Vitamin K1 injection and preparation method thereof

A technology for vitamins and injections, applied in anti-inflammatory agents, pharmaceutical formulas, non-central analgesics, etc., can solve the problems of poor stability, easy decomposition, and darkening of vitamin K1, and is suitable for industrial scale-up production, improving solubility, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Example 1 Preparation of Vitamin K1 Mixed Micelle Solution and Injection

[0068] The specification of the injection to be prepared in this example is 1mL / bottle, each containing 10mg of the main drug vitamin K1, calculated on the basis of 1000 injections, the composition is as follows:

[0069]

[0070] The specific operation process is as follows:

[0071] (1) Weigh each component according to the stated ratio, put it in a beaker, add an appropriate amount of ethanol, put it in a water bath magnetic stirrer, heat to 40°C ± 2°C, stir, and dissolve until clear;

[0072] (2) heat the solution obtained in step (1) at 40°C ± 2°C, keep it away from light, pass nitrogen gas for 1-2 hours, and volatilize to remove ethanol to obtain a semi-solid mixture;

[0073] (3) Add 80% of the prescribed amount of water for injection to the semi-solid mixture obtained in step (2), adjust the pH to 5.4, continue to stir until clarified, make up the amount of water for injection to the ...

Embodiment 2

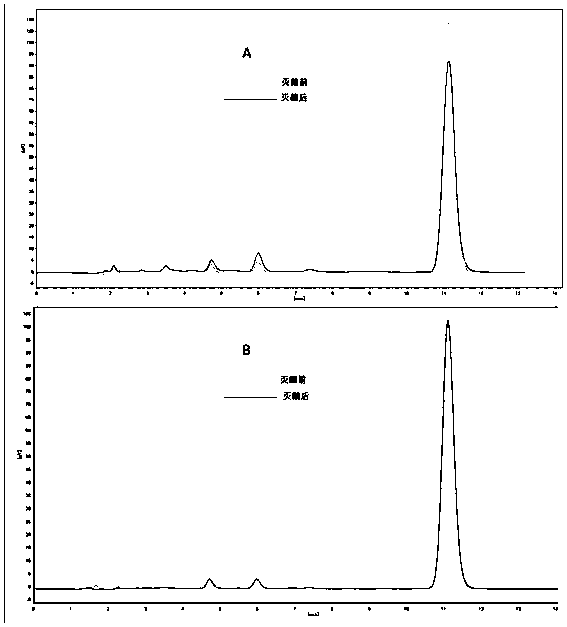

[0075] The physicochemical property test of embodiment 2 micelle solution

[0076] (1) Particle size and Zeta potential measurement

[0077] The solution containing vitamin K1 mixed micelles prepared in Example 1 was diluted to 0.5 mg / mL, and the average particle size of the micelles was measured by MalvernNano ZS90 Zetasizer, and the average particle size of the micelles was 9.7±2.0 nm.

[0078] (2) Morphological investigation

[0079] The diluted mixed micelle solution was added dropwise to the copper grid, counterstained with 2% sodium phosphotungstate solution, observed and photographed under a transmission electron microscope (TEM). The prepared mixed micelles are evenly distributed quasi-spherical entities (such as Figure 7 shown).

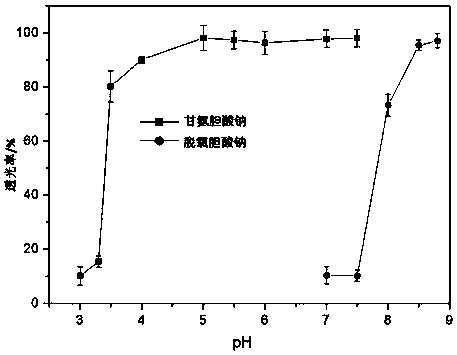

[0080] (3) Solution light transmittance test

[0081] Take the mixed micelle solution, and measure its light transmittance (%) at 600 nm by using a UV-visible spectrophotometer. The light transmittance of the solution was measured to b...

Embodiment 3

[0090] The 2-year stability study of embodiment 3 injection

[0091] The sterilized injection was prepared according to the method of Example 1, and a 2-year stability study was carried out, and the results are shown in Table 1.

[0092] Table 1 Stability data of vitamin K1 phospholipid / bile salt mixed micelles sterilized injection

[0093]

[0094] As can be seen from Table 1, the injection solution of the present invention has good stability, and the storage period can reach more than 2 years.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com