Efficient spray full-coverage rotational flow spray desulfurization tower and desulfurization system

A desulfurization system and full-coverage technology, applied in the field of flue gas desulfurization treatment, can solve problems such as unbalanced equipment development, affecting the economic and environmental benefits of enterprises, and unstable operation, so as to improve the desulfurization treatment effect, prolong the full contact time, Good defogging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

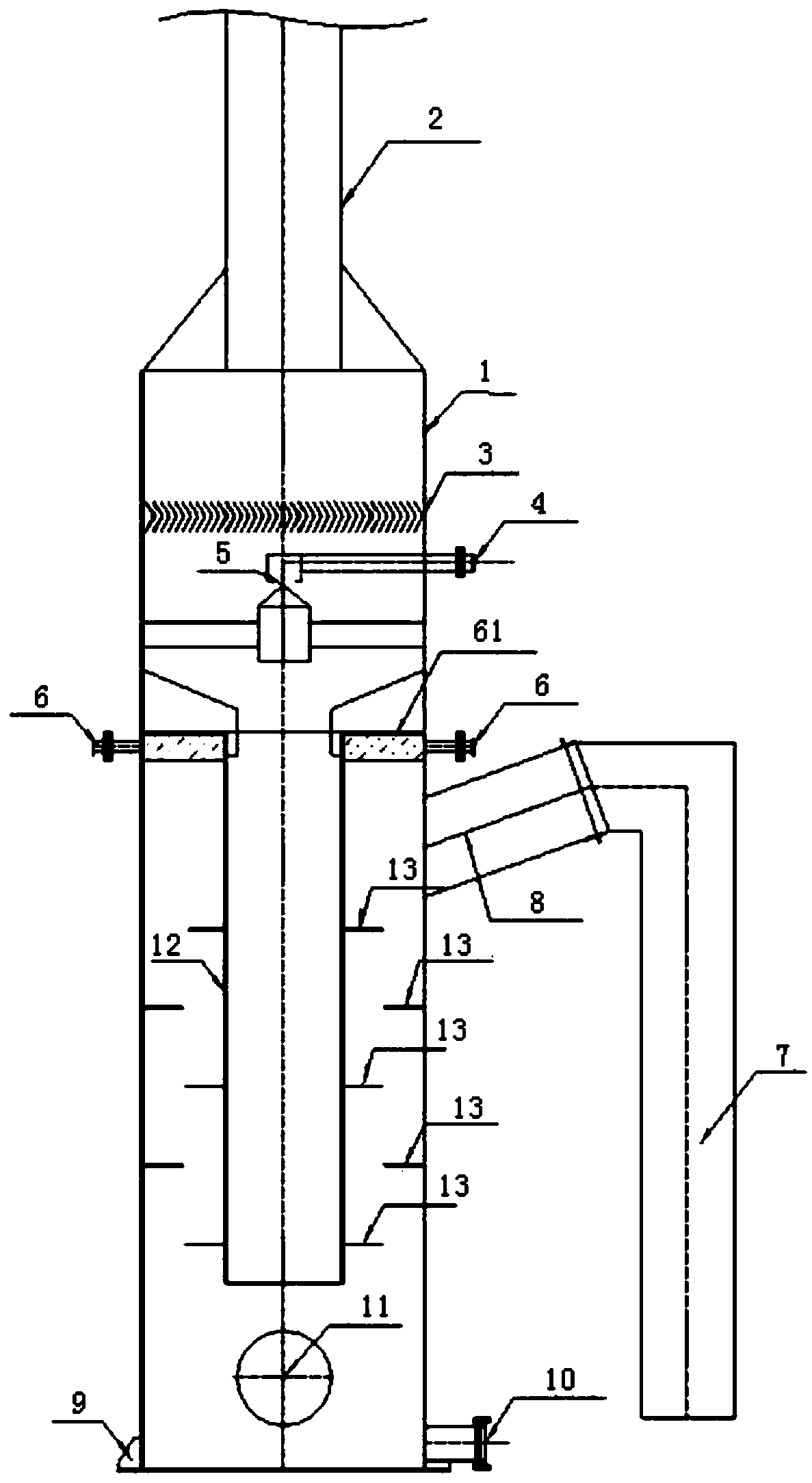

[0023] A high-efficiency spray full-coverage swirl spray desulfurization tower, including: tower body 1, first liquid inlet 4, first liquid distributor 5, second liquid inlet 6, second liquid distributor 61, flue gas inlet 8. Bile duct 12, baffle plate 13, base 9, return water outlet 10, flue gas outlet 2, demister 3;

