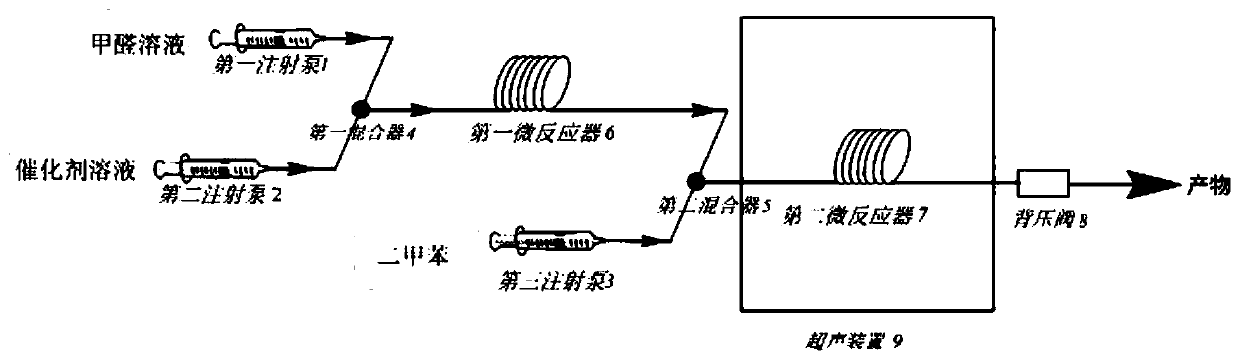

Micro-reaction device and method for preparing xylene formaldehyde resin by using micro-reaction device

A technology of xylene formaldehyde resin and micro-reaction device, applied in chemical instruments and methods, chemical/physical/physical chemical reactors, chemical/physical/physical chemical processes, etc. Performance can not meet the requirements, mass transfer and heat transfer efficiency limitations, etc., to achieve the effect of reducing the influence of equipment and operators, increasing the utilization rate of sulfuric acid, and shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

