A kind of macro preparation method of porous graphene oxide

A technology of graphene and stone oxide, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the unfavorable mass production of porous graphene oxide, and achieve low cost, few implementation steps, and uniform composition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The macro preparation method of porous graphene oxide of the present invention comprises the following steps:

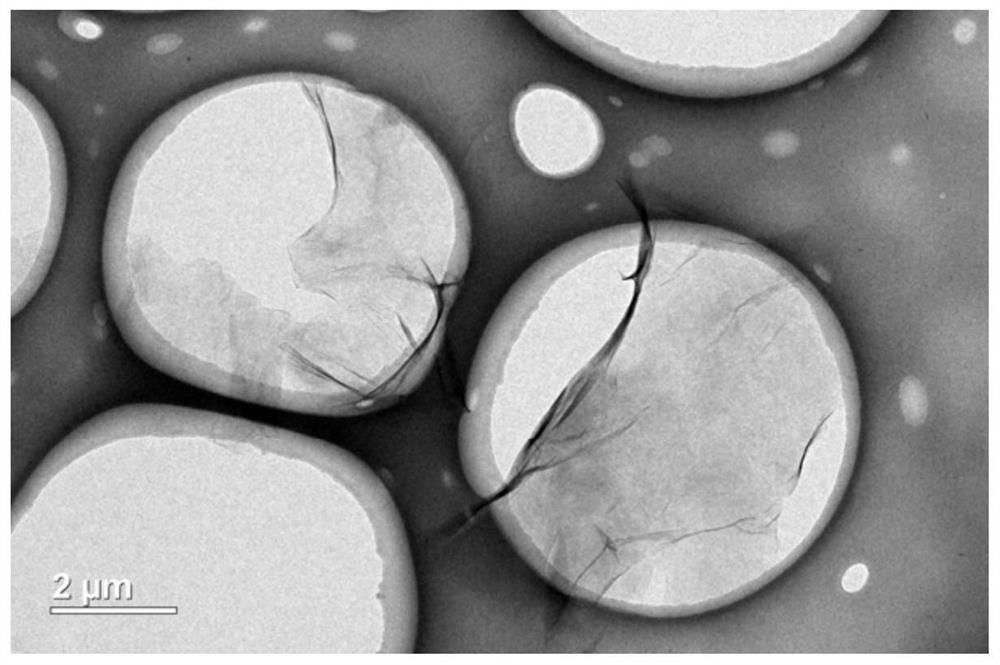

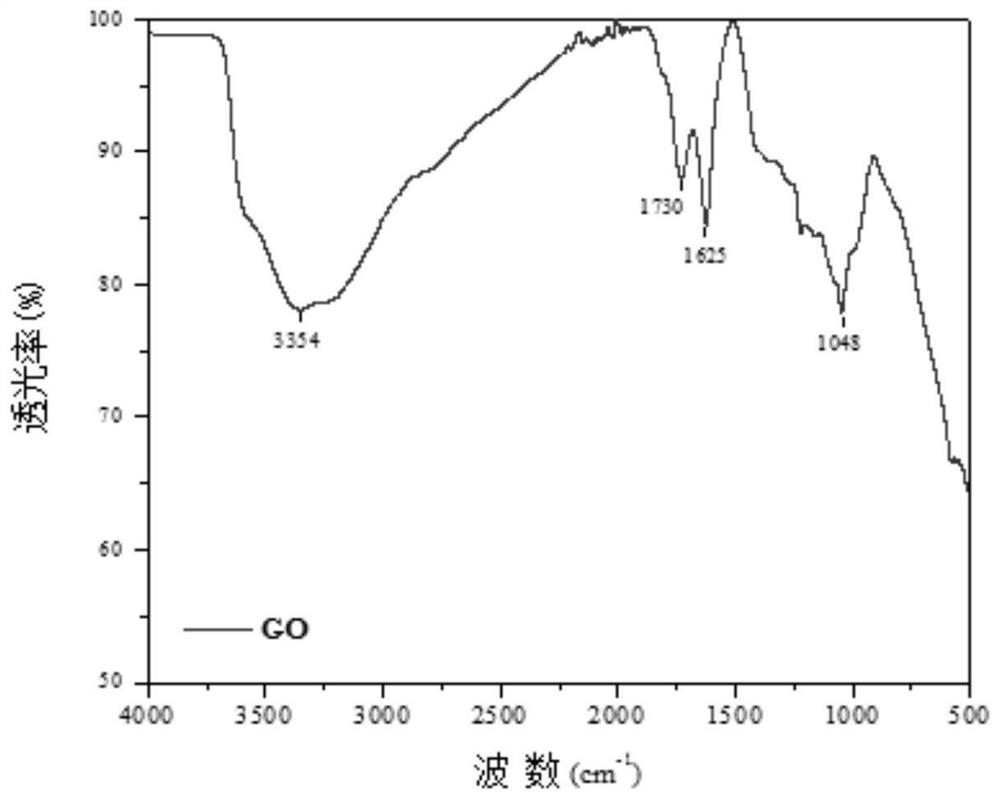

[0055] 1) Using graphite as a raw material, graphene oxide is prepared by the Hummers improved method, and the graphene oxide prepared is prepared into a graphene oxide aqueous solution;