[0024] The tower body 1 and the bile duct 12 are cylindrical structures; the bile duct 12 is inside the tower body 1 and coaxial with the tower body 1; the bile duct 12 is not in contact with the bottom of the tower body 1; The baffles 13 are annular, interlaced and fixed between the tower body 1 and the bile duct 12;

[0025] The first water inlet 4 and the first liquid distributor 5 are installed above the bile duct 12; the second liquid inlet 6 and the second liquid distributor 61 are arranged in a circular shape between the tower body 1 and the bile duct 12 above the space;

[0026] The flue gas inlet 8 is installed on the side of the tower body 1, below ...

Embodiment 2

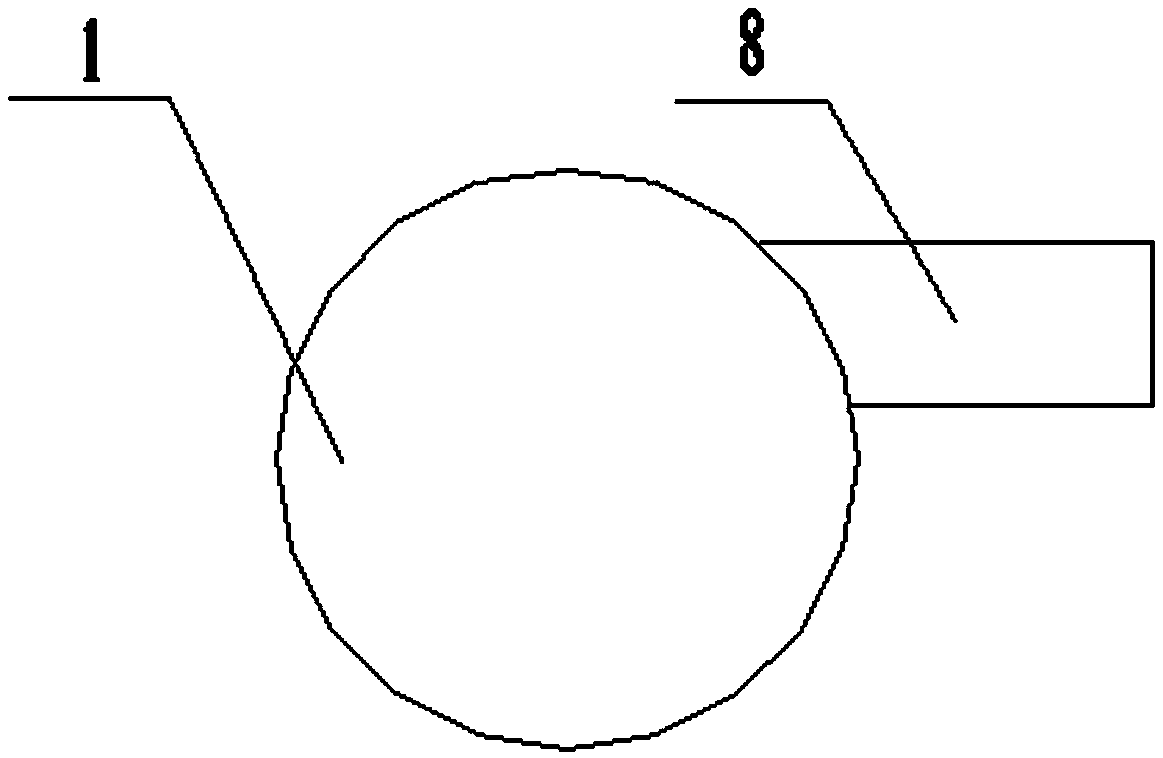

[0036] The difference from Embodiment 1 is that the flue gas inlet 8 is arranged eccentrically relative to the tower body 1 . This makes the flue gas generate swirling flow in the tower body 1, further improving the desulfurization effect of the flue gas.

