Red and green light perovskite quantum dot stable fluorescent powder based on SiO2 coating and preparation

A technology of silicon dioxide and quantum dots, applied in nanotechnology, nano-optics, luminescent materials, etc. for materials and surface science, can solve problems affecting luminous efficiency and purity, deterioration and agglomeration, poor stability, etc., to achieve suitable Effects of fluorescence lifetime, improved stability, and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

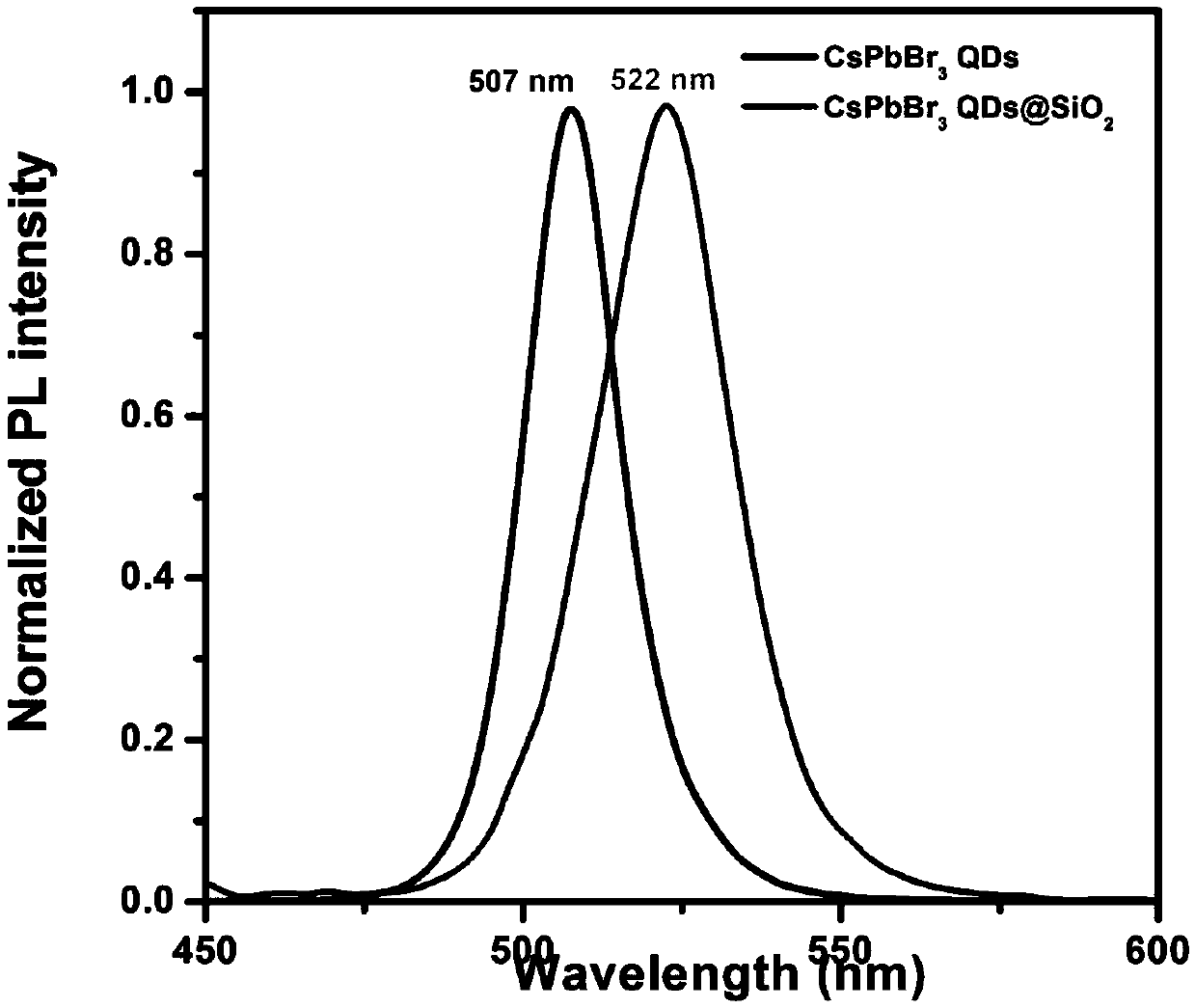

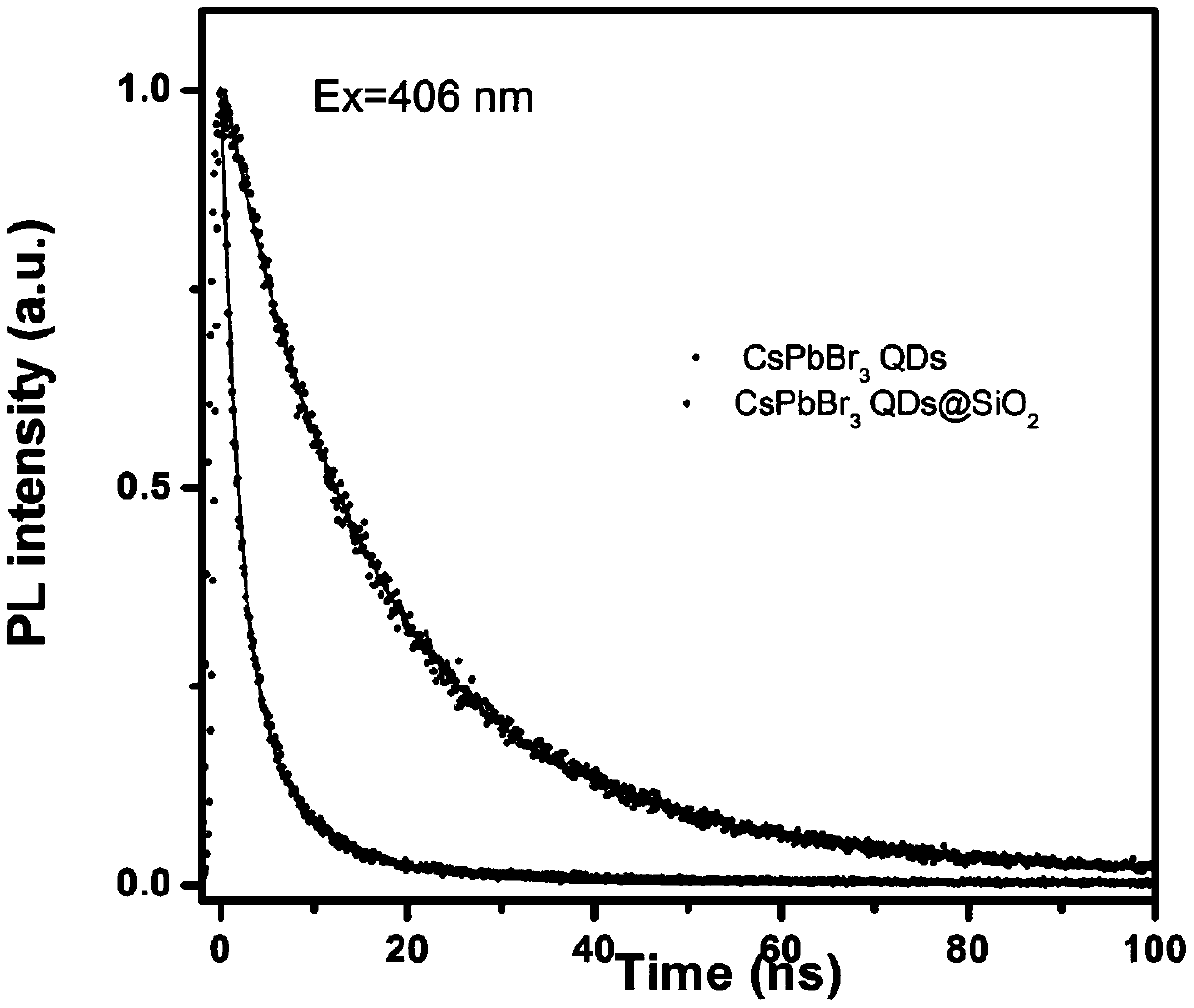

[0035] A preparation process based on silicon dioxide-coated green light perovskite quantum dot stabilized phosphor, specifically comprising the following steps:

[0036] (1) Accurately weigh 0.407 g of cesium carbonate, 1.5 mL of oleic acid, and 20 mL of octadecene into a two-neck round bottom flask. Heat to 130°C under vacuum and keep for 1h. Then the temperature was lowered to 100°C, and nitrogen gas was introduced.

[0037] (2) Accurately weigh PbBr 2 0.276g, measure 20mL of octadecene, 2mL of oleic acid, and 2mL of oleylamine, add it to a 100mL three-neck round bottom flask, heat to 120°C under vacuum, and keep for 1h. Nitrogen gas was then introduced, and the temperature was rapidly raised to 180°C.

[0038] (3) Draw 1.6mL of cesium oleate precursor solution into PbBr quickly with a syringe 2 After 5 s in the precursor solution, it was quickly cooled to room temperature in an ice-water bath.

[0039] (4) Centrifuge the above-mentioned liquid product at 5000rpm to t...

