Preparation method of glass fiber reinforced plastic flame-retardant anti-corrosion purline material

A glass fiber reinforced plastic and purlin technology is applied in the field of preparation of glass fiber reinforced plastic flame-retardant and anti-corrosion purlin materials, and achieves the effects of good adhesion, good resilience and good corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

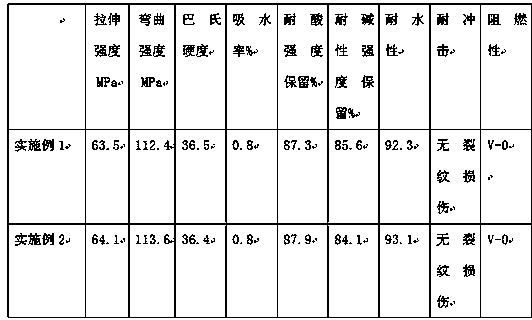

Examples

Embodiment 1

[0019] A preparation method of FRP flame-retardant and anti-corrosion purlin material, the specific method is as follows:

[0020] (1) In terms of parts by weight, 23 parts of monomer dimethyldichlorosilane, 17 parts of diphenyldichlorosilane, 87 parts of phenyltrichlorosilane, 6.7 parts of methyltrichlorosilane and 110 parts of xylene 81.1 parts of xylene and 71.31 parts of water are added to the hydrolysis kettle, and the mixed monomer is added dropwise under stirring. The temperature is controlled at 20 ° C, the dropping time is 5.5 hours, and then the temperature is raised to 120 ° C Continue to react for 1 hour, let stand to separate layers, remove the water in the lower layer, and finally remove the solvent, residual water and low molecular weight substances under reduced pressure to obtain the silicone resin prepolymer;

[0021] (2) Synthesize unsaturated polyester with diethylene glycol, neopentyl glycol, adipic acid, tetrahydrophthalic anhydride and maleic anhydride a...

Embodiment 2

[0028] A preparation method of FRP flame-retardant and anti-corrosion purlin material, the specific method is as follows:

[0029] (1) First, in parts by weight, 35.4 parts of monomer dimethyldichlorosilane, 19 parts of diphenyldichlorosilane, 95.1 parts of phenyltrichlorosilane, 11.3 parts of methyltrichlorosilane and 122 parts of xylene 81.1 parts of xylene and 71.31 parts of water were added to the hydrolysis kettle, and the mixed monomer was added dropwise under stirring. The temperature was controlled at 30°C, and the dropping time was 5h, and then the temperature was raised to 120°C to continue React for 1 hour, let stand to separate layers, remove the lower layer of water, and finally remove the solvent, residual water and low molecular weight substances under reduced pressure to obtain the silicone resin prepolymer;

[0030](2) Synthesize unsaturated polyester with diethylene glycol, neopentyl glycol, adipic acid, tetrahydrophthalic anhydride and maleic anhydride as ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com