Composite cooling water disc and manufacturing method and application thereof

A cooling water, composite technology, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as the heat transfer coefficient of the device is not improved, copper cannot be exposed, copper ions leak, etc., to promote thermal isostatic Pressure welding effect, high industrial application value, effect of preventing copper leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

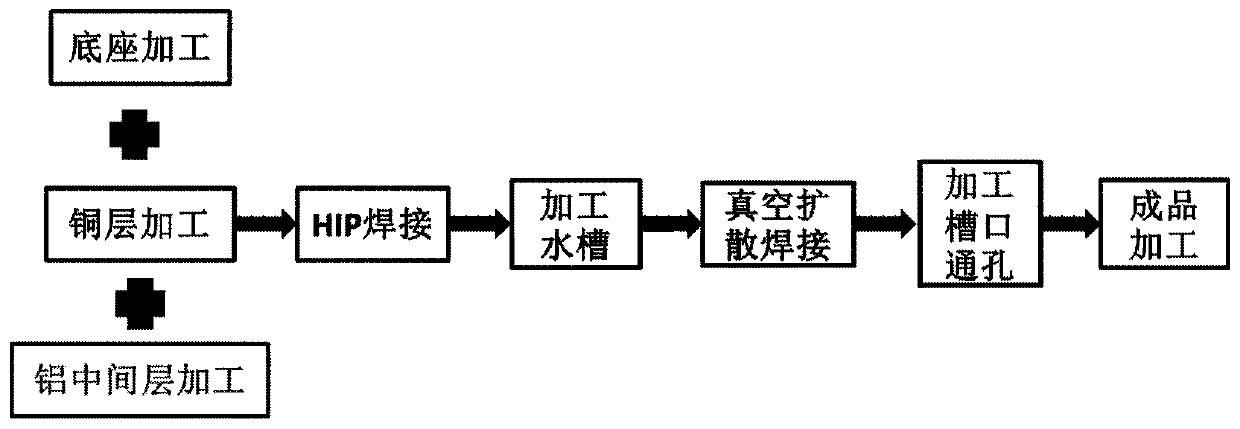

Method used

Image

Examples

Embodiment 1

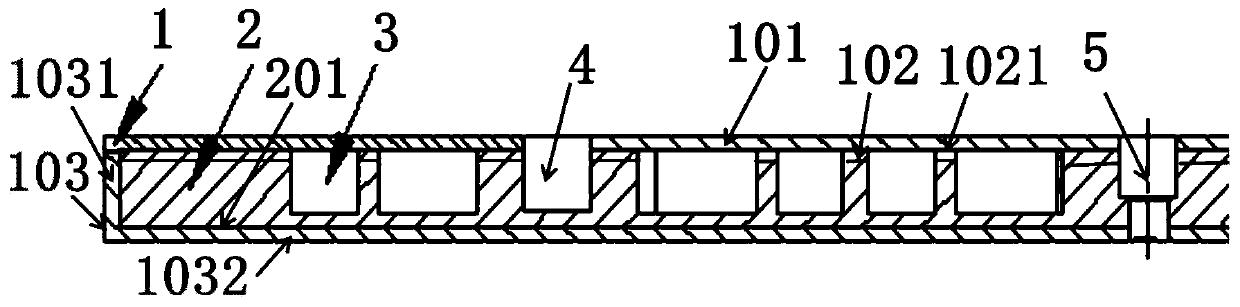

[0125] This embodiment provides a composite cooling water tray, such as figure 2 As shown, the cooling water tray includes an aluminum shell 1 and a copper layer 2 wrapped in the aluminum shell 1;

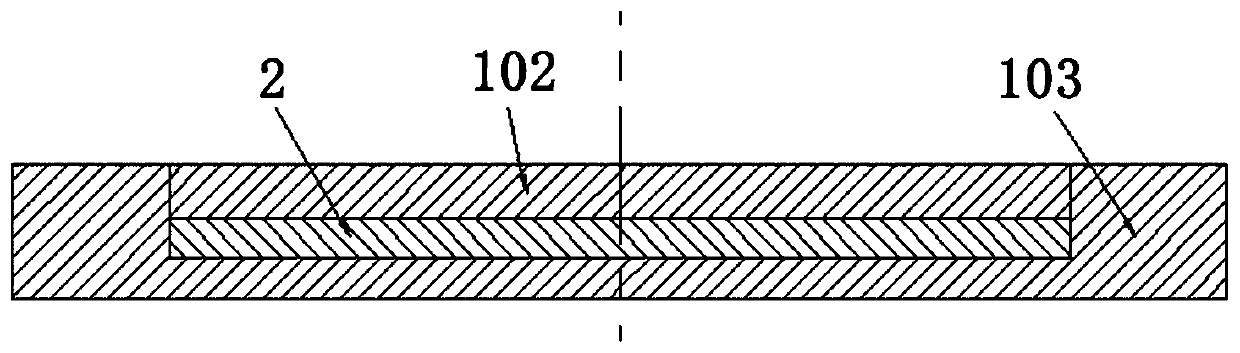

[0126] The aluminum shell includes an aluminum upper layer 101, an aluminum middle layer 102 and a grooved aluminum base 103; a copper layer 2 and the aluminum middle layer 102 are sequentially arranged on the grooved part of the grooved aluminum base 103 from bottom to top, The upper surface 1021 of the aluminum intermediate layer 102 is flush with the protruding surface 1031 of the grooved aluminum base 103, the thickness of the groove portion 1032 of the grooved aluminum base 103 is 1mm, the thickness of the aluminum upper layer 101 is 1mm, and the copper layer The thickness of 2 is 5 mm, the thickness of aluminum middle layer 102 is 1 mm, the material of aluminum upper layer 101, aluminum middle layer 102 and grooved aluminum base 103 is aluminum alloy 6061, and the material o...

Embodiment 2

[0138] This embodiment provides a composite cooling water tray, the cooling water tray includes an aluminum shell and a copper layer wrapped in the aluminum shell;

[0139] The aluminum shell includes an aluminum upper layer, an aluminum middle layer, and a grooved aluminum base; a copper layer and the aluminum middle layer are sequentially arranged in the groove of the grooved aluminum base from bottom to top, and the upper surface of the aluminum middle layer It is flush with the protruding surface of the grooved aluminum base, the thickness of the groove part of the grooved aluminum base is 1.5mm, the thickness of the upper aluminum layer is 1.5mm, the thickness of the copper layer is 4.5mm, and the thickness of the aluminum middle layer 0.5mm, the aluminum upper layer, the aluminum middle layer and the grooved aluminum base are made of aluminum alloy 6063, and the copper layer is made of TU2 oxygen-free copper;

[0140]The aluminum intermediate layer and the copper layer a...

Embodiment 3

[0151] This embodiment provides a composite cooling water tray, the cooling water tray has the same structure as that of Embodiment 1, and its manufacturing method includes the following steps:

[0152] (1) After punching a through hole on the copper layer, carry out physical vapor deposition coating on the surface of the copper layer. The film thickness is 9 μm, and the film composition is titanium with a purity of 99.95%. Aluminum pins are driven into the through holes, and the aluminum pins are The unilateral fit gap between the sub and the through hole is 0.025mm;

[0153] (2) Ultrasonic cleaning of the copper layer, grooved aluminum base and aluminum interlayer for 8 minutes, followed by vacuum drying to complete the pretreatment;

[0154] (3) A copper layer and an aluminum intermediate layer are arranged sequentially from bottom to top in the groove portion of the groove-shaped aluminum base to obtain assembled components, and the assembled components are sequentially su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com