Device and method of measuring mercury content in smoke

A content and flue gas technology, applied in the field of real-time rapid detection of mercury in flue gas, can solve the problems of slow heat release, low enrichment efficiency, poor measurement accuracy, etc., to increase surface area and density, improve detection rate, and ensure measurement The effect of synchronous results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

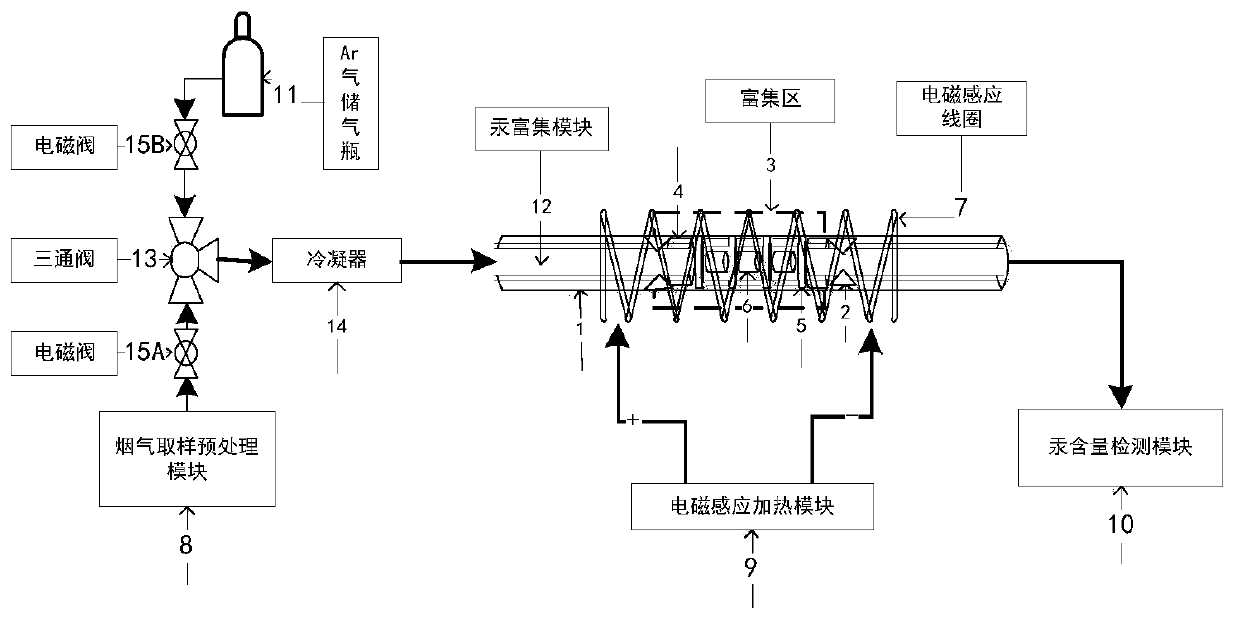

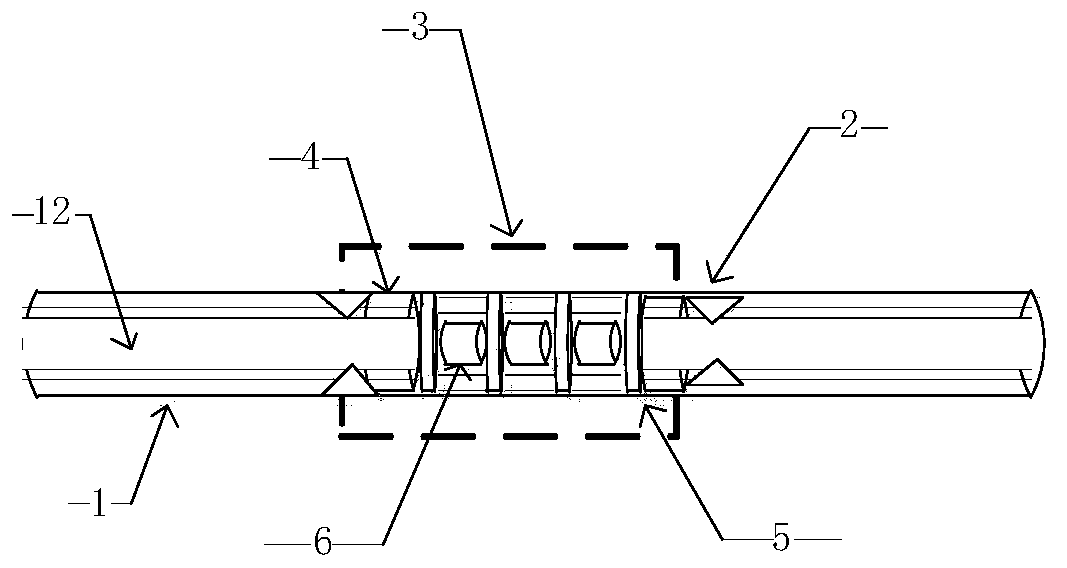

[0036] combine as figure 1 Described overall device, the mercury concentration is 20ng / m 3 The mercury-containing flue gas passes through the flue gas sampling pretreatment module at a flow rate of 1L / min to filter out dust and particulate matter in the flue gas, and the mercury gas in the mercury-containing flue gas passes through the condenser to cool the flue gas, and then passes through the Enter the mercury enrichment module containing 4 gold silk cakes and 3 gold silk ball columns as an enrichment area for enrichment. The time for introducing mercury-containing flue gas is 60s. After the enrichment is stopped, the electromagnetic induction heating module is turned on. , using a 9-turn electromagnetic induction coil to heat the enrichment area, the heating time is 70s, the