Method for preparing carbon/nickel composite wave-absorbing material with macroporous structure by gamma-ray irradiation method

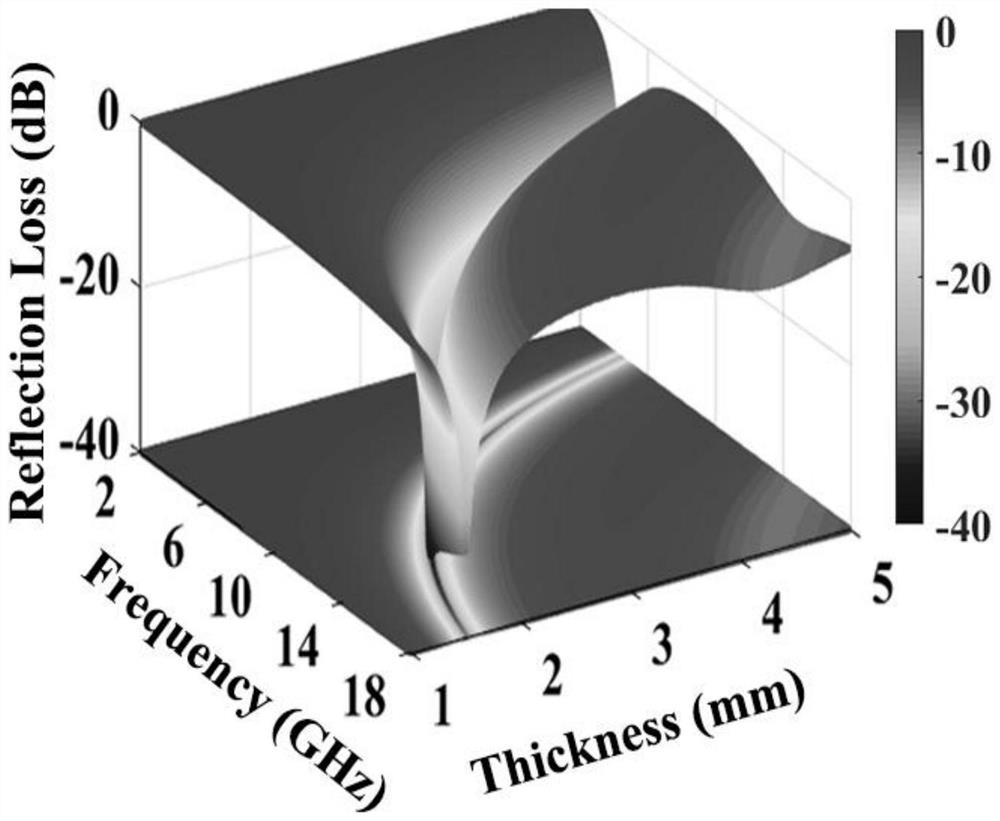

A composite wave-absorbing material and ray irradiation technology, which is applied in the preparation/purification of carbon, magnetic/electric field shielding, electrical components, etc., can solve the problems of small influence and poor electromagnetic wave absorption performance, and achieve low pollution and environmental hazards , Increase the effect of impedance matching characteristics and multiple reflection capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

