Plasticizer-migration-resistant PVC and preparation method thereof

A technology resistant to plasticizers and lubricants, applied in the field of plasticizer-resistant PVC and its preparation, can solve the problems of high incidence of cancer, high carcinogenicity, etc., and achieve improved anti-ultraviolet effect and enhanced anti-oxidation ability, prolonging the effect of anti-oxidant aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

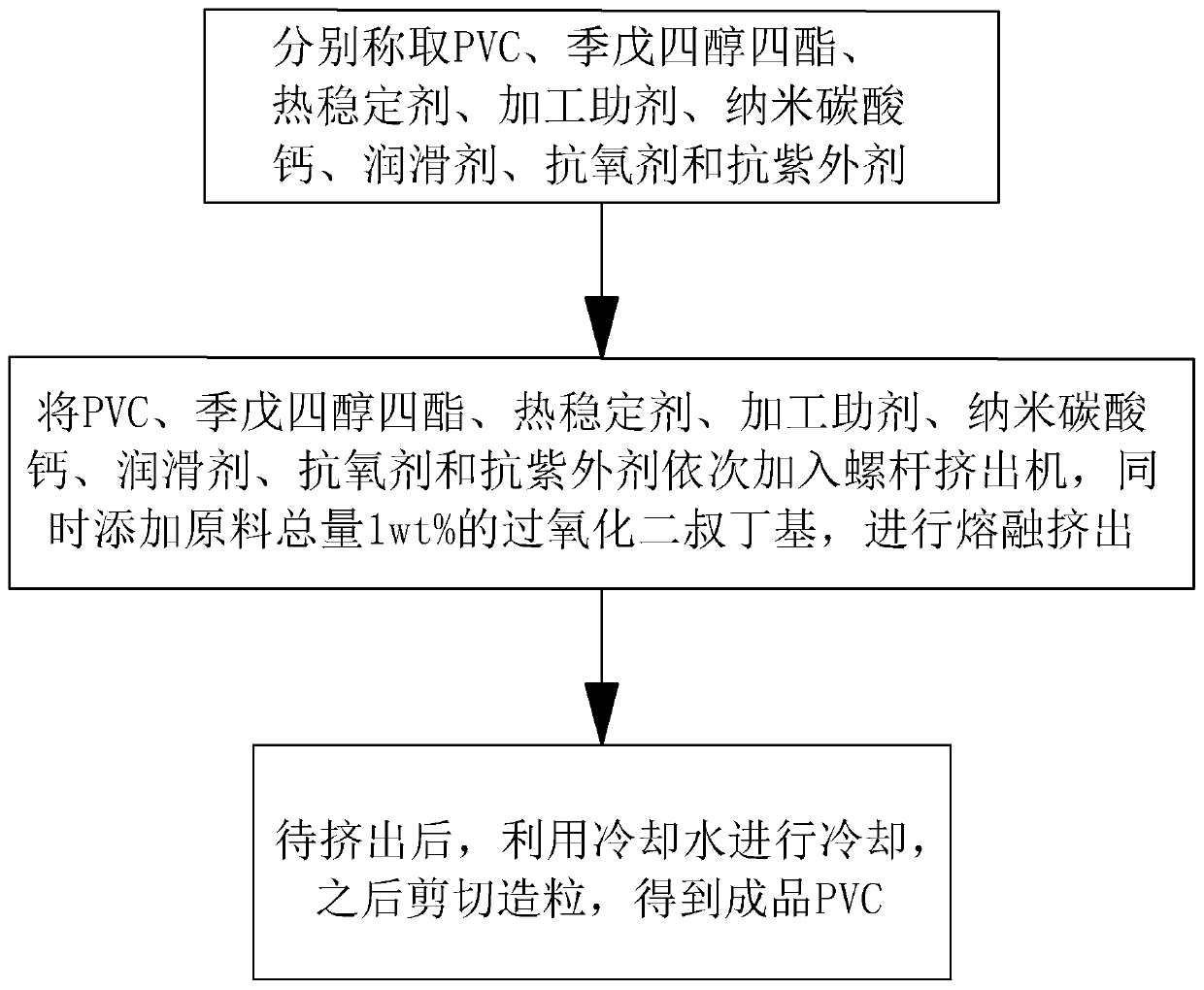

[0036] A preparation method for PVC resistant to plasticizer migration, mainly comprising the steps:

[0037] Step 1: Weigh 100Kg PVC, 30-80Kg pentaerythritol tetraester, 3-5Kg heat stabilizer, 1-2Kg processing aid, 1-50Kg nano calcium carbonate, 0.6-1.5Kg lubricant, 0.3-0.6Kg antioxidant And 0.2~0.5Kg anti-ultraviolet agent;

[0038] Step 2: Add the PVC, pentaerythritol tetraester, heat stabilizer, processing aid, nano-calcium carbonate, lubricant, antioxidant and anti-ultraviolet agent into the screw extruder in sequence, and add the raw material total Measure 1% di-tert-butyl peroxide for melt extrusion, the temperature of the screw extruder at the feeding place is controlled at 180-200°C, and the temperature of the extrusion head of the screw extruder is controlled at 150-160°C;

[0039] Step 3: after being extruded, cooling with cooling water, and then shearing and granulating to obtain finished PVC.

[0040] In this process, the screw extruder is in a vacuum state, and...

Embodiment 2

[0044] A preparation method for PVC resistant to plasticizer migration, mainly comprising the steps:

[0045] Step 1: Weigh 100Kg PVC, 30-80Kg pentaerythritol tetraester, 3-5Kg heat stabilizer, 1-2Kg processing aid, 1-50Kg nano calcium carbonate, 0.6-1.5Kg lubricant, 0.3-0.6Kg antioxidant And 0.2~0.5Kg anti-ultraviolet agent;

[0046]Step 2: Add the PVC, pentaerythritol tetraester, heat stabilizer, processing aid, nano-calcium carbonate, lubricant, antioxidant and anti-ultraviolet agent into the screw extruder in sequence, and add the raw material total Measure 1% diisopropyl peroxydicarbonate for melt extrusion, the temperature of the screw extruder at the feeding place is controlled at 180-200°C, and the temperature of the extrusion head of the screw extruder is controlled at 150-160°C ;

[0047] Step 3: after being extruded, cooling with cooling water, and then shearing and granulating to obtain finished PVC.

[0048] In this process, the screw extruder is in a vacuum st...

Embodiment 3

[0051] A preparation method for PVC resistant to plasticizer migration, mainly comprising the steps:

[0052] Step 1: Weigh 100Kg PVC, 30-80Kg pentaerythritol tetraester, 3-5Kg heat stabilizer, 1-2Kg processing aid, 1-50Kg nano calcium carbonate, 0.6-1.5Kg lubricant, 0.3-0.6Kg antioxidant And 0.2~0.5Kg anti-ultraviolet agent;

[0053] Step 2: Add the PVC, pentaerythritol tetraester, heat stabilizer, processing aid, nano-calcium carbonate, lubricant, antioxidant and anti-ultraviolet agent into the screw extruder in sequence, and add the raw material total Measure 1% benzoyl peroxide for melt extrusion, the temperature of the screw extruder at the feeding place is controlled at 180-200°C, and the temperature of the extrusion head of the screw extruder is controlled at 150-160°C;

[0054] Step 3: after being extruded, cooling with cooling water, and then shearing and granulating to obtain finished PVC.

[0055] In this process, the screw extruder is in a vacuum state, and the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com