[0056] 2) ultrasonically dispersing the graphene oxide aqueous solution prepared in step 1), to obtain a uniformly dispersed graphene oxide aqueous solution;

[0057] 3) Slowly pour the cryogenic liquid into the uniformly dispersed graphene oxide aqueous solution prepared in step 2) to obtain graphene oxide ice cubes;

[0058] 4) Freeze-drying the graphene oxide ice cubes obtained in step 3) to obtain the porous graphene oxide.

Embodiment 1

[0060] The preparation of graphene oxide starts with H 2 SO 4 and H 3 PO 4 Mix the acid solutions in a 9:1 volume ratio configuration. Take 1g of flake graphite and 100mL of mixed acid solution and mix them in a single-necked flask, and stir them with magnetic force at room temperature to make them evenly mixed. Place the single-necked flask with the mixed solution under an ice-water bath, and slowly add an appropriate amount of potassium permanganate therein, and react with magnetic stirring for 1 h. After the reaction was completed, the one-necked flask was placed in a medium-temperature constant-temperature water bath and stirred for a certain period of time. After cooling to room temperature, it was poured into 100 mL of ice water, stirred evenly, and then hydrogen peroxide was added drop by drop until the solution turned bright yellow. After the reaction, the reaction product was centrifuged and washed with dilute hydrochloric acid, ethanol, and water, respectively, ...

Embodiment 2

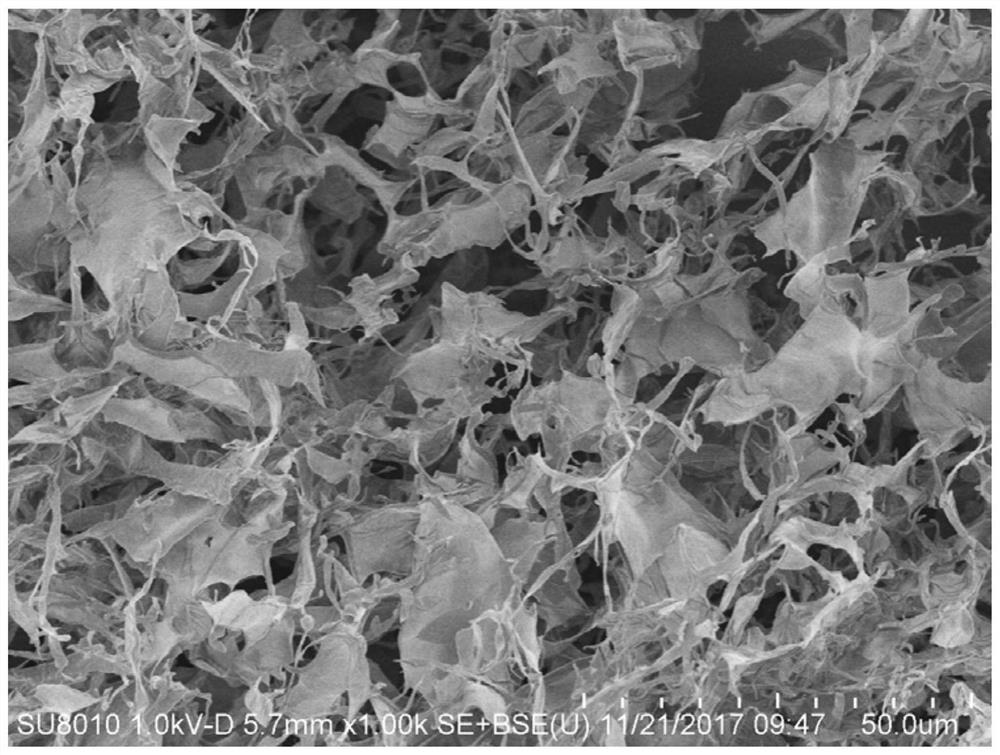

[0064] Take 0.002 g of graphene oxide, prepare 2 mL of graphene oxide aqueous solution with a concentration of 1 mg / mL, and sonicate at a frequency of 20 kHz for 150 min to obtain a uniformly dispersed graphene oxide solution. Then, the normal temperature gaseous liquid nitrogen is slowly poured into the graphene oxide solution at a rate of 30mL / min until the solution is completely frozen into ice cubes, and then freeze-dried at -40°C for 24 hours to obtain the graphene oxide solution with micron Porous graphene oxide. The scanning electron microscope picture of the porous graphene oxide prepared by the present embodiment is as follows image 3 shown by image 3 It can be seen that the pore size of the porous graphene oxide prepared in this example is about 10 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com