A kind of low hygroscopicity smaw electrode

A low hygroscopicity, welding rod technology, applied in the direction of welding equipment, welding medium, welding/cutting medium/material, etc., can solve the problems of high water content, easy moisture absorption, etc., achieve stable composition, strong slagging ability, and weld seam Good effect of metal deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

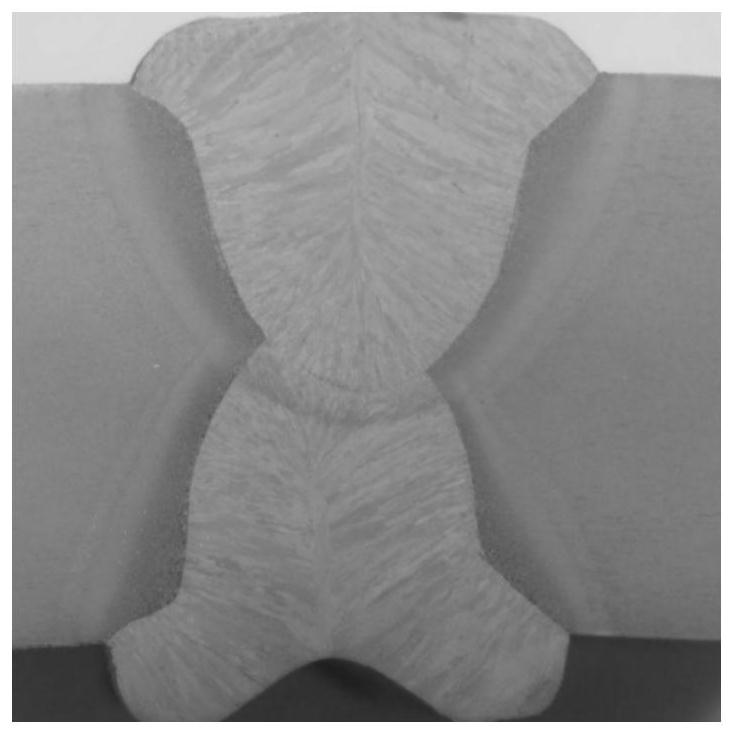

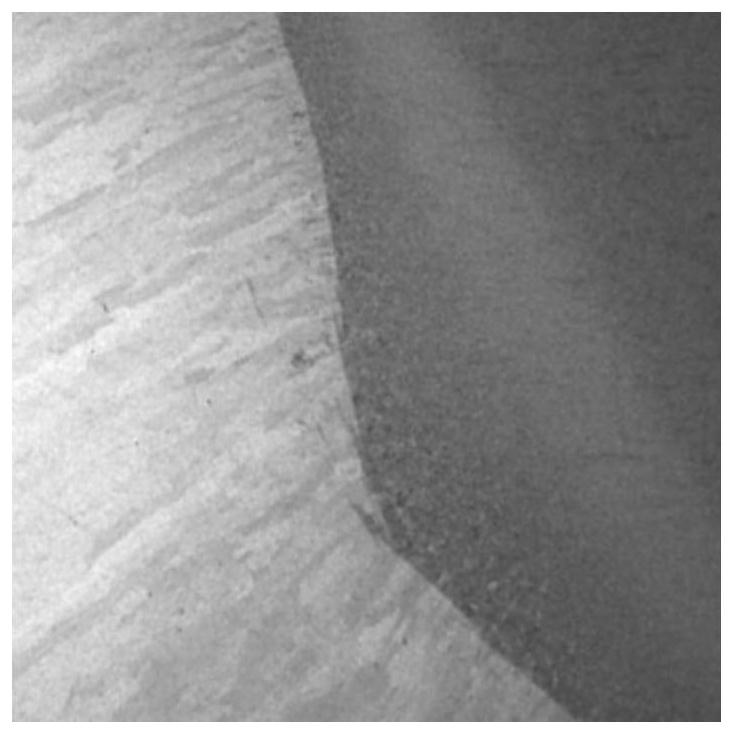

Image

Examples

Embodiment 1

[0029] A low hygroscopicity SMAW electrode includes two parts: a welding core and a coating.

[0030] The drug skin includes the following raw materials in parts by mass: see Table 1 below.

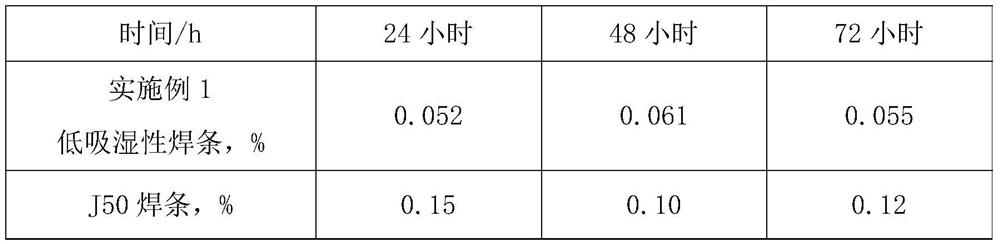

[0031] Table 1 Composition of drug skin (parts by weight)

[0032] marble Silicate High carbon ferrochromium Titanium dioxide Mixed rare earth binder 35 15 15 8 8 15

[0033] The mixed rare earth ratio (by mass fraction):

[0034] Adopt the composition ratio of yttrium oxide 25%, cerium oxide 45%, lanthanum oxide 30%;

[0035] The binder ratio (by mass fraction):

[0036] 25 parts of hydroxypropyl methylcellulose ether, 55 parts of polyvinyl alcohol (PVA), 4.5 parts of sodium silicate aqueous solution (the mass ratio of sodium silicate and water is controlled at 1:1.5), 15 parts of latex powder, 0.5 parts of hydrochloric acid ;

[0037] The preparation method of the binder:

[0038] Mix 25 parts of hydroxypropyl methylcellulose ether, 55 parts of pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com