MBR plate-type membrane cleaning agent and cleaning method

A technology for cleaning chemicals and plate membranes, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of unrecoverable chemicals, uneven chemical cleaning, etc., to save dosing time and stabilize water flow. The effect of low volume and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Taking the domestic sewage treated by a certain company as the raw water in this embodiment, the specific water quality data analysis is shown in Table 1:

[0070] Table 1

[0071] COD / ppm BOD / ppm Sludge concentration / ppm 2560 1480 4300

[0072] The above-mentioned sewage is treated by MBR plate membrane, and after 2-5 days of continuous operation, the cleaning agent and the online cleaning method of the present application are used for cleaning.

[0073] S1, preparation of alkaline cleaning agents, which includes the following components: sodium dodecylbenzenesulfonate 1wt%, sodium lauryl sulfate 0.5wt%, sodium hypochlorite 0.5wt% and MBR plate membrane treatment of the product water obtained, and use Sodium hydroxide adjusts the pH value to 10.5;

[0074] S2, stop the water production of the MBR plate membrane module, stop the aeration, and let stand for 10 minutes;

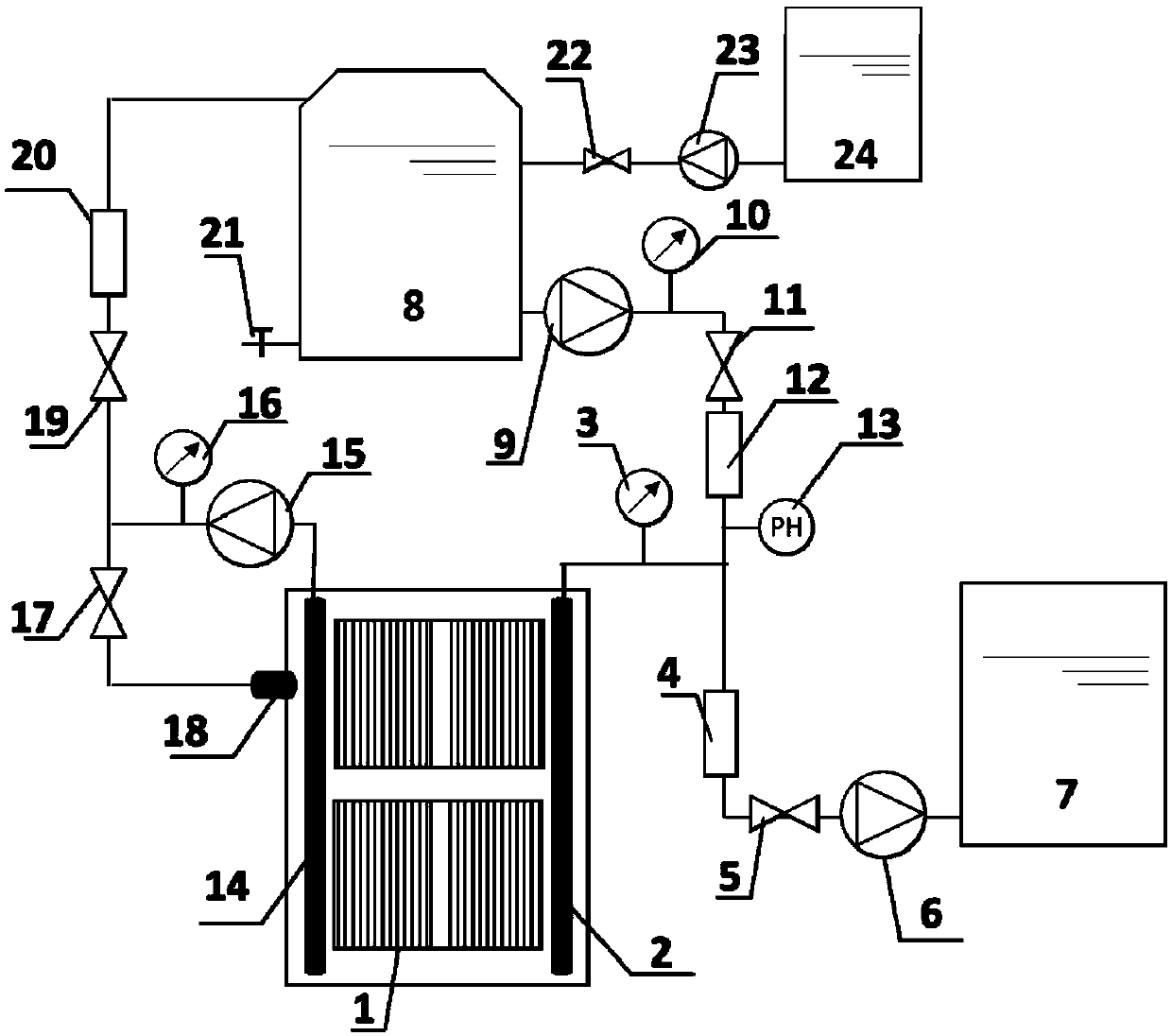

[0075] S3, open the dosing pipeline valve 11 and the membrane return tank ...

Embodiment 2

[0081] Taking Example 1 as the raw water of this embodiment, the above-mentioned sewage was treated with the MBR plate membrane, and after two months of continuous operation, the cleaning agent and the online cleaning method of the present application were used for cleaning.

[0082] S1, preparing an acid cleaning agent, which contains the following components: the content of activated carbon is 0.1wt%, the content of tetrasodium edetate is 2wt%; the content of sodium tripolyphosphate is 1wt%; the content of sodium sulfite is 1wt% , and the product water obtained by MBR plate membrane treatment, and adjust the pH value to 2 with citric acid;

[0083] S2, stop the water production of the MBR plate membrane module, stop the aeration, and let stand for 10 minutes;

[0084] S3, open the dosing pipeline valve 11 and the membrane return tank pipeline valve 17, open the cleaning agent dosing pump 9 and the cleaning agent return pump 15 to replace the water in the MBR plate membrane m...

Embodiment 3

[0090] Taking Example 1 as the raw water of this embodiment, the above-mentioned sewage was treated with MBR plate membrane, and after continuous operation for 6 months, the cleaning agent and online cleaning method of the present application were used for cleaning.

[0091] S1, preparation of alkaline cleaning agents, which includes the following components: 2wt% sodium dodecylbenzenesulfonate, 1wt% sodium dodecylsulfate, 2wt% sodium hypochlorite and the product water obtained by MBR plate membrane treatment, and oxidized with hydrogen Sodium adjusts the pH to 11;

[0092] S2, stop the water production of the MBR plate membrane module, stop the aeration, and let stand for 10 minutes;

[0093] S3, open the dosing pipeline valve 11 and the membrane return tank pipeline valve 17, open the cleaning agent dosing pump 9 and the cleaning agent return pump 15 to replace the water in the MBR plate membrane module, and stop the pump after 20 seconds;

[0094] S4, open the return water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com