Material pyrolysis gasification process, system and application

A technology of pyrolysis gasification and materials, which is applied in gasification process, granular/powdered fuel gasification, chemical industry, etc. It can solve the problems of high risk of secondary pollution, low calorific value of gas, etc., and achieve energy utilization efficiency High, high comprehensive calorific value, the effect of increased content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

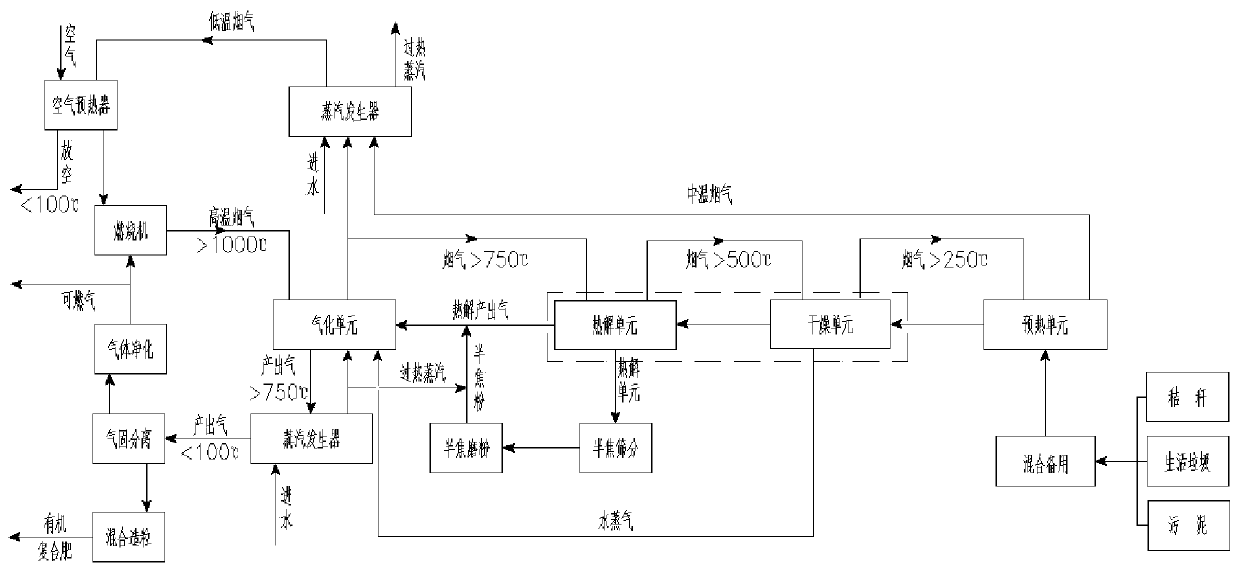

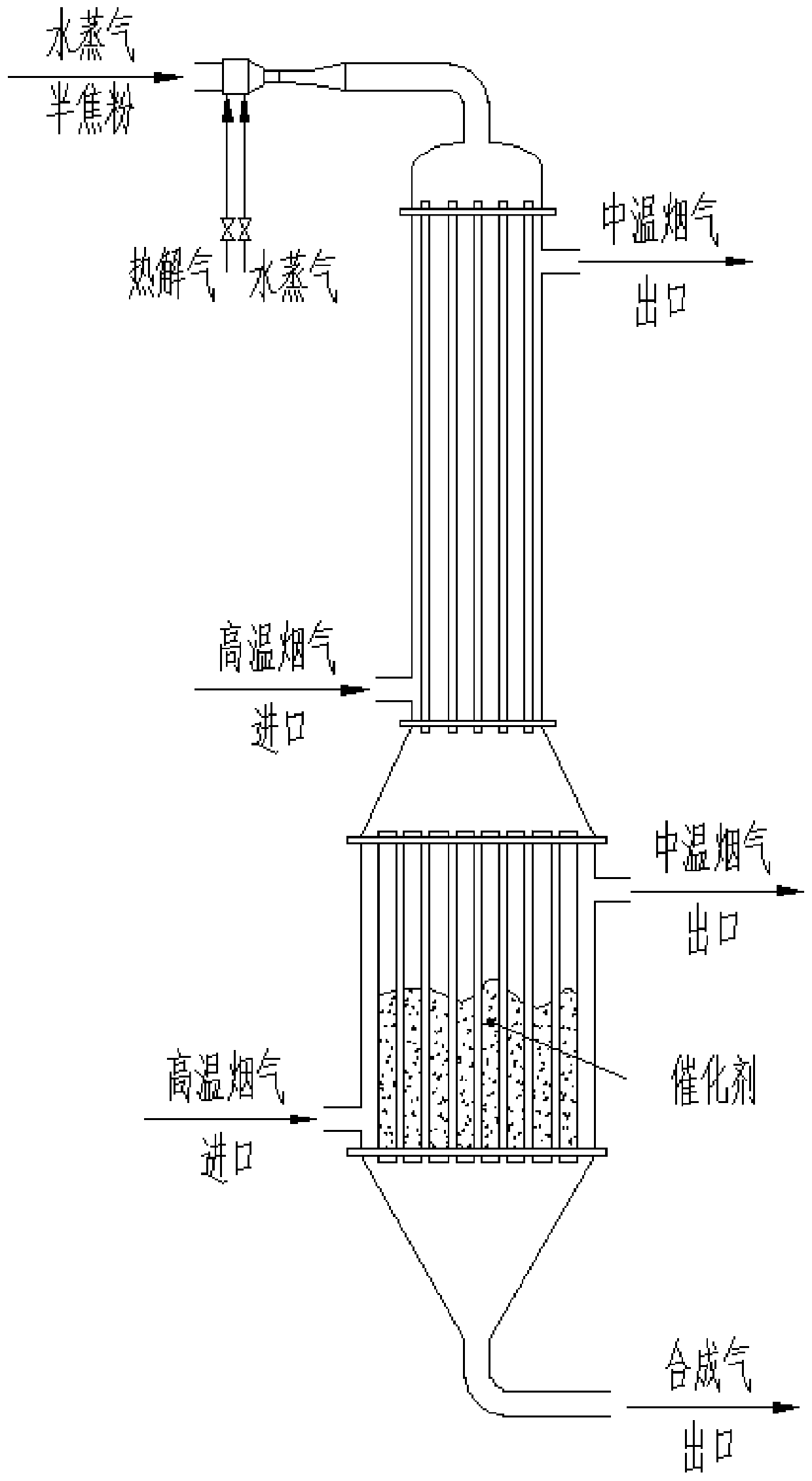

[0030] Follow the above technical solutions, such as Figure 1-3 As shown, this embodiment provides a pyrolysis and gasification system. Taking municipal solid waste as an example, the whole process mainly includes feeding, drying, pyrolysis, gasification, and energy recovery and reuse, and specifically includes the following steps:

[0031] First, the sludge, straw and domestic garbage are mixed and preheated after magnetic separation and other pretreatments. The preheated mixture is charged into the inner cylinder of the pyrolysis furnace; the inner cylinder filled with materials is placed in the pyrolysis furnace In the furnace roof, flue gas inlet and outlet pipes and pyrolysis gas outlet pipes are installed at the same time, and the flue gas inlet and outlet are equipped with switching valves to change the inlet heat source to meet the required heat for drying and pyrolysis respectively. The pyrolysis gas outlet is equipped with Gas flow meter and pressure regulating valve a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com