CPU top cover

A cover and cover technology, applied in the field of CPU, can solve problems such as troublesome replacement or maintenance and upgrade of CPU, leakage of liquid gold, and inability to meet heat dissipation requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

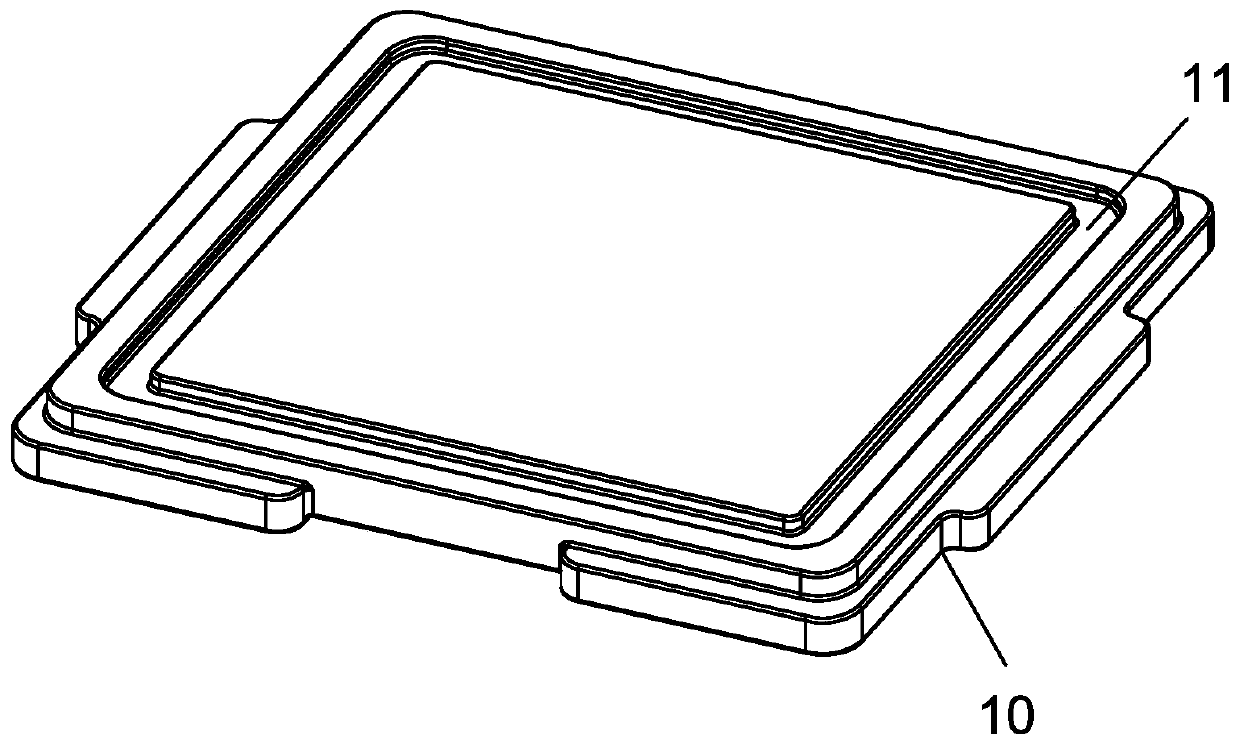

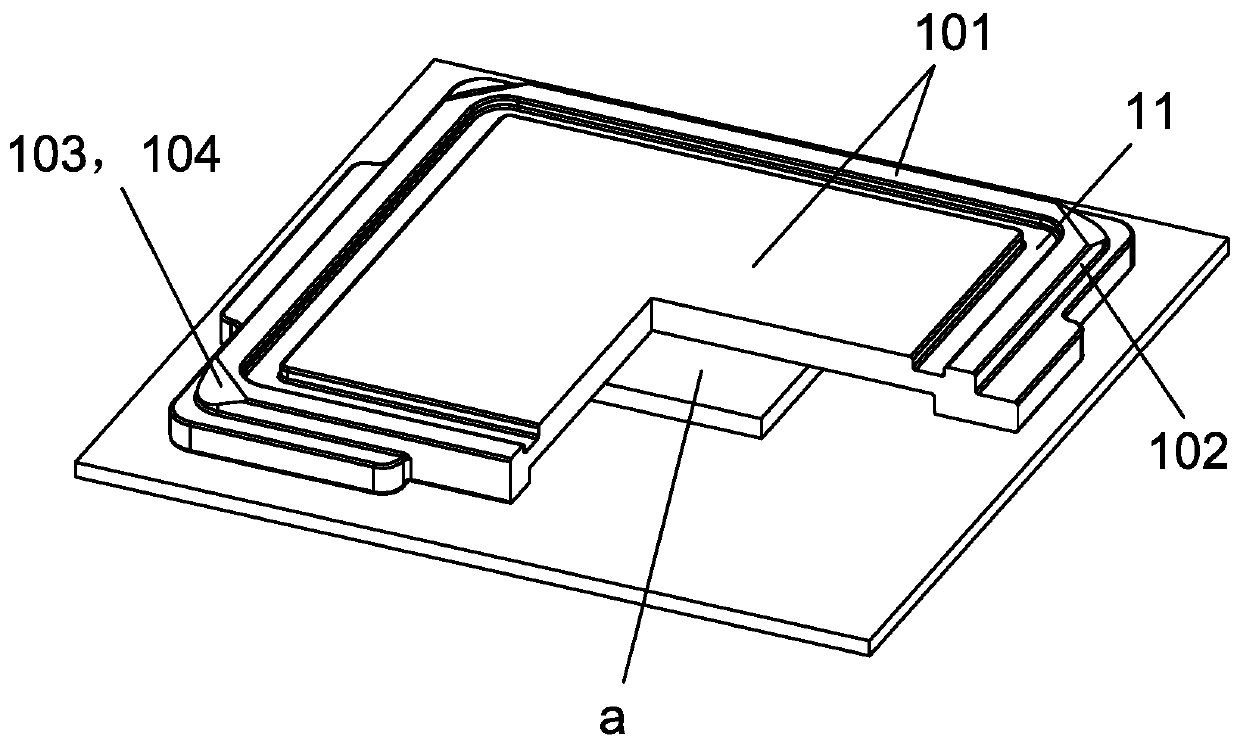

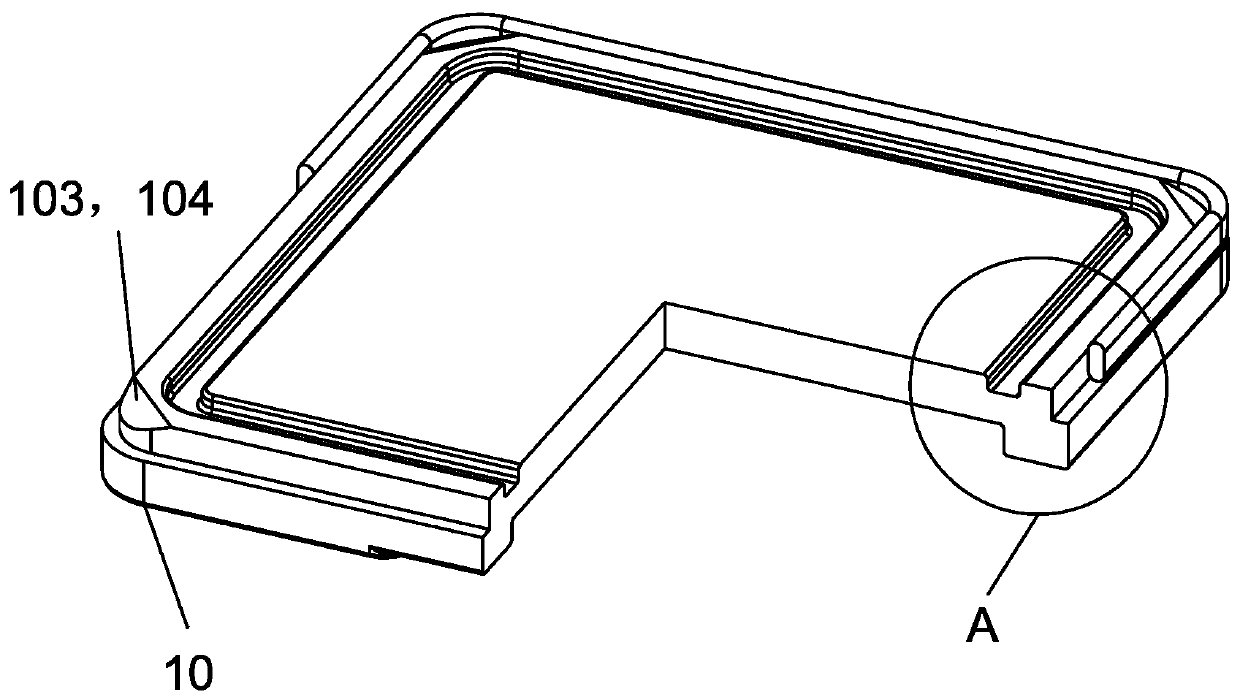

[0074] refer to Figures 1 to 5 , Figure 7 to Figure 9 ,Such as figure 1 and figure 2 The shown CPU top cover includes a cover body 10 , and a sunken groove 11 around the cover body 10 is provided on the top surface 101 of the cover body 10 in contact with the heat sink.

[0075] In the above structure, when the liquid gold is applied, the liquid gold is applied to the surface of the cover body 10 within the surrounding range of the sinking groove 11, and when the radiator is pressed on the surface of the cover body 10, the excess liquid gold will be squeezed into the Temporary storage in the sinking groove 11 can effectively prevent the liquid gold from being squeezed and flow to the outside of the cover 10, although the cover 10 