A detection method for comparison test of formaldehyde emission by dryer method

A technology of formaldehyde emission and detection method, which is applied in the detection field of formaldehyde emission comparison test by dryer method, can solve the problems of poor timeliness, high cost, poor uniformity and stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] A detection method for the comparison test of formaldehyde emission in a dryer method, comprising:

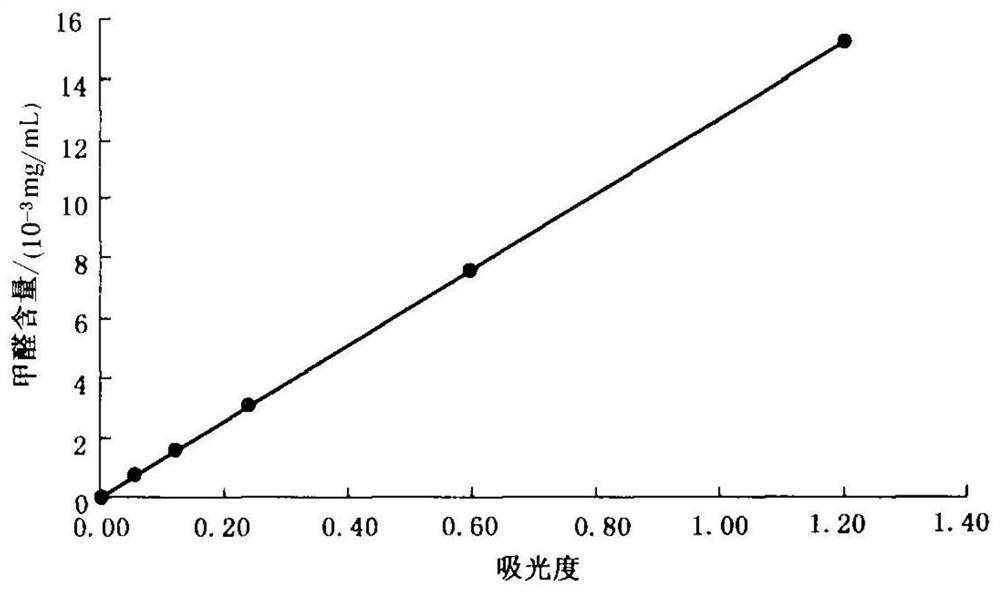

[0067] Step 1: Standard Curve Drawing

[0068] 11) Formaldehyde solution calibration;

[0069] Transfer 1mL of formaldehyde solution with a concentration of 35-40% to a 1000mL volumetric flask, and dilute to the mark with distilled water; then measure 20mL of formaldehyde solution, 25mL of 0.05mol / L iodine standard solution, 10mL of 1mol / L hydroxide Sodium standard solution was mixed in a 100mL Erlenmeyer flask with a stopper; after standing in a dark place for 15min, 15mL of 1mol / L sulfuric acid solution was added to the mixture; excess iodine was titrated with 0.1mol / L sodium thiosulfate solution, and the titration approached the end point Add a few drops of 1% starch indicator and continue the titration until the solution becomes colorless; at the same time, use 20mL distilled water to do a blank parallel test;

[0070] The mass concentration of formaldehyde solutio...

Embodiment 2

[0130] A kind of desiccator method formaldehyde emission comparative test detection method: standard curve drawing, with embodiment 1;

[0131] Determination of the background concentration of the box is 0.005mg / m 3 , in line with the background concentration ≤ 0.006mg / m 3 the test conditions.

[0132] Take 1.25mL of analytically pure formaldehyde solution with a concentration of 37%, and dilute it to 750mL as a customized formaldehyde solution (concentration of formaldehyde solution is 0.6167‰).

[0133] Take 30ml of custom-made formaldehyde solution and pour it into a 100mL beaker (beaker diameter 59mm), place the beaker in the center of the wire support net in time (within 5min), and close the desiccator.

[0134] The test method is the same as in Example 1.

[0135] Repeated experiments of the same sample in 3 different laboratories, numbered No. 1, No. 2, and No. 3, respectively. Table 7-9 shows the measurement results of No. 1-3 formaldehyde custom-made solutions by t...

Embodiment 3

[0150] A kind of desiccator method formaldehyde emission comparative test detection method: standard curve drawing, with embodiment 1;

[0151] Determination of the background concentration of the box is 0.004mg / m 3 , in line with the background concentration ≤ 0.006mg / m 3 the test conditions.

[0152] Take 1.25mL of analytically pure formaldehyde solution with a concentration of 37%, and dilute it to 1000mL as a customized formaldehyde solution (the concentration of formaldehyde solution is 0.4625‰).

[0153] Take 30ml of custom-made formaldehyde solution and pour it into a 100mL beaker (beaker diameter 59mm), place the beaker in the center of the wire support net in time (within 5min), and close the desiccator.

[0154] The test method is the same as in Example 1.

[0155] Repeated experiments of the same sample in 3 different laboratories, numbered No. 1, No. 2, and No. 3, respectively. Table 11-13 shows the measurement results of No. 1-3 formaldehyde custom-made solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com