Ytterbium-doped active optical fiber and preparation method thereof

A technology of optical fiber preform and optical fiber, which is applied in the field of ytterbium-doped active optical fiber and its preparation, can solve the problems that the concentration of ytterbium ions cannot be increased infinitely, and achieve the effects of reducing nonlinear effects, improving cladding absorption, and reducing the length of optical fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] The preparation method of above-mentioned ytterbium-doped active optical fiber, it comprises the steps:

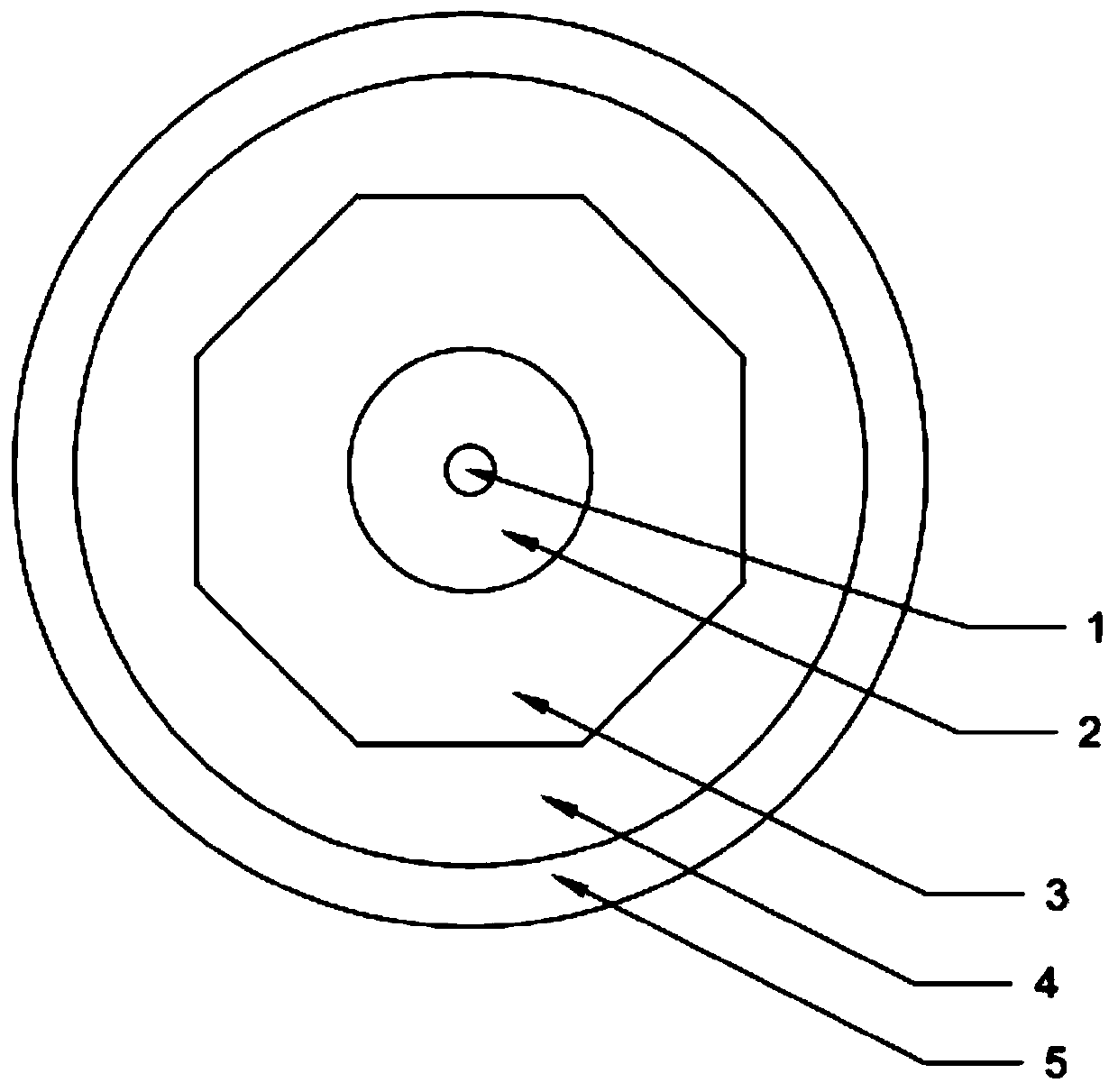

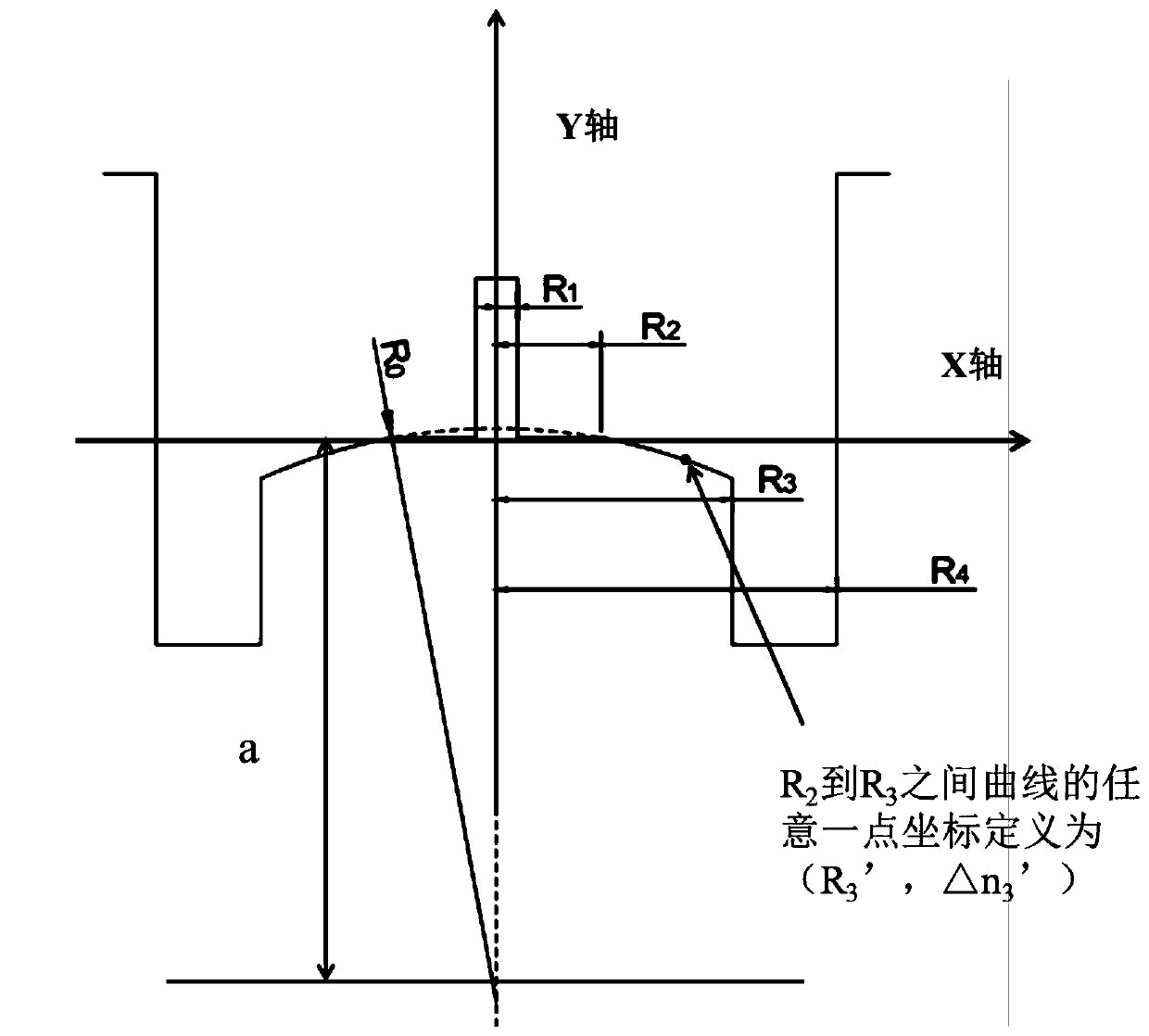

[0061] (1) Pretreatment of the substrate tube: Pickling of the substrate tube and preheating of the substrate tube effectively eliminate impurities and air bubbles on the inner wall of the substrate tube. The substrate tube is finally collapsed to form the first inner cladding 2 .

[0062] (2) Pass the base tube into SiCl at 1500-1650°C 4 Gas for soot body deposition of silica, SiCl 4 The volume flow rate of the feed is 100-300 sccm. After the deposition, the tail pipe of the base pipe is cut off, and then immersed in the aqueous solution 1 for 0.2-1 hour. After the immersion, N 2 Blow dry the moisture in the silicon dioxide loose body layer, soak in aqueous solution 1 containing AlCl 3 , YbCl 3 and H3PO 4 , AlCl 3 The molar concentration of YbCl is 0.01~3mol / L, YbCl 3 The molar concentration of H is 0.01~1mol / L, H 3 PO 4 The molar concentration is 0.01-2.5...

Embodiment 1

[0080] A highly absorbing ytterbium-doped active optical fiber and a preparation method thereof, comprising the steps of:

[0081] (1) Base tube pretreatment, pickling the base tube, preheating and effectively eliminating impurities and air bubbles on the inner wall of the base tube;

