Ion repair liquid preparation method

A technology of repairing liquid and ions, which is applied in the field of agriculture, can solve the problems of low preparation efficiency, incomplete nutrition of products, cumbersome preparation methods, etc., and achieve the effects of high preparation efficiency, improvement of osmotic adjustment substances, and promotion of plant rooting and survival

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

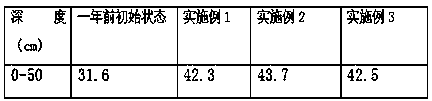

Examples

Embodiment 1

[0033] The preparation method of embodiment 1 ion restoration liquid

[0034] (1) Preparation of chicken bone pulp

[0035] The preparation method of the chicken bone pulp of the present invention is as follows: rinse the debroiled chicken bones, use Bacillus subtilis (preservation number BNCC340673) neutral protease and type 54 acid protease, mix according to the weight ratio of 7:11, and then add 0.5% vitamin E. After stirring evenly, extract in water at 82°C for 3.6 hours, separate the chicken bone oil and take the remaining residue, then adjust the pH value to 3.5 with citric acid to obtain chicken bone pulp.

[0036] (2) Weighing of raw materials

[0037] According to the formula, weigh each raw material.

[0038] The formula includes the following raw materials in parts by weight: chicken bone pulp, raw egg yolk powder, green hawthorn powder, Tenebrio molitor powder, zinc sulfate heptahydrate, ammonium tetramolybdate, catalase CAT, beneficial microbial agent, selenium ...

Embodiment 2

[0067] The preparation method of embodiment 2 ion restoration liquid

[0068] Basically the same as Example 1, the difference is only in parts by weight: specifically, in this Example 2, the following raw materials are included in parts by weight: 200 parts of chicken bone pulp, 55 parts of raw egg yolk powder, 14 parts of green hawthorn powder, Tenebrio molitor 6 parts of powder, 0.8 parts of zinc sulfate heptahydrate, 1 part of ammonium tetramolybdate, 4 parts of catalase CAT, 10 parts of beneficial microbial agent, 1.8 parts of selenated polysaccharide, 1 part of Lactobacillus brown ring, 0.7 parts of licorice extract 3 parts of maitake polysaccharide, 10 parts of dodder powder, 22 parts of sodium humate, 0.11 parts of sage extract, 0.11 part of silkworm chrysalis extract, 6 parts of grape skin extract, 9 parts of monocalcium phosphate, β-fold barrel 7 parts of phytase, 0.25 parts of agricultural rare earth nitrate.

Embodiment 3

[0069] The preparation method of embodiment 3 ion restoration liquid

[0070] Basically the same as Example 1, the difference is only in parts by weight: specifically, in this Example 3, the following raw materials are included in parts by weight: 150 parts of chicken bone pulp, 60 parts of raw egg yolk powder, 12 parts of green hawthorn powder, Tenebrio molitor 7 parts of powder, 0.6 parts of zinc sulfate heptahydrate, 1.3 parts of ammonium tetramolybdate, 3 parts of catalase CAT, 14 parts of beneficial microbial agent, 1.5 parts of selenated polysaccharide, 1.3 parts of milk boletus brown ring, 0.6 parts of licorice extract 6 parts of maitake polysaccharide, 7 parts of dodder powder, 27 parts of sodium humate, 0.09 parts of sage extract, 0.35 parts of silkworm chrysalis extract, 4 parts of grape skin extract, 9 parts of monocalcium phosphate, β-fold barrel 5 parts of phytase, 0.5 part of agricultural rare earth nitrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com