Embodiment 2

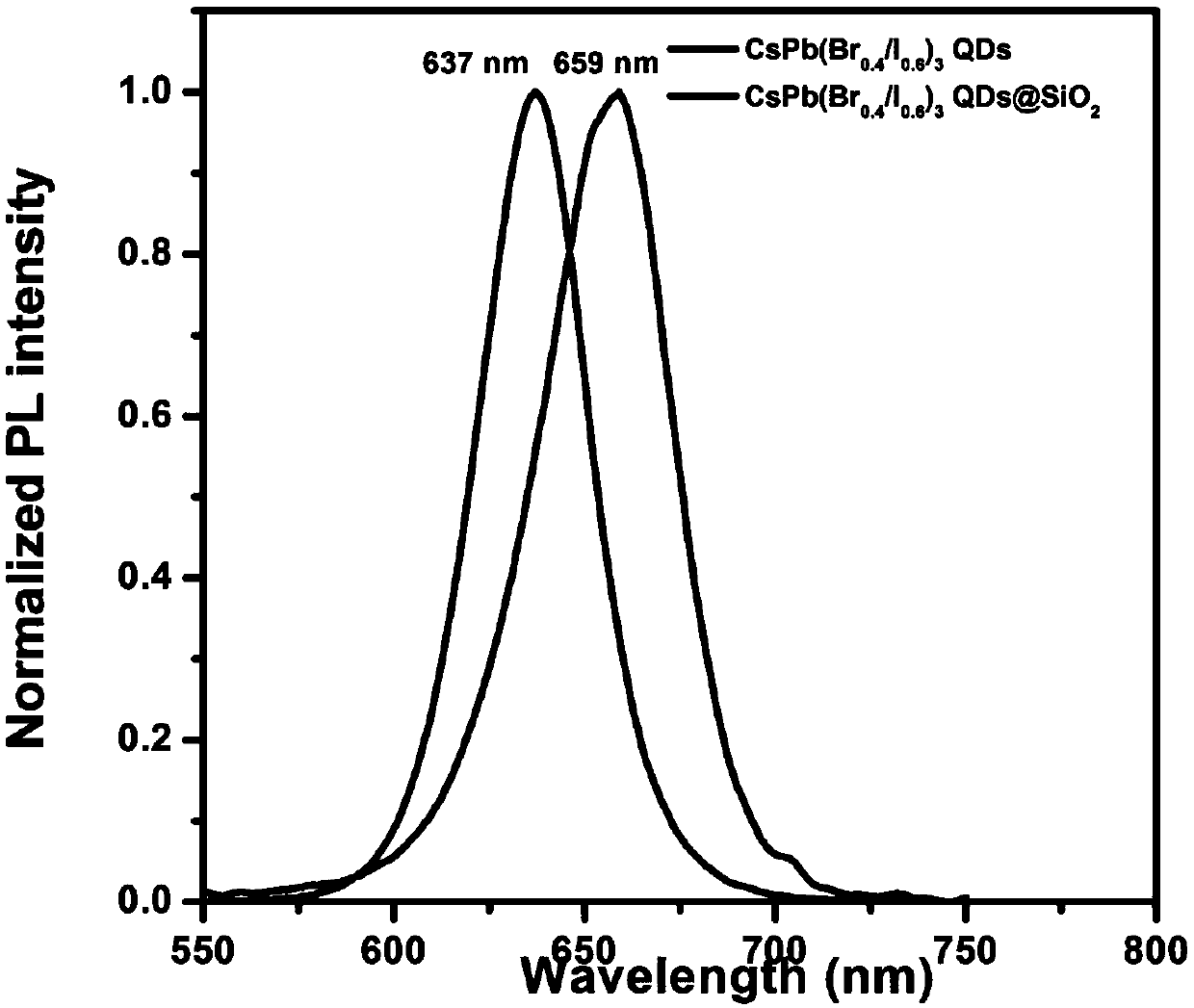

[0045] A preparation process based on silica-coated red light perovskite quantum dot stabilized phosphor, specifically comprising the following steps:

[0046] (1) Accurately weigh 0.407 g of cesium carbonate, 1.5 mL of oleic acid, and 20 mL of octadecene into a two-neck round bottom flask. Heat to 130°C under vacuum and keep for 1h. Then the temperature was lowered to 100°C, and nitrogen gas was introduced.

[0047] (2) Accurately weigh PbBr 2 0.1104g, PbI 2 0.208g, measure 20mL of octadecene, 2mL of oleic acid, and 2mL of oleylamine, add it into a 100mL three-neck round bottom flask, heat to 120°C under vacuum, and keep for 1h. Nitrogen gas was then introduced, and the temperature was rapidly raised to 180°C.

[0048] (3) Draw 1.6mL of cesium oleate precursor solution into PbBr quickly with a syringe 2 After 5 s in the precursor solution, it was quickly cooled to room temperature in an ice-water bath.

[0049] (4) Centrifuge the above-mentioned liquid product at 5000rp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com