Method for efficient, continuous and selective separation of carbon nanotubes in gas phase

A carbon nanotube and selective technology, applied in the direction of carbon nanotubes, nanocarbon, chemical instruments and methods, etc., can solve the problems of high cost, difficulty in separating metal-type and semiconductor-type carbon nanotubes, and achieve fewer implementation steps , continuous operability, and cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The method for the gas phase efficient continuous selective separation of carbon nanotubes in this embodiment comprises the following steps:

[0022] Step 1: Preparation of SWCNTs by HiPco method, using CO as carbon source, Fe(CO) 5 As a catalyst, the mixture of carbon source and catalyst is passed into a tube furnace with a temperature of 1000 degrees Celsius, the pressure in the furnace is controlled at 30-50 atm, and the insulation reaction is 1 hour to prepare SWCNTs with a purity of 97%. Take 15g of SWCNTs and 15g of Sodium lauryl sulfate is mixed in the aqueous solution, ultrasonically dispersed, filtered, washed with ethanol, and dried at 100 degrees Celsius for use;

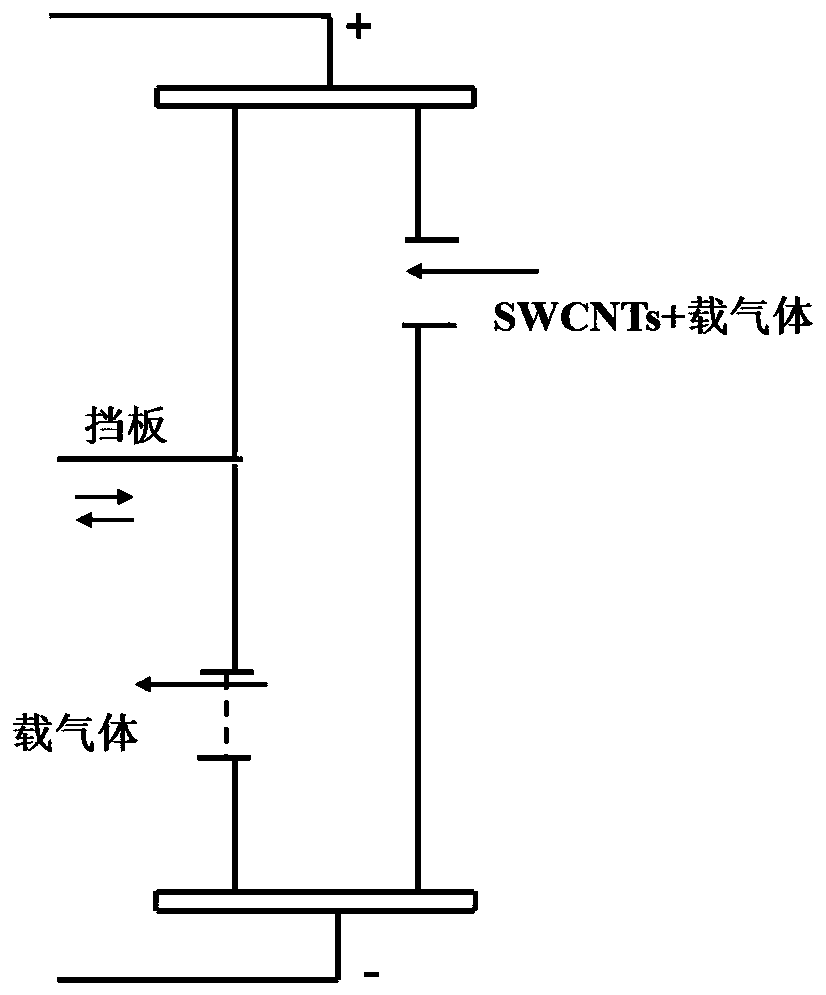

[0023] Step 2: mix the mixed gas of argon and trimethylamine with the well-dispersed SWCNTs from figure 1 The inlet end of the SWCNTs gas phase separation device shown is sent into the container, fully mixed under the action of gas stirring, so that the adsorption of metal-type SWCNTs to amine rea...

Embodiment 2

[0026] The method for the gas phase efficient continuous selective separation of carbon nanotubes in this embodiment comprises the following steps:

[0027] Step 1: Using dichlorobenzene as the carbon source and ferrocene as the catalyst, SWCNTs are prepared by chemical vapor deposition, using argon to discharge the residual air in the furnace and then introducing hydrogen, wherein the amount of argon is 800 Sccm and the amount of hydrogen is 2000 Sccm; The dichlorobenzene solution with ferrocene enters the furnace tube through the carrier gas, and reacts at 1100 degrees Celsius to obtain SWCNTs; take 30g of SWCNTs and 35g of sodium cholate and mix them in the aqueous solution, ultrasonically disperse evenly, filter, and wash with ethanol , dried at 100 degrees Celsius for later use;

[0028] Step 2: Mix the mixed gas of nitrogen and isopropylamine vapor with the well-dispersed SWCNTs from figure 1 The inlet end of the SWCNTs gas phase separation device shown is sent into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com