[0082] (2) Pass the substrate tube into SiCl at 1550°C 4 Gas for soot body deposition of silica, SiCl 4 The volume flow rate of feeding is 200sccm, cut off the tailpipe of the base pipe after the deposition is completed, and then soak in the soaking aqueous solution for 0.3 hours, and pass N into the base pipe after the immersion ends. 2 Blow dry the moisture in the silica loose body layer, and soak in the aqueous solution containing AlCl 3 , YbCl 3 and H 3 PO 4 , AlCl 3 The molar concentration is 0.25%, YbCl 3 The molar concentration is 0.05%, H 3 PO 4 The molar concentration is 0.2%;

[0083] (3) Reattach the tailpipe to the base pipe after drying in step (2), and first pass O at 860...

Embodiment 2

[0092] A highly absorbing ytterbium-doped active optical fiber and a preparation method thereof, comprising the steps of:

[0093] (1) Base tube pretreatment, preheating the base tube and effectively eliminating impurities and air bubbles on the inner wall of the base tube;

[0094] (2) Pass the substrate tube into SiCl at 1600°C 4 Gas for soot body deposition of silica, SiCl 4 The volume flow rate of feeding is 150 sccm, cut off the tail pipe of the substrate pipe after the deposition is completed, then immerse in the soaking aqueous solution for 0.5 hour, and feed N into the substrate pipe after the immersion ends. 2 Blow dry the moisture in the silica loose body layer, and soak in the aqueous solution containing AlCl 3 , YbCl 3 and H3PO 4 , AlCl 3 The molar concentration is 0.4%, YbCl 3 The molar concentration is 0.2%, H 3 PO 4 The molar concentration is 0.5%;

[0095] (3) Reattach the tailpipe to the base pipe after drying in step (2), and first pass O at 900°C. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com