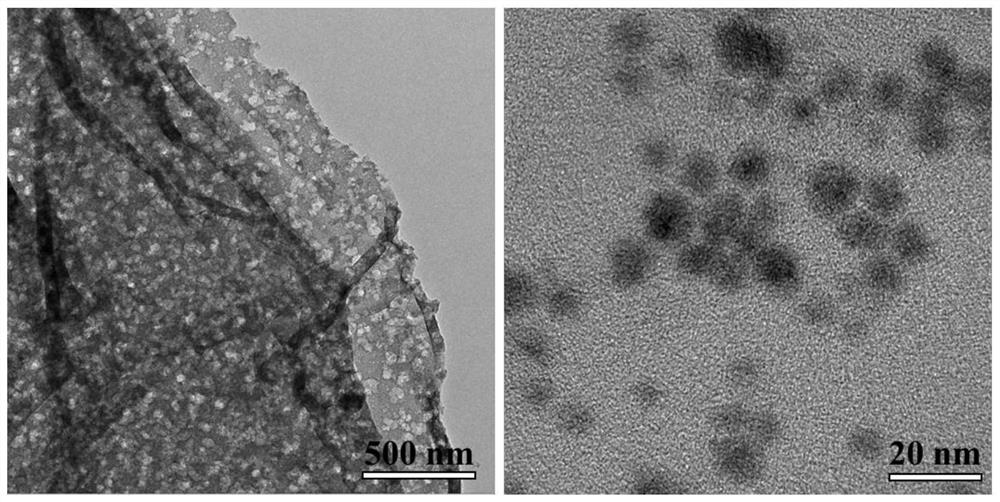

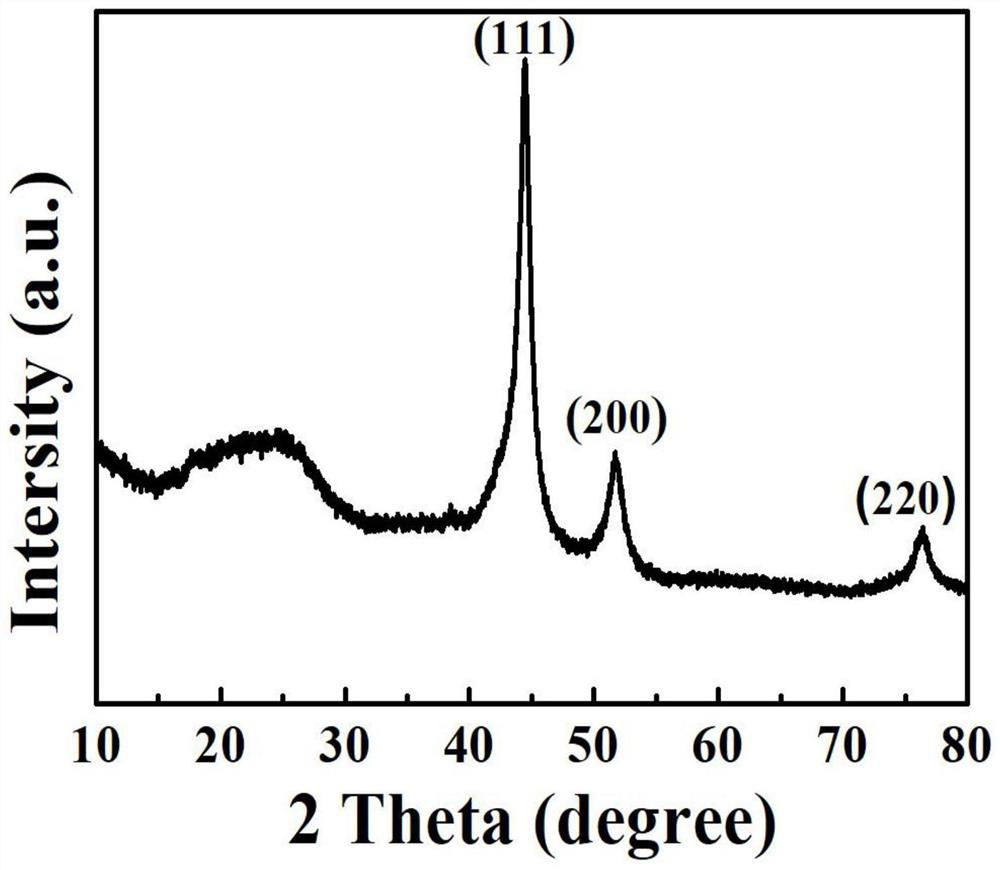

[0035] Embodiment 1: A method of preparing a carbon / nickel composite wave-absorbing material with a macroporous structure in this embodiment is carried out according to the following steps:

[0036] 1. Peel off the outer skin of the mature corn stalks, cut the corn stalks into pieces, wash with deionized water, filter, dry in a blast drying oven at 80°C for 3 hours, and then place them in 0.5mol / L acetic acid Immerse in nickel solution for 2 hours, filter, and dry in a blast drying oven at 80°C for 3 hours to obtain straw pulp;

[0037] 2. Place the dried straw pulp in step 1 in a ceramic boat and perform high-temperature carbonization and pyrolysis under a nitrogen atmosphere. The specific process of the high-temperature carbonization and pyrolysis is: the temperature is raised from room temperature to 750°C at a heating rate of 5°C / min, And heat preservation at this temperature for 2 hours to obtain carbonized material;

[0038] 3. The carbonized material obtained in step 2...

Embodiment 2

[0041] Embodiment 2: the difference between this embodiment and embodiment 1 is: the concentration of nickel acetate described in step 1 is 0.05mol / L. Other steps and parameters are the same as in Example 1.

Embodiment 3

[0042] Embodiment 3: the difference between this embodiment and embodiment 1 is: the concentration of nickel acetate described in step 1 is 0.25mol / L. Other steps and parameters are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com