Treatment method of high-salt and high-chroma wastewater

A treatment method and technology for wastewater, applied in the field of water treatment, can solve the problems of difficulty in reducing the chromaticity of wastewater, difficulty in treating wastewater with high salt and high chroma, and achieve the effect of normal resin adsorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

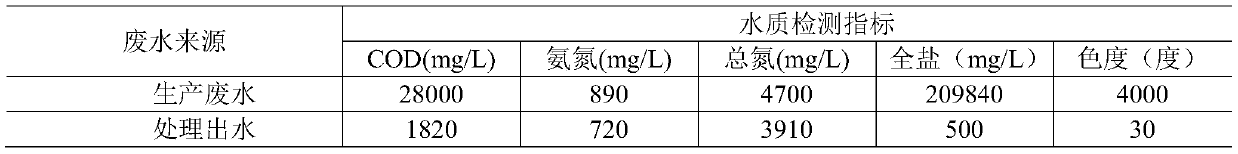

Examples

Embodiment 1

[0039] This embodiment provides a treatment method for high-salt, high-chroma wastewater, the specific steps are as follows:

[0040] (1) Send the collected waste water into the adjustment tank, adjust the pH to be acidic, centrifuge, and send the effluent to the primary resin adsorption tower for a resin adsorption. The resin is an aminated ultra-high cross-linked styrene resin, and the waste water The flow rate is controlled at 10-20BV, and the flow rate is controlled at 1.0-2.0BV / h;

[0041] (2) adjust the pH value of the effluent in (1) to 6;

[0042] (3) the effluent in (2) is passed into the ozone tower, and in the ozone tower, an alumina catalyst is added, taking the water inlet volume as a benchmark, the adding volume ratio of the catalyst is 20%, and the feed concentration of the ozone 5.0mg / min, oxidation treatment time is 30min;

[0043] (4) Regulate (3) middle effluent pH to be alkaline;

[0044](5) Send the effluent in (4) to the secondary resin adsorption towe...

