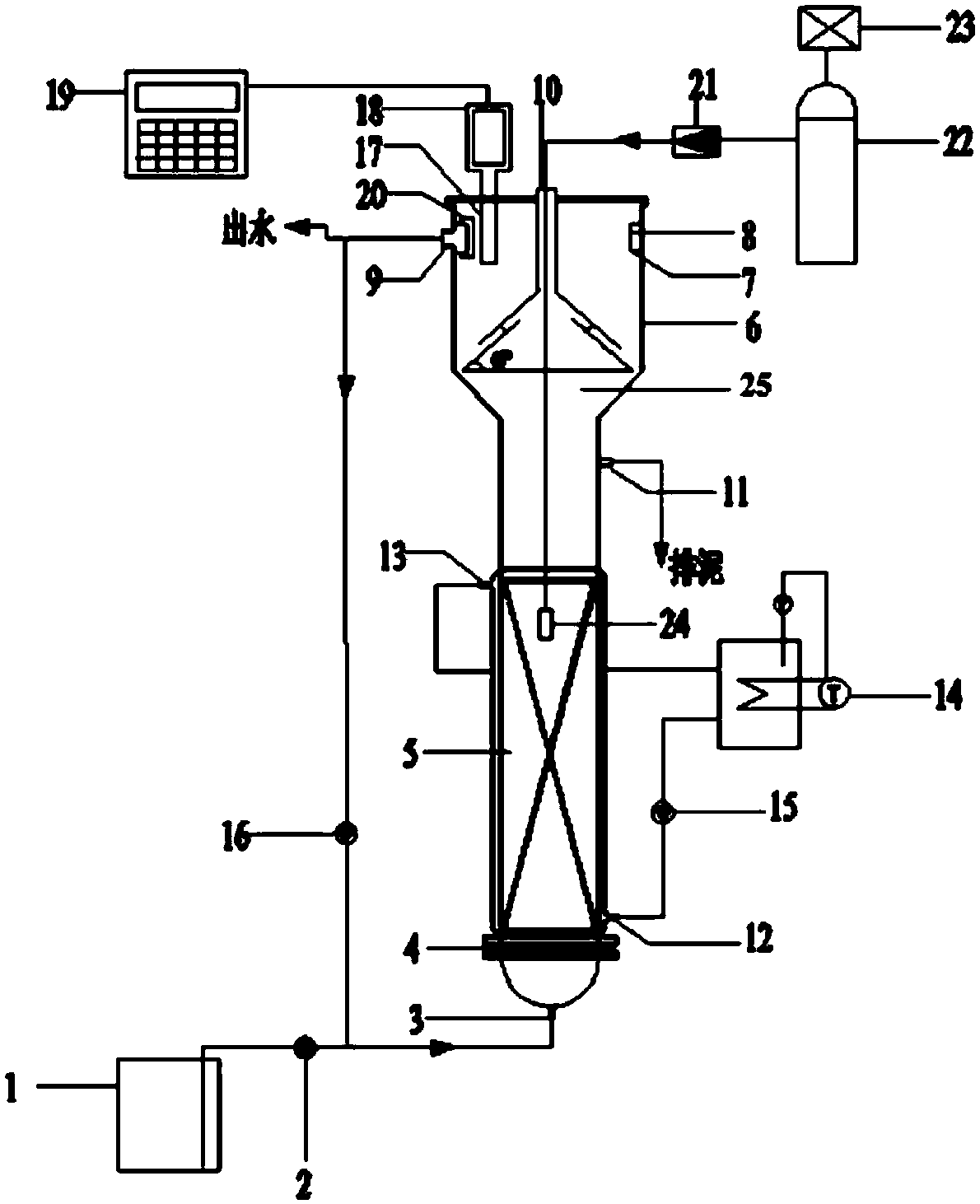

Denitrification treatment method of high-concentration nitrate wastewater

A treatment method and nitrate technology, applied in water/sewage treatment, anaerobic digestion treatment, chemical instruments and methods, etc., can solve the problems of denitrifying bacteria activity inhibition, secondary pollution of zinc powder, etc., to prevent the loss of filler, The effect of continuous and stable sludge discharge and preventing sludge from clogging the filter screen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The concentration of nitrate in the industrial wastewater processed in this embodiment is 14344mg / L (NO 3 - The N concentration is 3238mg / L), the COD concentration is 2600mg / L, and the pH is 0.2.

[0058] First, the industrial wastewater is pretreated, including:

[0059] (1) adding alkali (NaOH) to the industrial wastewater to adjust the pH of the influent to 2;

[0060] (2) Add methanol to make COD be 12410mg / L in the waste water after adjusting pH in step (1), COD:NO 3 - The mass concentration ratio of N is 3.8;

[0061] (3) Add nitrogen nutrient salt (ammonia or urea), phosphorus nutrient salt (KH 2 PO 4 or Na 3 PO 4 ) is respectively to make in terms of N elements, the concentration of N is 205mg / L, in terms of P elements, the concentration of P is 41mg / L, and the ratio of the mass concentration of COD:N:P is 302:5:1; Obtain pretreatment waste water.

[0062] (4) The pretreated waste water is passed into the anoxic fluidized bed reactor with a certain flo...

Embodiment 2

[0066] The industrial waste water nitrate content of processing in the present embodiment is 30443mg / L (NO 3 - The N concentration is 6874mg / L), the COD concentration is 5700mg / L, and the pH is 0.4.

[0067] First, the industrial wastewater is pretreated, including:

[0068] (1) adding alkali (NaOH) to the wastewater to adjust the pH of the influent to 2.3;

[0069] (2) Add supplementary carbon source (methanol) to the waste water after pH adjustment in step (1) to make COD 24059mg / L, COD:NO 3 - The mass concentration ratio of N is 3.5;

[0070] (3) Add nitrogen nutrient salt (ammonia or urea), phosphorus nutrient salt (KH 2 PO 4 or Na 3 PO 4 ) is respectively to make in terms of N elements, the concentration of N is 301mg / L, in terms of P elements, the concentration of P is 60mg / L, and the ratio of the mass concentration of COD:N:P is 400:5:1, obtain pretreatment waste water;

[0071] (4) The pretreated waste water is passed into the anoxic fluidized bed reactor wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com