Preparation method for boron-doped diamond film

A boron-doped diamond and thin film preparation technology, which is applied in the field of BDD thin film preparation, can solve problems such as hot wire oxidation and broken wires, affect product quality, and uneven boron content, and achieve simple control, good deposition and doping effects, and safe operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

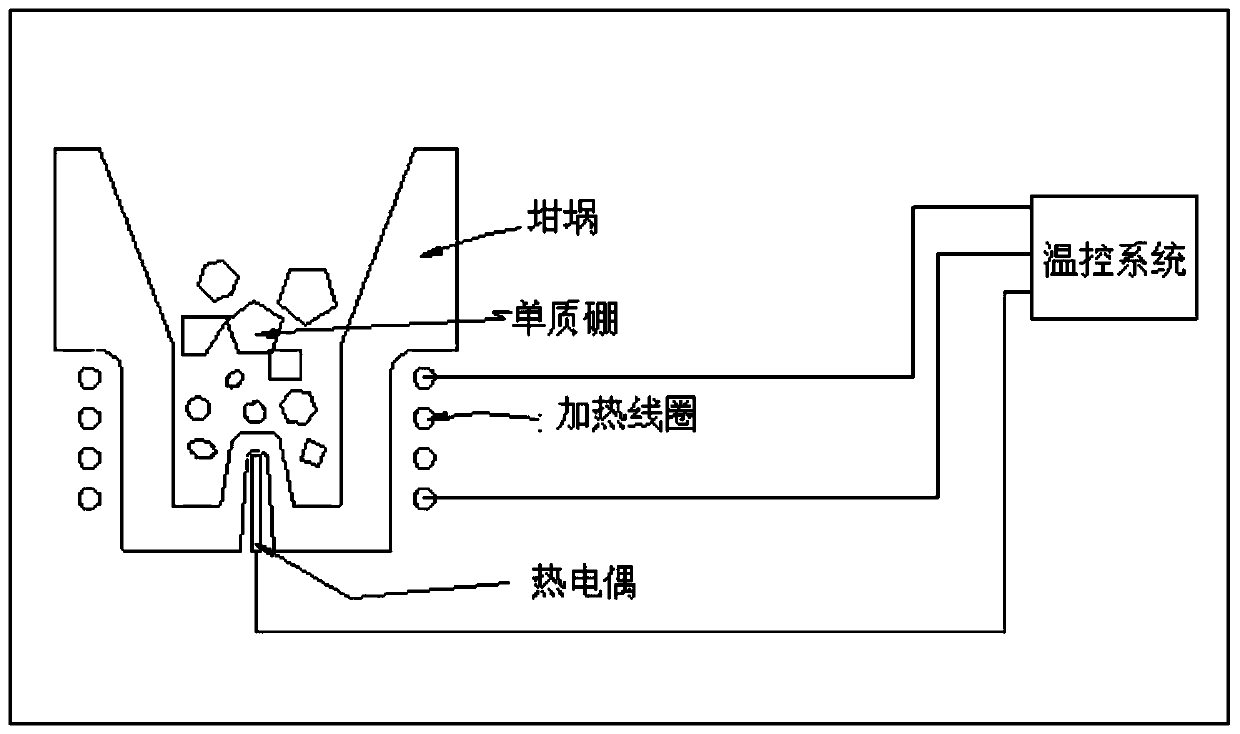

[0031] This embodiment provides a method for preparing a boron-doped diamond film, using a filament pyrolytic CVD method, using hydrogen and methane as raw material gases, and using simple boron as a doping source to synthesize and dope a boron-doped diamond film.

[0032] First turn on the power, preheat the crucible to the preset low temperature, the preset low temperature can be 300-400°C, when the CVD diamond deposition conditions in the deposition chamber meet the deposition requirements, a or a plurality of crucibles are heated to the sublimation control temperature for sublimation of elemental boron, wherein the heating temperature of the crucible is measured by a thermocouple and transmitted to a temperature control system, and the temperature for heating the crucible is controlled by the temperature control system The power of the heating coil is kept consistent with the set temperature. The temperature of the crucible can be controlled by a program and set in conjunct...

Embodiment 2

[0048] The features of this embodiment that are the same as those of Embodiment 1 will not be described in detail. The features of this embodiment that are different from Embodiment 1 are:

[0049] The preset low temperature may be 300°C.

[0050] The CVD diamond deposition conditions in the deposition chamber meet the deposition requirements, including deposition chamber pressure of 5-6 torr, methane concentration (flow rate) of 2%, substrate temperature of 700°C, and hot wire temperature of 1800-2000°C.

Embodiment 3

[0052] The features of this embodiment that are the same as those of Embodiment 1 will not be described in detail. The features of this embodiment that are different from Embodiment 1 are:

[0053] The preset low temperature may be 350°C.

[0054] The CVD diamond deposition conditions in the deposition chamber meet the deposition requirements, including a deposition chamber pressure of 80 torr, a methane concentration (flow rate) of 8%, a substrate temperature of 900°C, and a filament temperature of 2200-2500°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com