Photocatalysis unit and photocatalysis method thereof

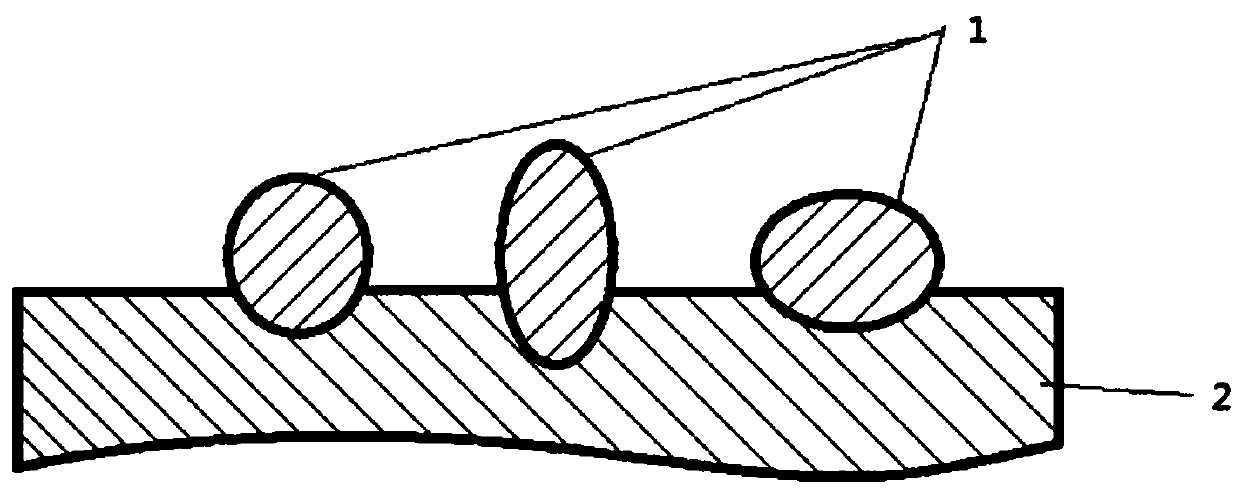

A photocatalytic unit and photocatalyst technology, applied in the field of photocatalysis, can solve problems such as difficult recycling, difficult separation, easy loss of titanium dioxide, etc., and achieve the effect of enhanced strength and large external specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] According to nano-titanium dioxide powder (particle size below 100nm, the same below): alumina dry rubber powder (calculated as alumina): peptizing acid: kaolin: water is mixed in a weight ratio of 1.5:10:2.5:0.4:6.0 to prepare Composite oxide precursor slurry A1;

[0073] Mix the nano-titanium dioxide powder with polyethylene glycol 600, then mix it with alumina dry rubber powder, peptizing acid, and water, according to nano-titanium dioxide powder: alumina dry rubber powder (calculated as alumina): peptizing acid: kaolin : water is mixed at a weight ratio of 3:10:2.5:0.3:6.5 to prepare composite oxide precursor slurry A2, wherein the amount of polyethylene glycol added accounts for 2% of the weight of the composite oxide precursor slurry;

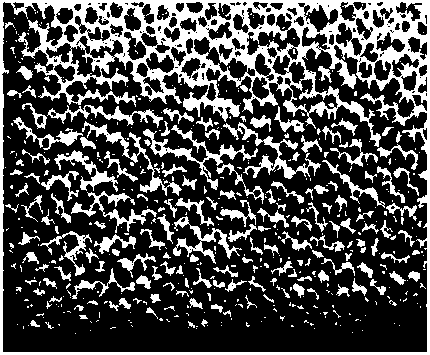

[0074] The foamed ceramics is 15cm long, 15cm wide, 1cm thick, with a porosity of 70%, a cell diameter of 1mm-5mm, and a pore density of 10ppi. The pore volume of the foamed ceramics is 0.31mL / g, the pore volume occupied by the po...

Embodiment 2

[0081] According to nano-titanium dioxide powder: alumina dry rubber powder (calculated as alumina): peptizing acid: kaolin: water is mixed in a weight ratio of 2.0:10:2.0:0.5:6.0 to prepare composite oxide precursor slurry B1;

[0082] Mix the nano-titanium dioxide powder with polyethylene glycol 600, then mix it with alumina dry rubber powder, peptizing acid, and water, according to nano-titanium dioxide powder: alumina dry rubber powder (calculated as alumina): peptizing acid: kaolin : The weight ratio of water is 2.5:10:2.5:0.3:6.5 and mixed to prepare the composite oxide precursor slurry B2, wherein the addition of polyethylene glycol accounts for 2% of the weight of the composite oxide precursor slurry;

[0083] Take a square ceramic foam with a length of 15 cm, a width of 15 cm, a thickness of 1 cm, a porosity of 70%, a cell diameter of 1 mm to 5 mm, and a pore density of 20 ppi. The pore volume of the foamed ceramics is 0.26mL / g, the pore volume occupied by the pore di...

Embodiment 3

[0089] The composite oxide precursor slurry C1 was prepared by mixing nano titanium dioxide powder: alumina dry rubber powder (calculated as alumina): peptizing acid: kaolin: water at a weight ratio of 1.0:10:2.0:0.5:6.0.

[0090] Mix the nano-titanium dioxide powder with polyethylene glycol 600, then mix it with alumina dry rubber powder, peptizing acid, and water, according to nano-titanium dioxide powder: alumina dry rubber powder (calculated as alumina): peptizing acid: kaolin : water is mixed at a weight ratio of 3.0:10:3.0:0.3:8.0 to prepare composite oxide precursor slurry C2, wherein the addition of polyethylene glycol accounts for 2.5% of the weight of the composite oxide precursor slurry;

[0091] Get ceramic foam with embodiment 1. Vacuum impregnate the foamed ceramics with composite oxide precursor slurry C1 twice, then dry at 70°C for 6 hours after impregnation, then vacuum impregnate composite oxide precursor slurry C2, and then dry at 70°C for 6 hours. Two-stag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com