Preparation method of nano magnetic particles

A nano-magnetic particle and magnetic particle technology, which is applied in the preparation of microspheres and microcapsule preparations, can solve the problems of uneven size, large surface area, and small particle size of magnetic microspheres, and achieve easy control of the size and preparation Simple method and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

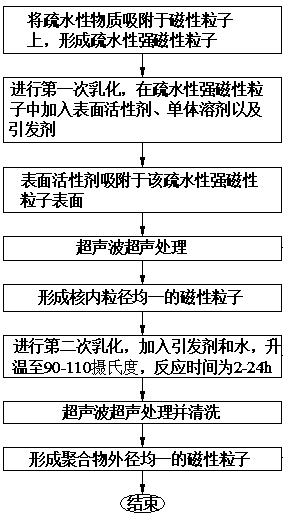

[0024] see figure 1 , is a process flow diagram of the present invention, as shown in the figure, the method comprises the following steps:

[0025] Step 1: Adsorbing hydrophobic substances on magnetic particles to form hydrophobic strong magnetic particles;

[0026] Step 2: Carry out the first emulsification, add surfactant, monomer solvent and initiator to the hydrophobic strong magnetic particles;

[0027] Step 3: The surfactant is adsorbed on the surface of the hydrophobic strong magnetic particle;

[0028] Step 4: Ultrasonic ultrasonic treatment;

[0029] Step 5: forming magnetic particles with uniform particle size in the core;

[0030] Step 6: Carry out the second emulsification, add initiator and water, and raise the temperature to 90-110 。 C, the reaction time is 2-24h;

[0031] Step 7: Ultrasonic ultrasonic treatment and cleaning;

[0032] Step 8: forming magnetic particles with a uniform outer diameter of the polymer.

[0033] In this embodiment, the magnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com