Preparation method of polyether polyol having function of improving hardness and strength of soles

A polyether polyol, strength technology, applied in the field of polyether polyol preparation, can solve the problems of reducing the hardness and strength of shoe soles, achieve the effect of improving hardness and strength, and improving comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

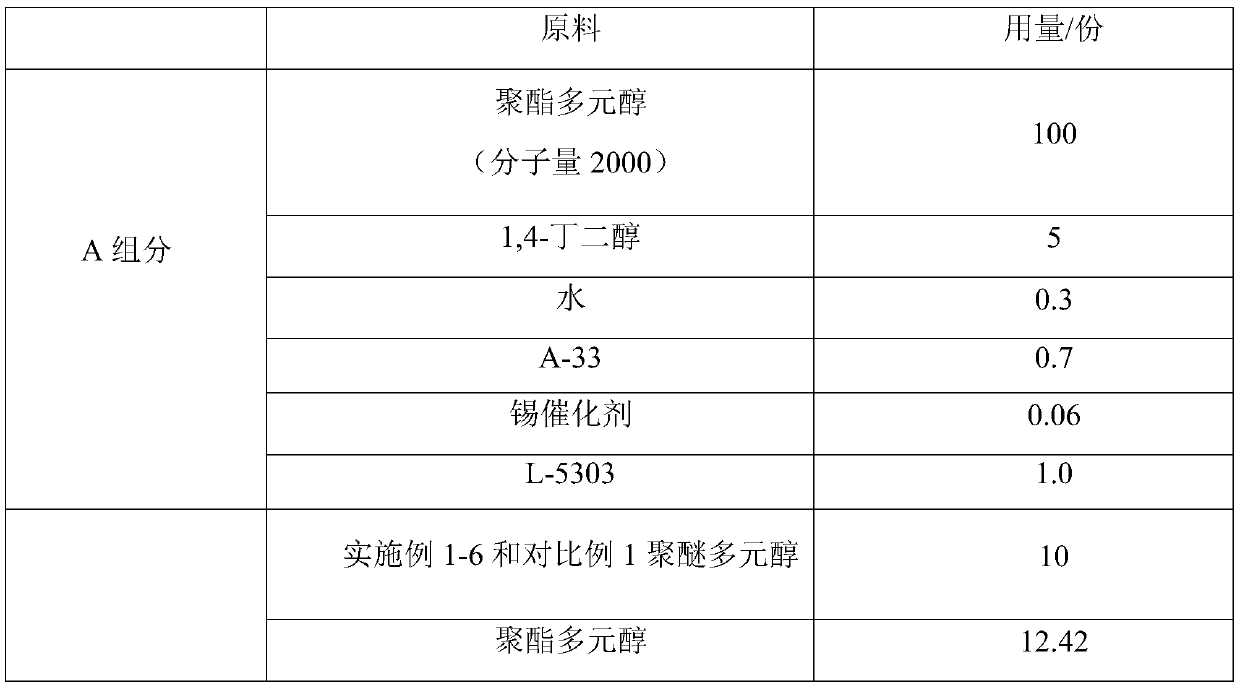

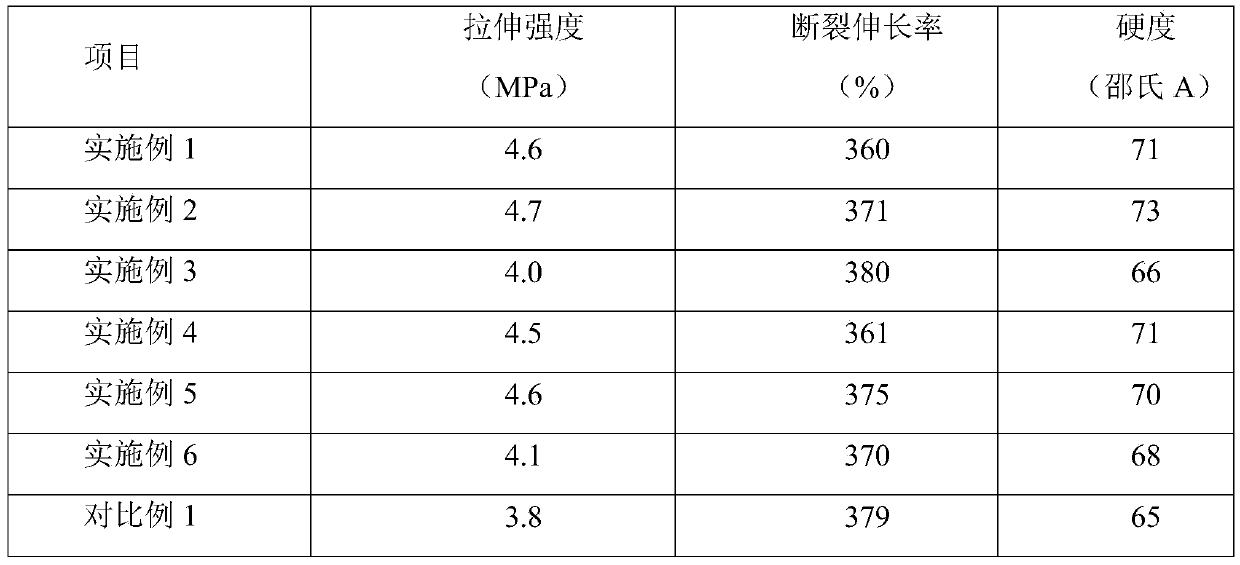

Method used

Image

Examples

Embodiment 1

[0025] Add 228g of bisphenol A and 9g of solid potassium hydroxide catalyst into a 5L stainless steel reactor, replace with nitrogen, and measure the oxygen content in the reactor to be less than 80ppm. The temperature of the reaction kettle was raised to 105° C., and dehydration under reduced pressure was carried out by nitrogen bubbling. Keep the temperature in the kettle at 110±2°C and the pressure at 0.2±0.2MPa, continuously add 2273g of propylene oxide, and then react under internal pressure for 30 minutes to remove unreacted propylene oxide. Then slowly add 499g of ethylene oxide, carry out end-capping polymerization at 130°C, react under internal pressure for 30 minutes, cool down and discharge the material to obtain the crude polyether polyol of the present invention that has the effect of improving the hardness and strength of the shoe sole. things. Subsequently, the above-mentioned polyether polyol crude polymer is subjected to neutralization, adsorption, crystalliz...

Embodiment 2

