Carbon nanotube/nickel cobaltate lithium ion battery negative electrode material and preparation method thereof

A lithium-ion battery and carbon nanotube technology, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems that fossil energy cannot meet energy demand, achieve excellent cycle performance, simple process, and improve material performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Mix 1mmol nickel nitrate hexahydrate and 2mmol cobalt nitrate hexahydrate, dissolve in 25 milliliters of dehydrated ethanol solution, then add 5 milliliters of deionized aqueous solution containing 0.8 gram of cetyltrimethylammonium bromide, then Add 0.0646 g of carbon nanotubes (CNTs), sonicate for 30 minutes, and stir for 1 hour to obtain a mixed solution A;

[0028] (2) Pour the mixed solution into a 50 ml reactor liner, then heat it in water at 180°C for 6 hours, and then filter and dry to obtain the CNTs / nickel cobaltate precursor;

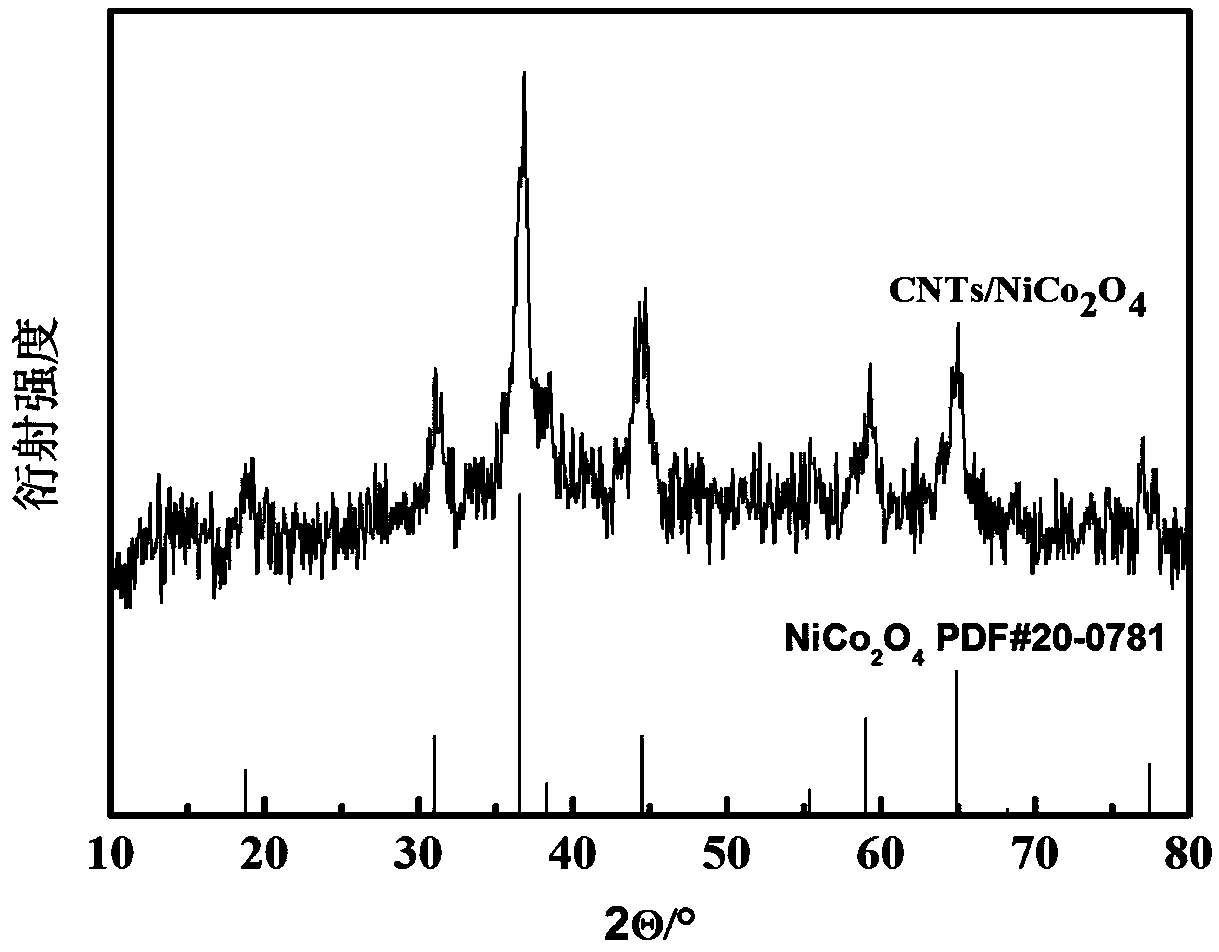

[0029] (3) The CNTs / nickel cobaltate precursor was calcined at 450°C in an air atmosphere at a heating rate of 2°C / min for 2 hours to obtain CNTs / NiCo 2 o 4 composite materials;

Embodiment 2

[0031] (1) Mix 1 mmol nickel nitrate hexahydrate and 2 mmol cobalt nitrate hexahydrate, dissolve in 5 ml deionized water, then add 25 ml hexadecyl trimethylammonium bromide containing 0.8 g cetyl trimethyl ammonium bromide Ammonium bromide solution, then add 0.0646 grams of carbon nanotubes (CNTs), ultrasonic 30 minutes, stirred for 1 hour, to obtain a mixed solution A;

[0032] (2) Pour the mixed solution into a 50 ml reactor liner, then heat it in water at 180°C for 6 hours, and then filter and dry to obtain the CNTs / nickel cobaltate precursor;

[0033] (3) The CNTs / nickel cobaltate precursor was calcined at 450°C in an air atmosphere at a heating rate of 2°C / min for 2 hours to obtain CNTs / NiCo 2 o 4 composite materials;

Embodiment 3

[0035] (1) 1mmol nickel nitrate hexahydrate, 2mmol cobalt nitrate hexahydrate, and 0.8 gram of cetyltrimethylammonium bromide were dissolved in a mixed solution containing 25 milliliters of absolute ethanol and 5 milliliters of deionized water. Then add 0.0646 g of carbon nanotubes (CNTs), ultrasonic for 30 minutes, and stir for 1 hour to obtain a mixed solution A;

[0036] (2) Pour the mixed solution into a 50 ml reactor liner, then heat it in water at 180°C for 6 hours, and then filter and dry to obtain the CNTs / nickel cobaltate precursor;

[0037] (3) The CNTs / nickel cobaltate precursor was calcined at 450°C in an air atmosphere at a heating rate of 2°C / min for 2 hours to obtain CNTs / NiCo2 o 4 composite materials;

PUM

| Property | Measurement | Unit |

|---|---|---|

| First discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com