with the sinking groove 11 is in contact with the cover 10 without the sinking groove 11. The area (heat conduction area) will be slightly reduced, but the contact area between chip a and cover 10 is only the size of a fingernail, and the fastes...

Embodiment 2

[0096] refer to Figures 1 to 5 , Figure 7 to Figure 9 ,Such as figure 1 and figure 2 The shown CPU top cover includes a cover body 10 , and a sunken groove 11 around the cover body 10 is provided on the top surface 101 of the cover body 10 in contact with the heat sink.

[0097] In the above structure, when the liquid gold is applied, the liquid gold is applied to the surface of the cover body 10 within the surrounding range of the sinking groove 11, and when the radiator is pressed on the surface of the cover body 10, the excess liquid gold will be squeezed into the Temporary storage in the sinking groove 11 can effectively prevent the liquid gold from being squeezed and flow to the outside of the cover 10, although the cover 10 with the sinking groove 11 is in contact with the cover 10 without the sinking groove 11. The area (heat conduction area) will be slightly reduced, but the contact area between chip a and cover 10 is only the size of a fingernail, and the fastes...

Embodiment 3

[0114] refer to figure 1 and figure 2 , Image 6 and Figure 10 ,Such as figure 1 and figure 2 , Image 6 and Figure 10 The shown CPU top cover includes a cover body 10 , and a sunken groove 11 around the cover body 10 is provided on the top surface 101 of the cover body 10 in contact with the heat sink.

[0115] In the above structure, when the liquid gold is applied, the liquid gold is applied to the surface of the cover body 10 within the surrounding range of the sinking groove 11, and when the radiator is pressed on the surface of the cover body 10, the excess liquid gold will be squeezed into the Temporary storage in the sinking groove 11 can effectively prevent the liquid gold from being squeezed and flow to the outside of the cover 10, although the cover 10 with the sinking groove 11 is in contact with the cover 10 without the sinking groove 11. The area (heat conduction area) will be slightly reduced, but the contact area between chip a and cover 10 is only t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com