[0027] Add 250g of bisphenol S and 9g of solid potassium hydroxide catalyst into a 5L stainless steel reactor, replace with nitrogen, and measure the oxygen content in the reactor to be less than 80ppm. The temperature of the reaction kettle was raised to 105° C., and dehydration under reduced pressure was carried out by nitrogen bubbling. Keep the temperature in the kettle at 82±2°C and the pressure at 0.2±0.2MPa, continuously add 2255g of propylene oxide, and carry out internal pressure reaction to remove unreacted propylene oxide. Then add 495g of ethylene oxide, carry out end-blocking polymerization at 130° C., and carry out internal pressure reaction to obtain the crude polymer of the polyether polyol described in the present invention, which has the function of improving the hardness and strength of shoe soles. Subsequently, the above-mentioned polyether polyol crude polymer is subjected to neutralization, adsorption, crystallization, filtration and refining treatment, a...

Embodiment 3

[0029] Add 106g of hydroquinone and 9g of solid potassium hydroxide catalyst in a 5L stainless steel reactor, replace with nitrogen, and measure the oxygen content in the reactor to be lower than 80ppm. The temperature of the reaction kettle was raised to 105° C., and dehydration under reduced pressure was carried out by nitrogen bubbling. Keep the temperature in the kettle at 138±2°C and the pressure at 0.2±0.2MPa, continuously add 2373g of propylene oxide, and carry out internal pressure reaction to remove unreacted propylene oxide. Then add 521g of ethylene oxide, carry out end-blocking polymerization at 130° C., and carry out internal pressure reaction to obtain the crude polymer of the polyether polyol described in the present invention which has the effect of improving the hardness and strength of shoe soles. Subsequently, the above-mentioned polyether polyol crude polymer is subjected to neutralization, adsorption, crystallization, filtration and refining treatment, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com