MS sealant and preparation method thereof

A technology of silane-terminated polyether and polyether polyol, applied in the field of MS glue and its preparation, can solve the problems of harmfulness to human body and environment, many asphalt waterproof coatings, poor anti-aging performance, etc., and achieve excellent waterproof performance and anti-aging performance. Excellent, substrate adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

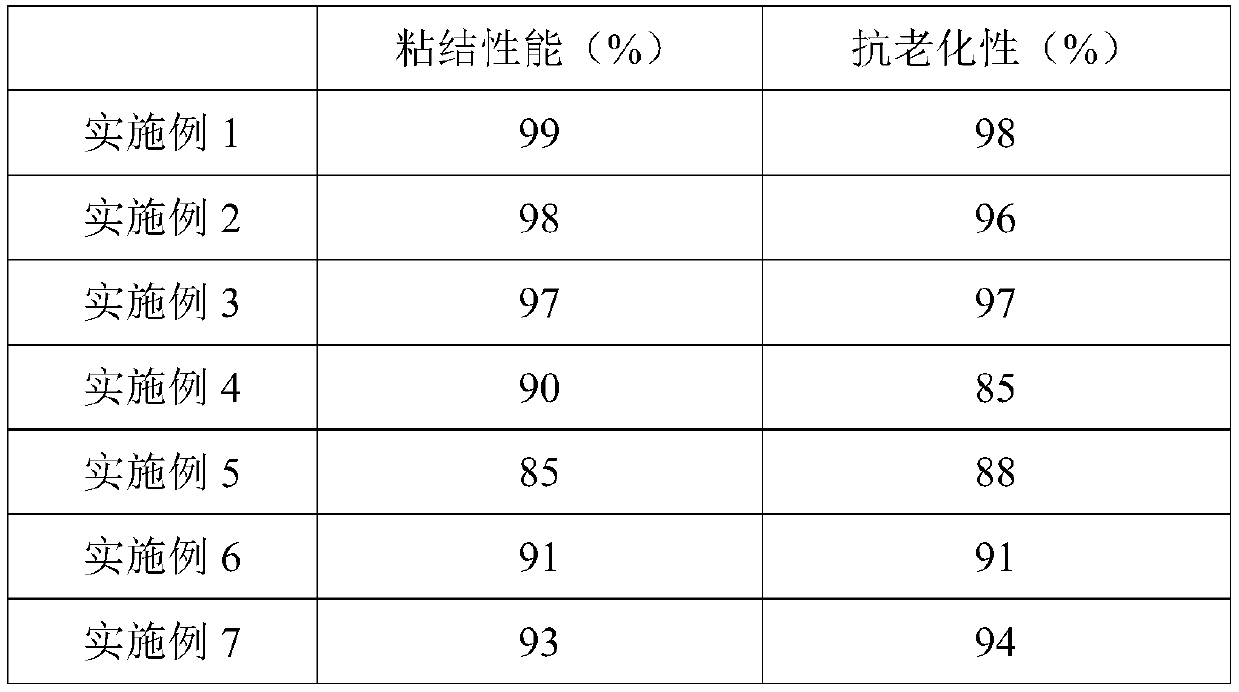

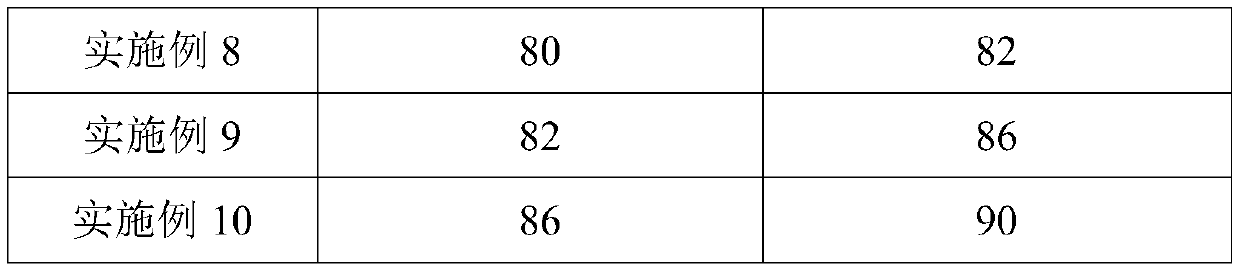

Examples

preparation example Construction

[0051] The second aspect of the present invention provides a method for preparing MS glue, which at least includes the following steps: mixing silane-terminated polyether, polyether polyol, and filler and stirring at 40-60°C for 1-3 hours to prepare MS glue.

[0052] In a preferred embodiment, the preparation method of the MS glue at least includes the following steps: mixing the silane-terminated polyether, the polyether polyol, and the filler, and then stirring at 50° C. for 2 hours to prepare the MS glue.

[0053] Hereinafter, the present invention is described in more detail through examples, but it should be understood that these examples are only illustrative and not restrictive. In addition, all raw materials are commercially available unless otherwise specified.

Embodiment 1

[0056] Embodiment 1 of the present invention provides an MS glue, which comprises the following components in parts by weight: 25 parts of silane-terminated polyether, 15 parts of polyether polyol, and 60 parts of filler.

[0057] The number average molecular weight of the silane-terminated polyether is 25,000.

[0058] The silane-terminated polyether is a silyl-terminated polyether, purchased from Jinjinle (Hunan) Chemical Co., Ltd.

[0059] The number average molecular weight of the polyether polyol is 3000.

[0060] The polyether polyols were purchased from Jinjinle (Hunan) Chemical Co., Ltd.

[0061] The filler is calcium carbonate, fumed white carbon black and titanium dioxide.

[0062] In parts by weight, there are 48 parts of calcium carbonate, 2 parts of fumed white carbon black, and 10 parts of titanium dioxide.

[0063] The calcium carbonate is pretreated calcium carbonate.

[0064] The pretreatment method of the calcium carbonate is: drying the calcium carbonate...

Embodiment 2

[0067] Example 2 of the present invention provides an MS glue, comprising the following components in parts by weight: 20 parts of silane-terminated polyether, 10 parts of polyether polyol, and 54.5 parts of filler.

[0068] The number average molecular weight of the silane-terminated polyether is 20,000.

[0069] The silane-terminated polyether is a silyl-terminated polyether, purchased from Jinjinle (Hunan) Chemical Co., Ltd.

[0070] The number average molecular weight of the polyether polyol is 1000.

[0071] The polyether polyols were purchased from Jinjinle (Hunan) Chemical Co., Ltd.

[0072] The filler is calcium carbonate, fumed white carbon black and titanium dioxide.

[0073] In parts by weight, there are 45 parts of calcium carbonate, 1.5 parts of fumed white carbon black, and 8 parts of titanium dioxide.

[0074] The calcium carbonate is pretreated calcium carbonate.

[0075] The pretreatment method of the calcium carbonate is: drying the calcium carbonate at 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com