2-hydroxy -Methylphenylpropan-1-one, 1-hydroxy-cyclohexyl-phenylmethanone, 2-phenylbenzyl 2-dimethylamine-1-(4-morpholinebenzylphenyl) butanone and 2 -Methyl 1-(4-methylthiophenyl)-2-morpholinyl-1-propanone mixed with four compounds.

[0043] Described photoinitiator is made of 2-hydroxyl-methylphenyl propane-1-ketone, 1-hydroxyl-cyclohexyl-phenyl ketone, 2-phenylbenzyl 2-dimethylamine-1-(4-methanol It is prepared by mixing four compounds 1:1:1:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com