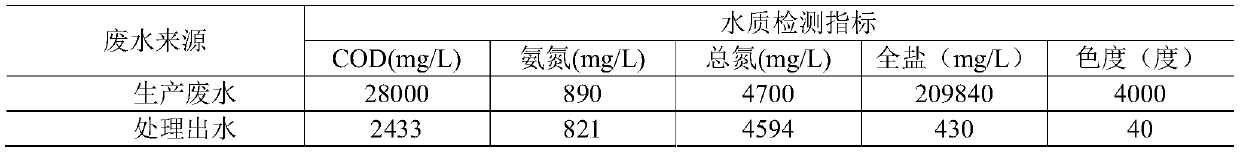

Embodiment 2

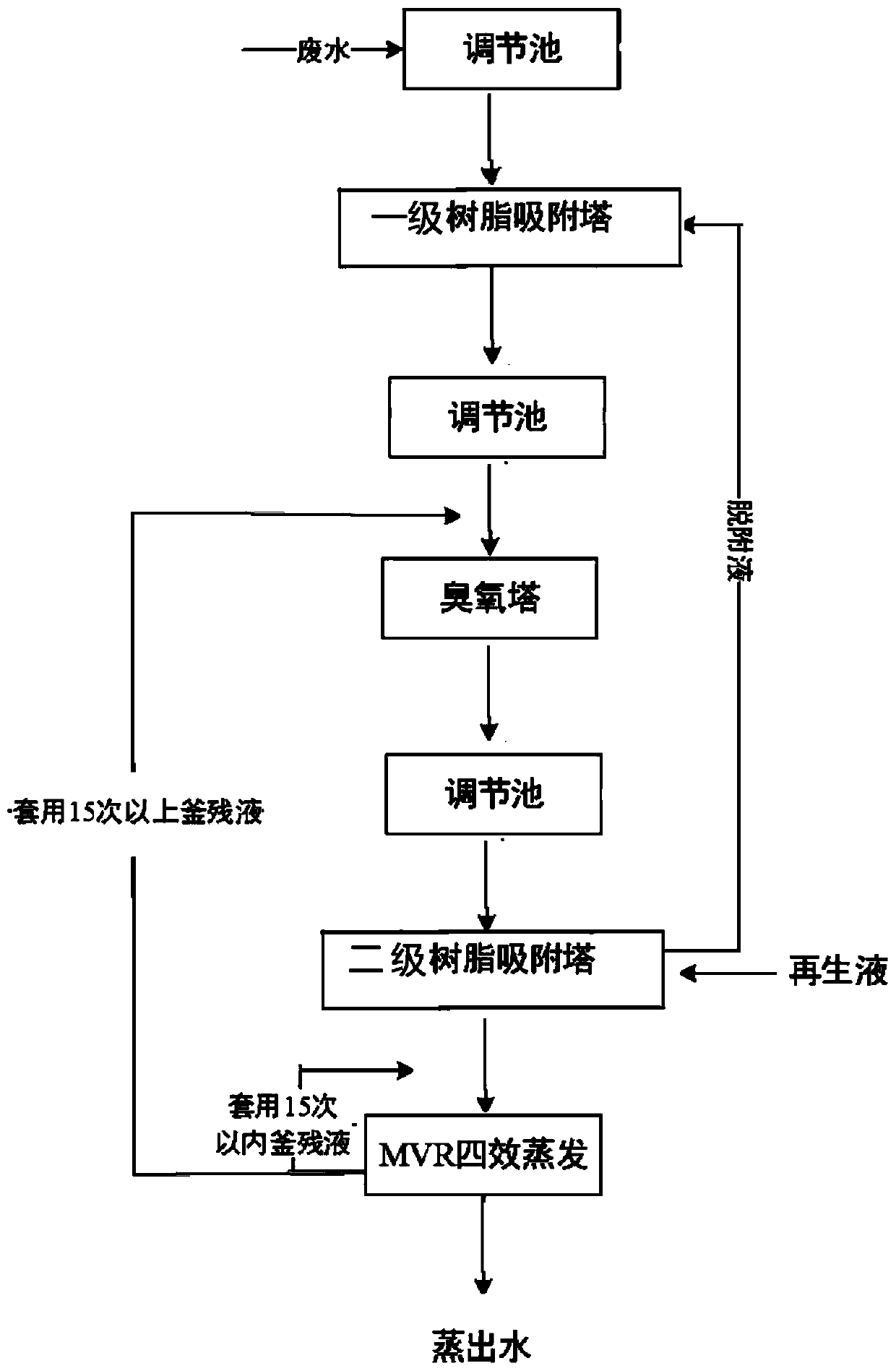

[0050] Such as figure 1 As shown, the present embodiment provides a treatment method for high-salt, high-chroma wastewater, and the specific steps are as follows:

[0051] (1) Send the collected waste water into the adjustment pool, adjust the pH value to 2, and carry out centrifugation. The effluent is sent to the primary resin adsorption tower for primary resin adsorption. The resin is an aminated ultra-high cross-linked styrene resin, The waste water flow rate is controlled at 10-20BV, and the flow rate is controlled at 1.0-2.0BV / h;

[0052] (2) adjust the pH value of the effluent in (1) to 5;

[0053] (3) the effluent in (2) is passed into the ozone tower, and in the ozone tower, add titanium dioxide catalyst, take the water inflow volume as a benchmark, the adding volume ratio of the catalyzer is 20%, and the feeding concentration of the ozone is 4.0mg / min, oxidation treatment time is 10min;

[0054] (4) adjust the pH value of the effluent in (3) to 11;

[0055] (5) S...

Embodiment 3

[0063] (1) Send the collected waste water into the adjustment tank, adjust the pH value to 5, and carry out centrifugation. The effluent is sent to the primary resin adsorption tower for resin adsorption. The flow rate is 10-20BV, and the flow rate is 1.0-2.0BV / h;

[0064] (2) adjust the pH value of the effluent in (1) to 8;

[0065] (3) the effluent in (2) is passed into the ozone tower, and in the ozone tower, a manganese dioxide catalyst is added, taking the water inflow volume as a benchmark, the adding volume ratio of the catalyst is 20%, the feeding of the ozone The concentration is 6.0mg / min, and the oxidation treatment time is 30min;

[0066] (4) adjust the pH value of the effluent in (3) to 11;

[0067] (5) Send the effluent in (4) to the secondary resin adsorption tower, and use ultra-high cross-linked styrene resin for secondary resin adsorption treatment. The waste water flow rate is controlled at 40-100BV, and the flow rate is controlled at 2.0-4.0BV / h;

[0068...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com