High-stain-resistance waterborne top coating, preparation method thereof, application of the top coating, and woodware

A water-based topcoat and stain-resistant technology, applied in the field of coatings, can solve the problems that restrict the application of water-based wood paint, affect the appearance of the paint film, and the surface is easy to be polluted, so as to achieve the goal of not affecting the surface smoothness, good stain resistance, and preparation The method is simple and feasible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

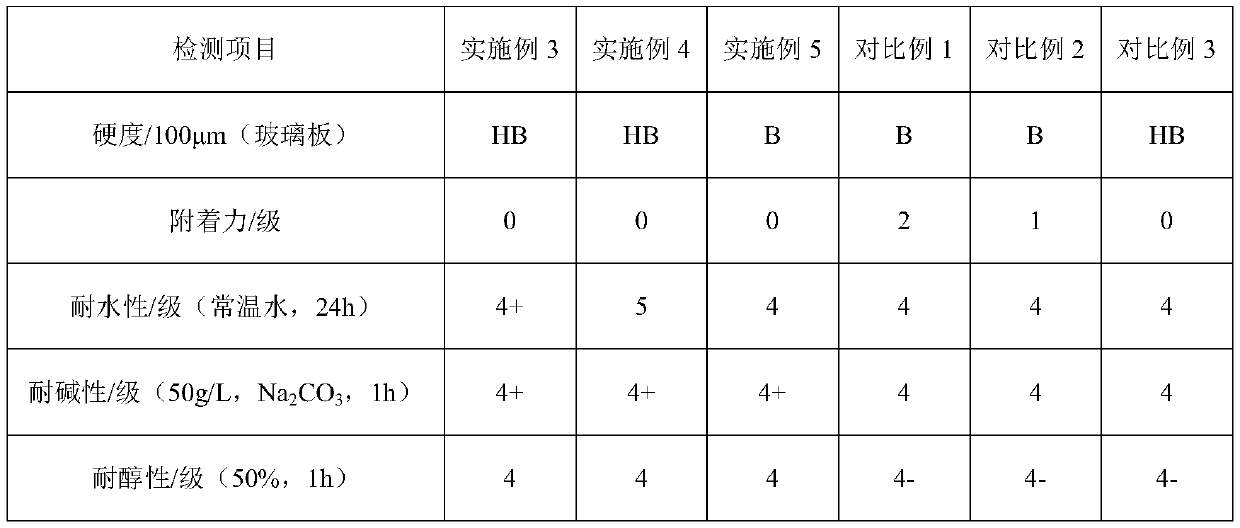

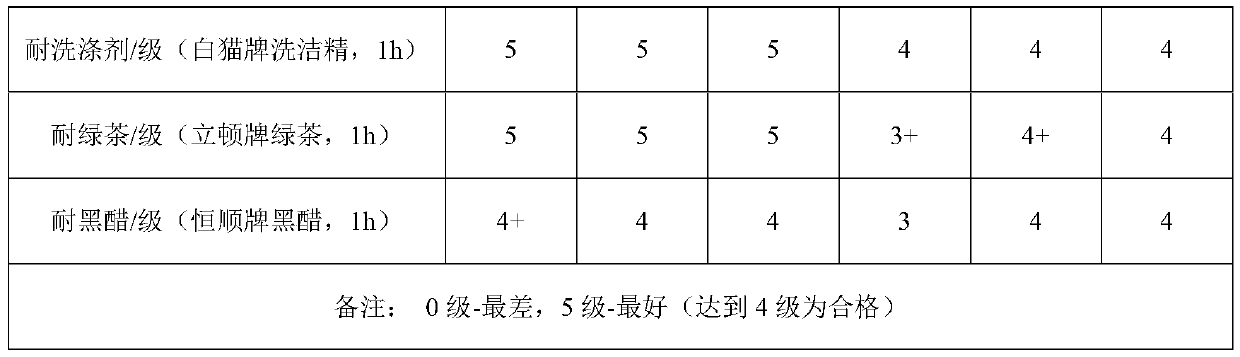

Examples

Embodiment 1

[0036] This embodiment provides a kind of highly stain-resistant water-based finish paint, and the preparation method of this water-based finish paint may further comprise the steps:

[0037] (1) Weigh 100g of water, 30g of dispersant, 2-6g of defoamer, 900g of titanium dioxide, 1g of water-based rheology additive, and 1g of pH regulator, and set aside. Among them, the dispersant is a copolymer solution containing a pigment affinity group, and the commercially available BYK-2081 can be selected; the defoamer is a silicone defoamer, and the commercially available BYK-024 can be specifically selected; Titanium dioxide is a general-purpose rutile titanium dioxide prepared by the chlorination method. Specifically, the commercially available DuPont R-706 can be selected; the water-based rheological additive is a polyether polyurethane associative rheological additive with 25% active ingredients, and the specific optional rheological additive is The commercially available Hemings Rh...

Embodiment 2

[0044] This embodiment provides a kind of highly stain-resistant water-based finish paint, and the preparation method of this water-based finish paint may further comprise the steps:

[0045] (1) Weigh 300g of water, 70g of dispersant, 6g of defoamer, 600g of titanium dioxide, 5g of water-based rheology additive, and 5g of pH regulator, and set aside. Among them, the dispersant is commercially available BYK BYK-2081; the defoamer is an organosilicon defoamer, specifically commercially available BYK BYK-024; titanium dioxide is a general-purpose rutile titanium dioxide prepared by the chlorination method. Specifically, commercially available DuPont R-706 can be selected; the water-based rheological additive is a polyether polyurethane associative rheological additive with 25% active parts, and commercially available Hemings Rheolate 299 can be specifically selected; the pH regulator contains 5 % water content of 2-amino-2-methyl-1-propanol, specifically commercially available A...

Embodiment 3

[0052] This embodiment provides a kind of highly stain-resistant water-based finish paint, and the preparation method of this water-based finish paint may further comprise the steps:

[0053] (1) Weigh 250g of water, 40g of dispersant, 5g of defoamer, 700g of titanium dioxide, 3g of water-based rheology additive, and 2g of pH regulator, and set aside. Among them, the dispersant is commercially available BYK BYK-2081; the defoamer is an organosilicon defoamer, specifically commercially available BYK BYK-024; titanium dioxide is a general-purpose rutile titanium dioxide prepared by the chlorination method. Specifically, commercially available DuPont R-706 can be selected; the water-based rheological additive is a polyether polyurethane associative rheological additive with 25% active parts, and commercially available Hemings Rheolate 299 can be specifically selected; the pH regulator contains 5 % water content of 2-amino-2-methyl-1-propanol, specifically commercially available A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com