Embodiment 3

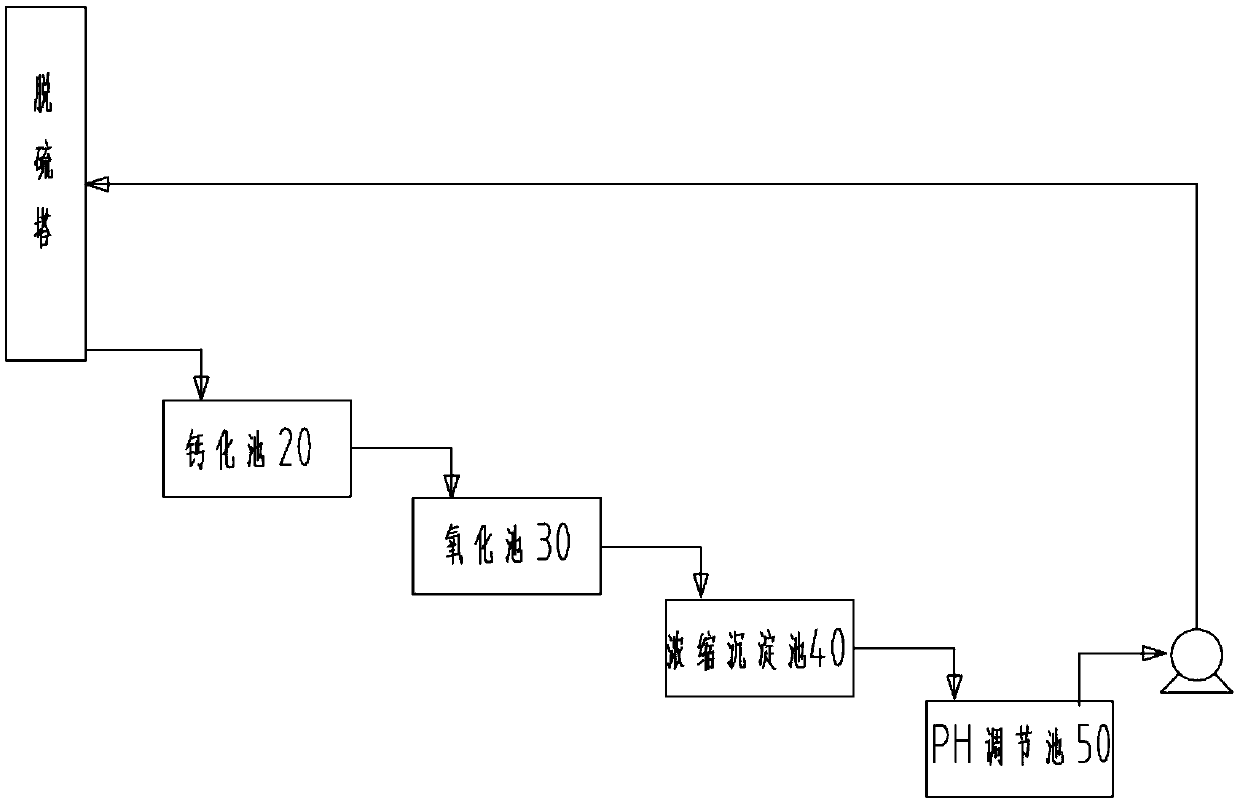

[0038] A desulfurization system, comprising the high-efficiency spray full-coverage swirl spray desulfurization tower in claims 1-9, the calcification pool 20, the oxidation pool 30, the concentrated sedimentation pool 40, and the pH adjustment pool 50; the high-efficiency spray full-coverage swirl The treatment liquid in the flow spray desulfurization tower flows through the return water outlet 10, the calcification tank 20, the oxidation tank 30, the concentration sedimentation tank 40, and the pH adjustment tank 50 in sequence, and then is pumped to the first liquid inlet 4 and the second inlet Liquid port 6.

[0039] The oxidation pond 30 includes an air aeration system.

[0040] The treatment liquid used in the system is sodium hydroxide solution, which absorbs sulfur dioxide in the desulfurization tower to generate sodium sulfite and sodium bisulfite. Afterwards, the treatment liquid containing sodium sulfite and sodium bisulfite enters the calcification tank 20 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com