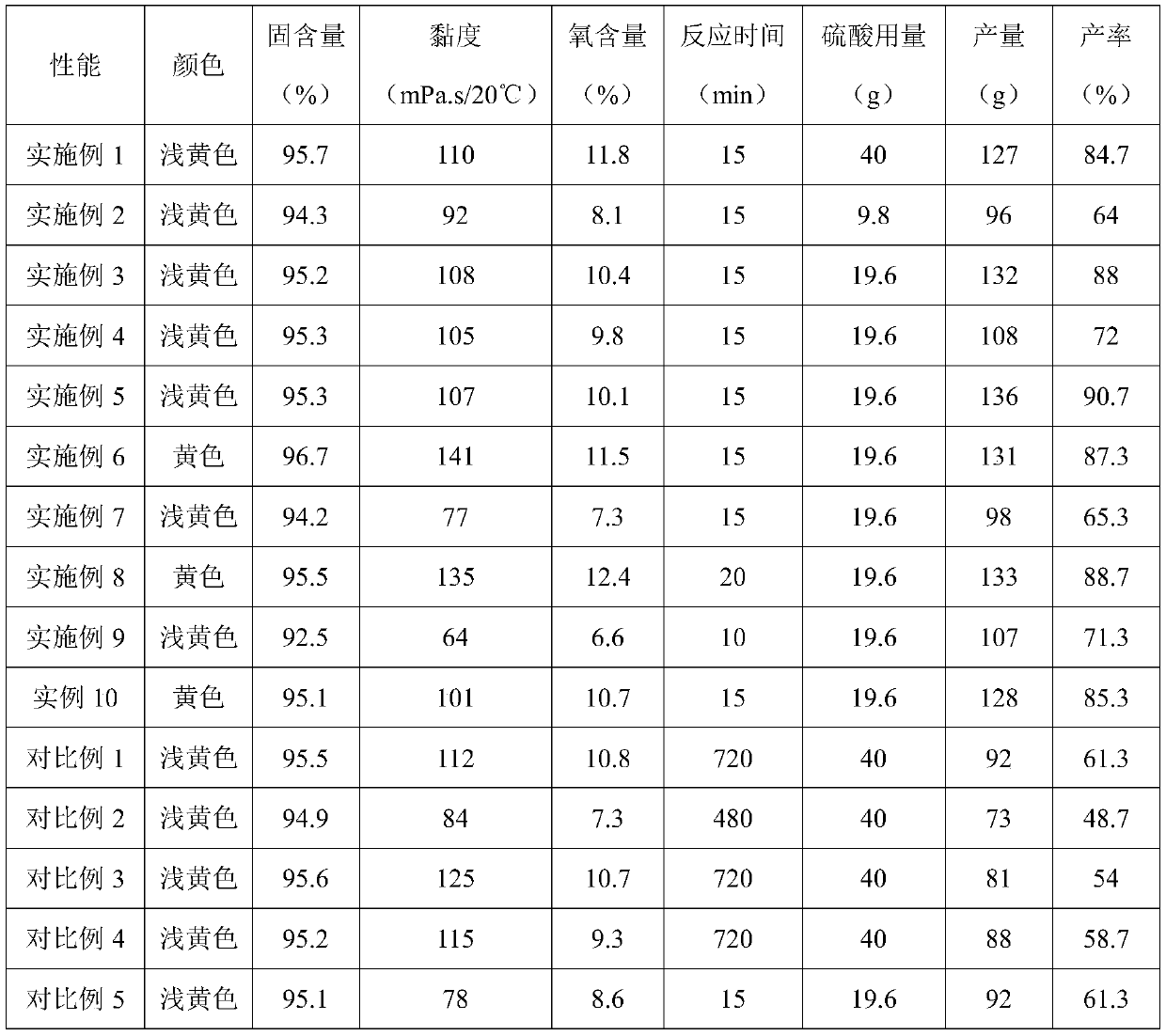

Examples

Embodiment 1

[0029] The formaldehyde solution (the concentration of the formaldehyde solution is 37wt%) is flushed into the syringe pump as one phase, and the catalyst sulfuric acid (the concentration of sulfuric acid is 92.5wt%) is flushed into the syringe pump as the other phase, and the two phases are simultaneously injected into the first microreactor , heated at 80°C, wherein the molar ratio of formaldehyde to catalyst sulfuric acid is 1:0.15, and the two-phase flow rates are 0.316ml / min and 0.035ml / min respectively; the reaction mixture of formaldehyde and catalyst, and xylene as the other phase The mixture passes through the second microreactor equipped with a backpressure valve at the end, the rated pressure set by the backpressure valve is 15bar, the flow rate of xylene is 0.617ml / min, the second microreactor is placed in an ultrasonic device for ultrasonication, and simultaneously Heat treatment and react at 105°C for 15 minutes, wherein the molar ratio of formaldehyde to xylene i...

Embodiment 2

[0031]The formaldehyde solution (the concentration of the formaldehyde solution is 37wt%) is flushed into the syringe pump as one phase, and the catalyst sulfuric acid (the concentration of sulfuric acid is 90wt%) is flushed into the syringe pump as the other phase, and the two phases are simultaneously injected into the first microreactor, Heating at 80°C, wherein the molar ratio of formaldehyde to catalyst sulfuric acid is 1:0.1, and the two-phase flow rates are 0.318ml / min and 0.024ml / min respectively; the reaction mixture of formaldehyde and catalyst is mixed with xylene as the other phase Through the second microreactor with a backpressure valve at the end, the rated pressure set by the backpressure valve is 13bar, and the xylene flow rate is 0.658ml / min. The second microreactor is placed in an ultrasonic device for ultrasonication and heating Treatment, react at 110°C for 10 minutes, wherein the molar ratio of formaldehyde to xylene is 1:1.27, and the molar ratio of xylen...

Embodiment 3

[0033] The formaldehyde solution (the concentration of the formaldehyde solution is 37wt%) is flushed into the syringe pump as one phase, and the catalyst sulfuric acid (the concentration of sulfuric acid is 95wt%) is flushed into the syringe pump as the other phase, and the two phases are simultaneously injected into the first microreactor, Heating at 80°C, wherein the molar ratio of formaldehyde to catalyst sulfuric acid is 1:0.2, and the two-phase flow rates are 0.312ml / min and 0.045ml / min respectively; the reaction mixture of formaldehyde and catalyst is mixed with xylene as the other phase Through the second microreactor with a back pressure valve at the end, the rated pressure set by the back pressure valve is 10bar, the flow rate of xylene is 0.643ml / min, the second microreactor is placed in an ultrasonic device for ultrasonication and heating Treatment, react at 120°C for 15 minutes, wherein the molar ratio of formaldehyde to xylene is 1:1.27, and the molar ratio of xyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com