Lithium ion battery electrolyte considering high-temperature and low-temperature properties

A lithium-ion battery, low-temperature performance technology, applied in secondary batteries, secondary battery repair/maintenance, circuits, etc., can solve the problems of low ion and electronic conductivity, accelerated electrolyte decomposition, and poor battery cycle performance. Achieve the effects of good film-forming performance, good charge-discharge performance, and good low-temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A method for preparing a lithium-ion battery with both high-temperature and low-temperature performance, comprising the following steps:

[0021] Step 1: In a glove box filled with argon, ethylene carbonate, propylene carbonate, ethyl methyl carbonate, and ethyl acetate are mixed in a volume ratio of = 1:2:3:2 to prepare a mixed solvent;

[0022] Step 2: Lithium tetrafluoroborate (LiBF4), bisoxalate lithium borate (LiBOB) and bis(fluoromalonate) lithium borate (LiBFMB) lithium salt with a mass ratio of 4:2:1 are dissolved in the In the mixed solvent, add additives fluoroethylene carbonate and ethylene sulfate, wherein the mass ratio of fluoroethylene carbonate and ethylene sulfate in the additive is 1:1, and prepare an electrolyte solution, wherein the content of non-aqueous organic solvent is 80% %, the content of lithium salt is 15%, and the content of additives is 5%. Seal the prepared electrolyte and store it for 24 hours to obtain a lithium-ion battery electrolyte ...

Embodiment 2-6

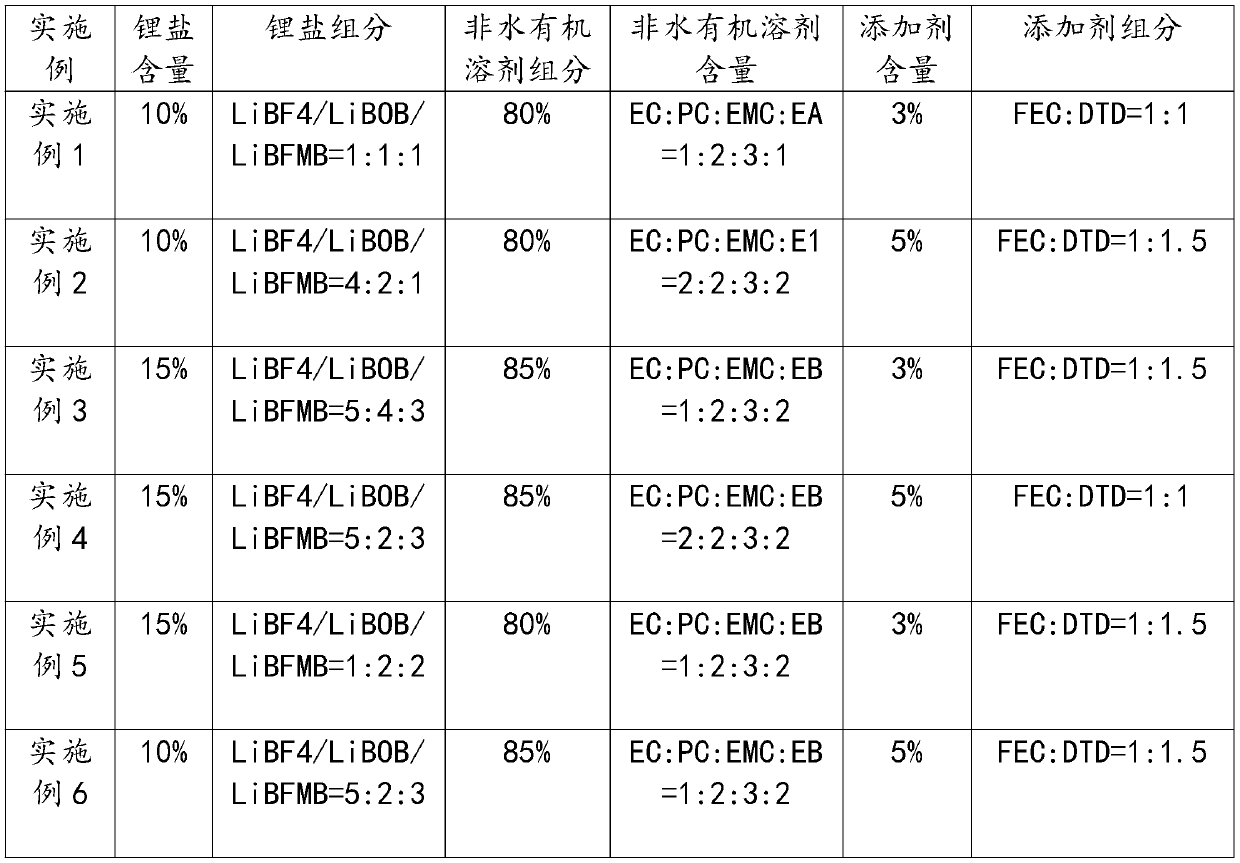

[0027] Except that the electrolyte preparation process and the lithium ion battery preparation process are the same, the lithium salt ratio, the non-aqueous organic solvent ratio, and the additive ratio are all different from those in Example 1, as shown in Table 1:

[0028] Table 1 is the content table of each component of the electrolyte of embodiment 1-6

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com