A kind of flux for submerged arc welding that can reduce the hydrogen diffusion of weld metal and its preparation method

A technology of weld metal and submerged arc welding, which is applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve the problems of inapplicable production development, ineffective removal of diffusible hydrogen, etc., and achieve good weld metal deposition. , good mechanical properties, strong slag-making ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

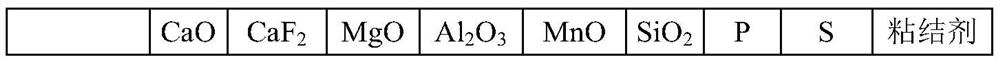

[0029] The details of the preparation method of the flux are as follows:

[0030] 1) Ingredients:

[0031] According to the mass percentage of the main components of the flux, the ratio of various raw materials is carried out, and the raw materials are ground, and the particle size is required to be 240-280 mesh;

[0032] 2) Dry mix:

[0033] After the raw material ratio is good, stir and mix well, and the time is controlled at more than 30 minutes, so that it can be fully stirred;

[0034] 3) wet mixing:

[0035] In the wet mixing, the traditional sodium potassium water glass binder is replaced by adding fine powdered polyvinyl alcohol (PVA) binder, and its weight is controlled at 15% of the total weight of the flux raw material, and it is added slowly and continuously stirred. It is fully stirred and mixed;

[0036] 4) Granulation:

[0037] Mix the wet-mixed raw materials into granules with a vibrating container, and screen them with an 80-mesh sieve;

[0038] 5) Dryin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com