Catalyst used for alkene polymerization reaction, preparation method and composite catalyst

A composite catalyst and olefin polymerization technology, applied in the field of olefin polymerization, can solve the problems of high polymer fine powder, broken, and increased fine powder content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] (1) Preparation of catalyst

[0087] to 2.5m 3 1300L tetrahydrofuran, 7 liters of TiCl 4 , 7.0 kg TiCl 3 , 53 kg anhydrous MgCl 2 , 0.4 kg of carbon nanotubes (with a diameter of 20-50 nm and an aspect ratio exceeding 100), heated to 67° C. under stirring, and reacted at this temperature for 6 hours at a constant temperature. Cool down to 35°C, then add 82 kg of silica gel (Cabot Corporation TS-610, particle size 0.05-0.5 microns), keep the temperature at 65°C, stir for 3 hours, then cool down to 50°C, and start using a centrifugal spray dryer for the slurry Spray drying was carried out under spray conditions: inlet temperature 150° C., outlet temperature 100° C. to obtain 220 kg of solid catalyst components, wherein the titanium content was 2.19 wt%.

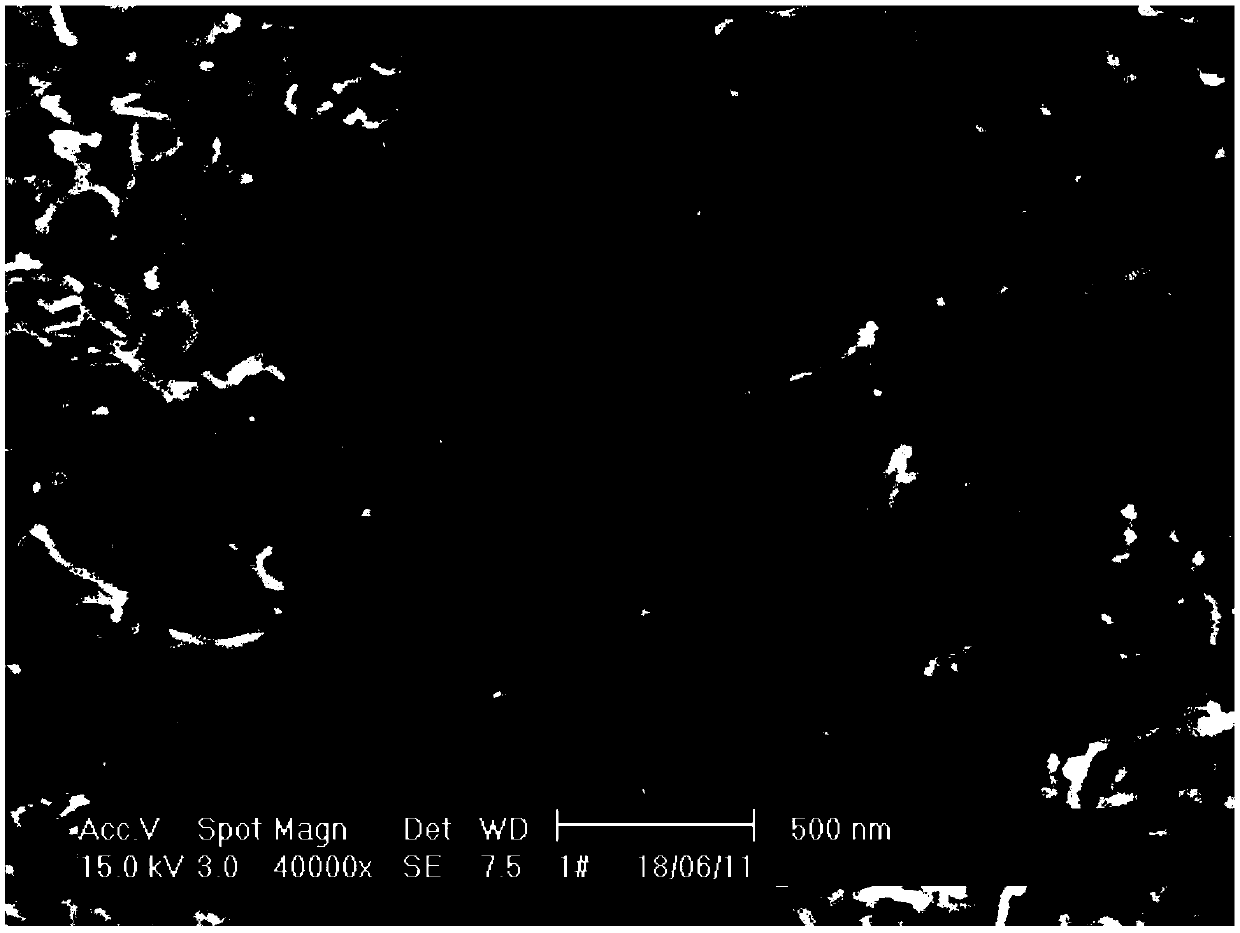

[0088] figure 1 It is an image obtained by using the catalyst particles obtained in Example 1, stirring and washing in ethanol, and then filtering through a 100-mesh filter screen, and observing it under a scanning ...

Embodiment 2

[0095] (1) The preparation of the catalyst is the same as in Example 1. Only the amount of carbon nanotubes was adjusted to 0.3 kg, the amount of magnesium chloride was adjusted to 54 kg, and the titanium content of the obtained solid catalyst component was 2.29 wt%.

[0096] (2) Ethylene slurry polymerization is the same as that in Example 1, the catalyst element content is shown in Table 1, and the polymerization results are shown in Table 2.

Embodiment 3

[0098] (1) Preparation of catalyst

[0099] Add 0.7 grams of TiCl successively to a 250ml four-neck bottle that has been purged with nitrogen 3 , 3.5 g anhydrous MgCl 2 , 130ml tetrahydrofuran, heated to 66°C under stirring, and reacted at this temperature for 3 hours. Cool down to 35°C, add 0.2 g of carbon nanotubes, and continue stirring for 1 hour.

[0100] Add 7 grams of silica gel (Cabot Corporation TS-610, particle size 0.05-0.5 μm) into a 250 ml four-neck bottle that has been purged with nitrogen, add the cooled mother liquor, keep the temperature at 35° C., and stir for 1 hour. The slurry was spray-dried with a spray dryer, spraying conditions: inlet temperature 140°C, outlet temperature 102°C, to obtain a solid catalyst component, wherein the titanium content was 2.17wt%.

[0101] (2) Ethylene slurry polymerization is the same as that in Example 1, the catalyst element content is shown in Table 1, and the polymerization results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com