Etching solution for etching indium tin oxide semiconductor transparent conductive film

A technology of transparent conductive film and indium tin oxide, which is applied in surface etching compositions, chemical instruments and methods, etc., can solve the problem of difficulty in controlling the etching angle and the etching amount of the metal layer, affecting the repeatability of the effect, and unreasonable formula settings. and other problems, to achieve the effect of rapid and complete biodegradation, clear line edges without side etching, and stable etching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

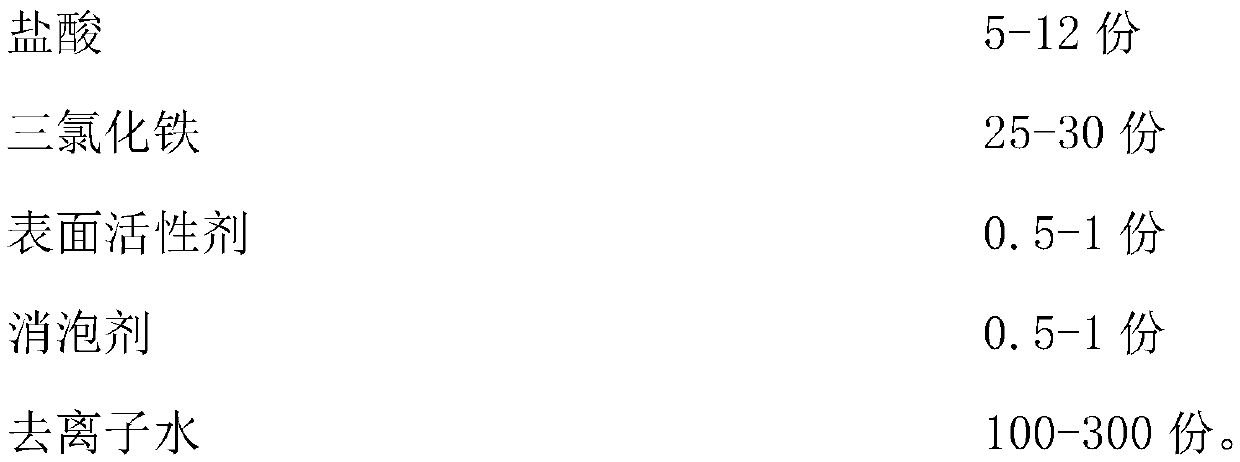

[0017] An etchant for etching transparent conductive films of indium tin oxide semiconductors, characterized in that, calculated in parts by weight, comprising:

[0018]

[0019] Etch the ITO film of the product of this example, and it will be etched clean at 25°C for 1 minute, with complete graphics, no damage to the photoresist, and good protection of the etched lines. Nothing changes within the segment.

Embodiment 2

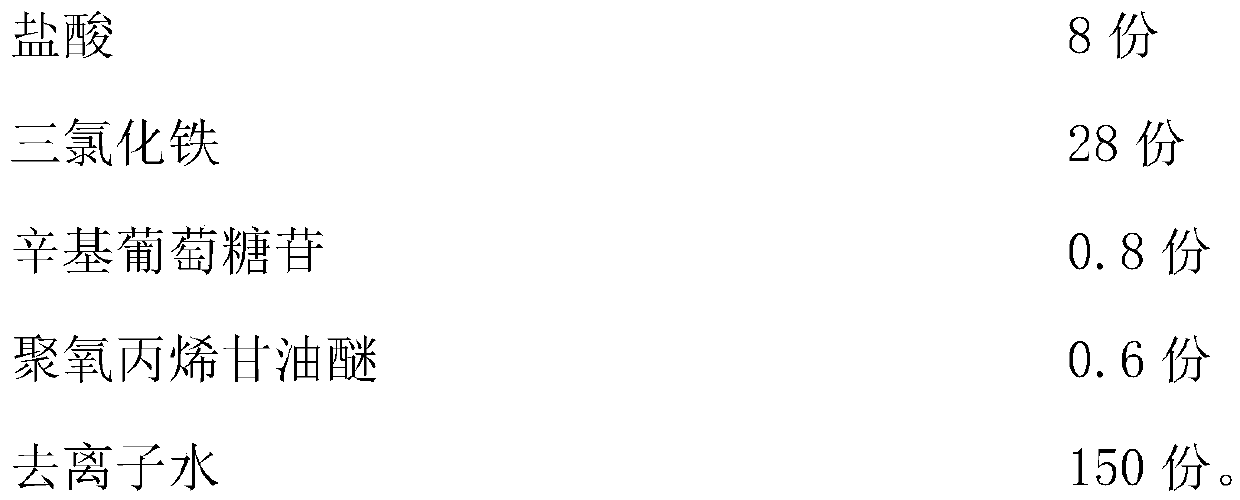

[0021] An etchant for etching transparent conductive films of indium tin oxide semiconductors, characterized in that, calculated in parts by weight, comprising:

[0022]

[0023] Etch the ITO film of the product of this example, and it will be etched clean after 3 minutes at 25°C, with complete graphics, no damage to the photoresist, and good protection of the etched lines. Nothing changes within the segment.

Embodiment 3

[0025] An etchant for etching transparent conductive films of indium tin oxide semiconductors, characterized in that, calculated in parts by weight, comprising:

[0026]

[0027] The product of this example is etched on the ITO film, and it is etched clean at 25°C for 6 minutes. Nothing changes within the segment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com