Sewage treatment process and device capable of achieving surface IV-class water discharge

A sewage treatment device and sewage treatment technology, applied in water/sewage treatment, oxidized water/sewage treatment, water/sewage multi-stage treatment, etc., to achieve the effect of reducing pollution, reducing cleaning cycle, and maintaining adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

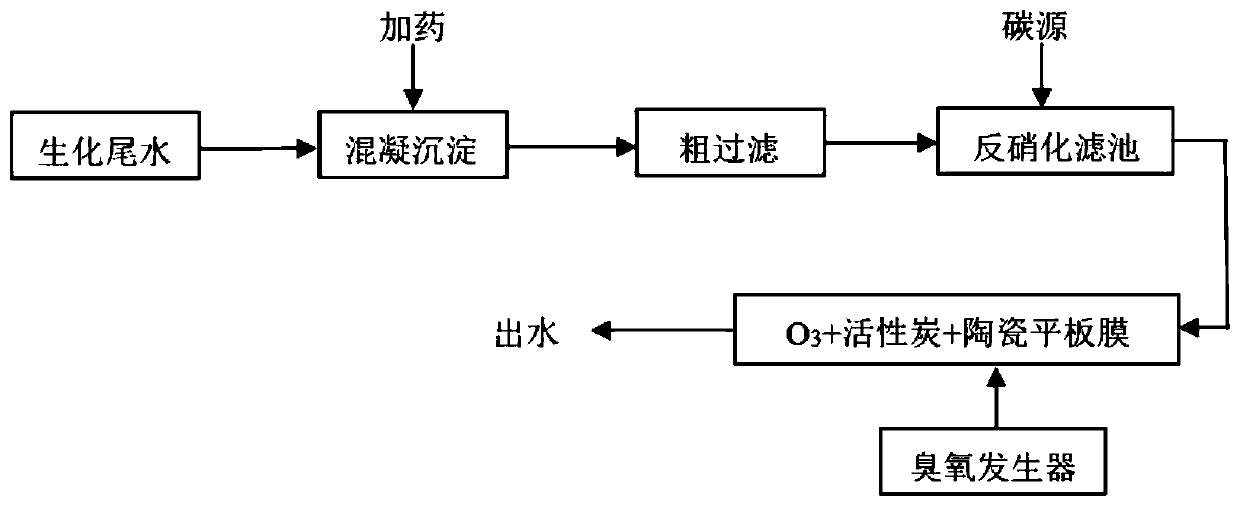

[0078] The waste water to be treated in the present invention mainly comes from the secondary biochemical effluent of the paper mill, and its indicators are generally COD120mg / L, pH about 7.8, total phosphorus (TP) about 12mg / L, and total nitrogen about 15mg / L.

[0079] The steps taken include:

[0080] Step 1: Add a flocculant mixed with polyaluminum chloride and polyaluminum ferric chloride in a weight ratio of 2:1 to the effluent from the secondary biochemical treatment. The amount of flocculant added is 75ppm; at the same time, 15ppm of coagulant cations are added Non-toxic polyacrylamide is used for flocculation treatment, and the water produced by flocculation is successively settled by inclined plate and coarsely filtered;

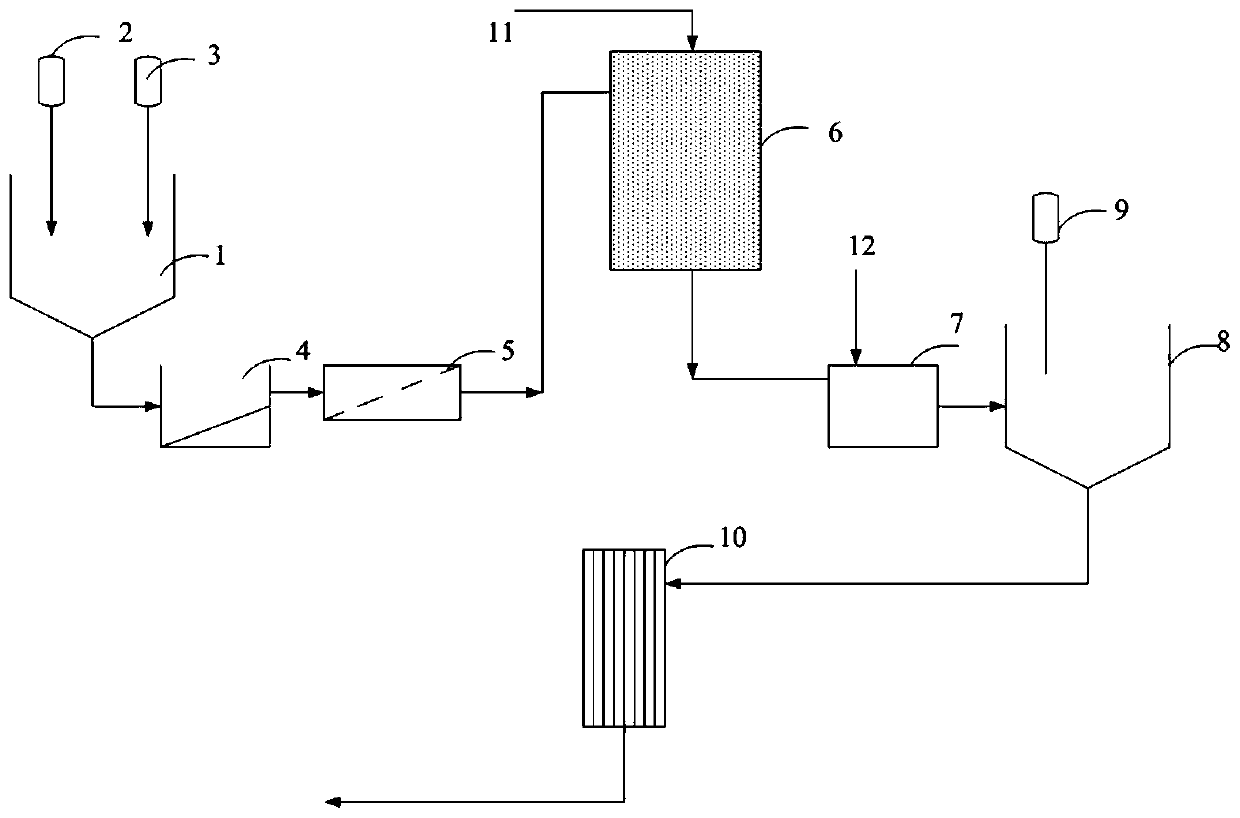

[0081] Step 2: The clear liquid obtained in step 1 enters the denitrification biofilter for denitrification treatment to remove nitrate nitrogen in the sewage; wherein, the average diameter of the filler used in the denitrification biofilter is 5~6m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com