temperature is controlled at 700°C to 900°C, after the electromagnetic induction heating is stopped, 300ml / min of argon carrier gas is introduced, and the argon gas is used to Load the mercury released...

Embodiment 2

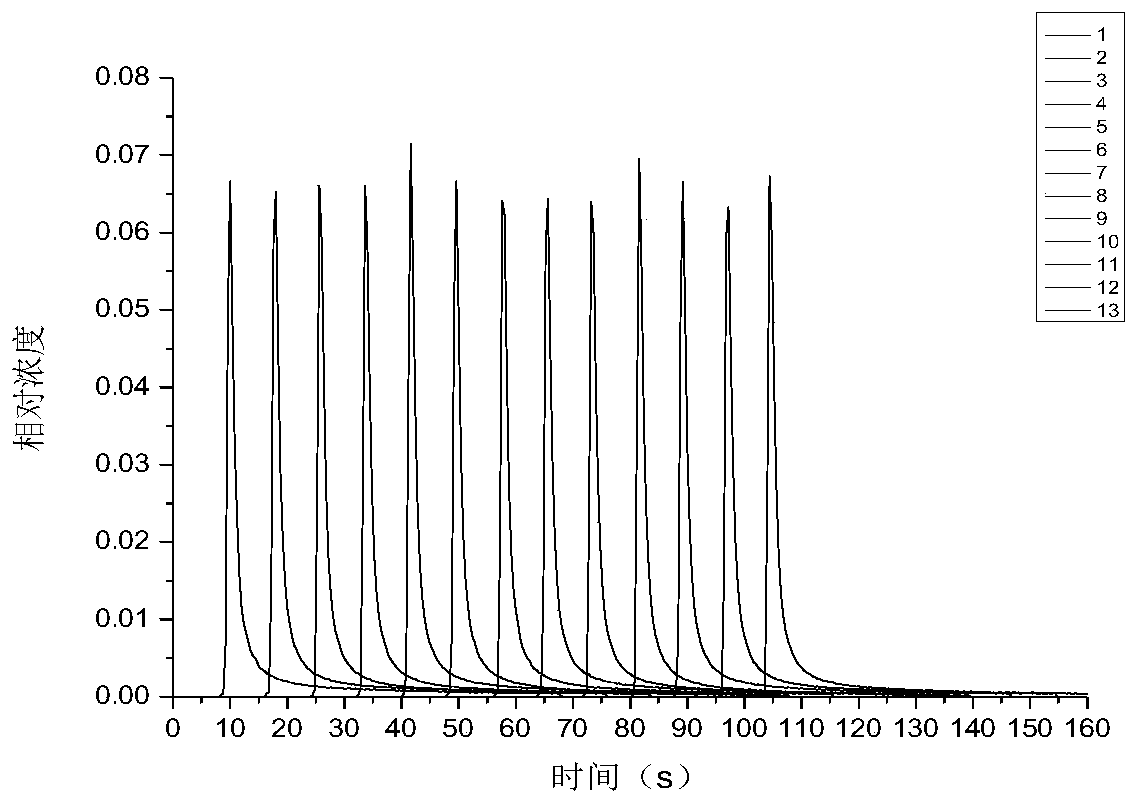

[0038] combine as figure 1 Described overall device, the mercury concentration is 20ng / m 3 The mercury-containing flue gas passes through the flue gas sampling pretreatment module at different flow rates. The mercury-containing flue gas flow rate ranges from 250mL / min to 2L / min. Each experiment increases the flow rate at an interval of 250mL / min to filter out the flue gas. Dust, particulate matter, etc., the mercury gas in the mercury-containing flue gas passes through the condenser to cool the flue gas, and then passes it into the mercury enrichment module containing 4 gold silk cakes and 3 gold silk ball columns as an enrichment area Enrichment is carried out in the middle, and the time for introducing mercury-containing flue gas is 60s. After the enrichment is stopped, the electromagnetic induction heating module is turned on, and a 9-turn electromagnetic induction coil is used to heat the enrichment area. The heating time is 70s, and the temperature is controlled at 700 ℃...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com