Vanadium disulfide@carbon paper nanomaterial, preparation method thereof and magnesium-lithium double-ion battery

A technology of vanadium disulfide and nanomaterials, applied in secondary batteries, chemical instruments and methods, nanotechnology, etc., can solve the problems of poor battery capacity and rate performance, reduce ion migration paths, simplify processes, and improve The effect of battery capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a vanadium disulfide@carbon paper nanomaterial (E-VS 2 @C) preparation method, comprises the following steps:

[0030] N-octylamine, NH 4 VO 3 Mix with thioacetamide to obtain a mixed solution;

[0031] Solvothermal reaction is carried out between the mixed solution and carbon paper to obtain the vanadium disulfide@carbon paper nanomaterial.

[0032] In the present invention, the n-octylamine, NH 4 VO 3 The usage ratio of thioacetamide and thioacetamide is preferably 12-15mL: 0.081-0.082g: 0.262-0.263g. The present invention utilizes n-octylamine to carry out layer expansion modification on vanadium disulfide, so that the interlayer of vanadium disulfide is expanded, and its morphology and structure are also optimized and more open, which is conducive to shortening the ion migration path and facilitating ion intercalation and deintercalation, thereby The battery capacity and rate performance are greatly improved.

[0033] In the present inv...

Embodiment 1

[0045] Step 1: Sample Preparation

[0046] Solvothermal Synthesis of E-VS 2 @C: Measure 12mL n-octylamine in 35mL Teflon liner. Weigh 0.081g of NH 4 VO 3 and 0.262g of thioacetamide were sequentially added to the above-mentioned polytetrafluoroethylene lining filled with n-octylamine, and after stirring for 1h, a piece of carbon paper with a diameter of 16mm was added thereto. Then seal the polytetrafluoroethylene liner in a high-pressure reactor, and react at 160°C for 20h. At the end of the reaction, take out the carbon paper and wash it alternately with deionized water and ethanol for 4 times, and dry it under vacuum at 60°C for 10 hours to obtain E-VS 2 @C, VS 2 The loading range on the carbon paper is 1.2-2.4 mg, and the mass percentage of octylamine embedding is 16±0.5%.

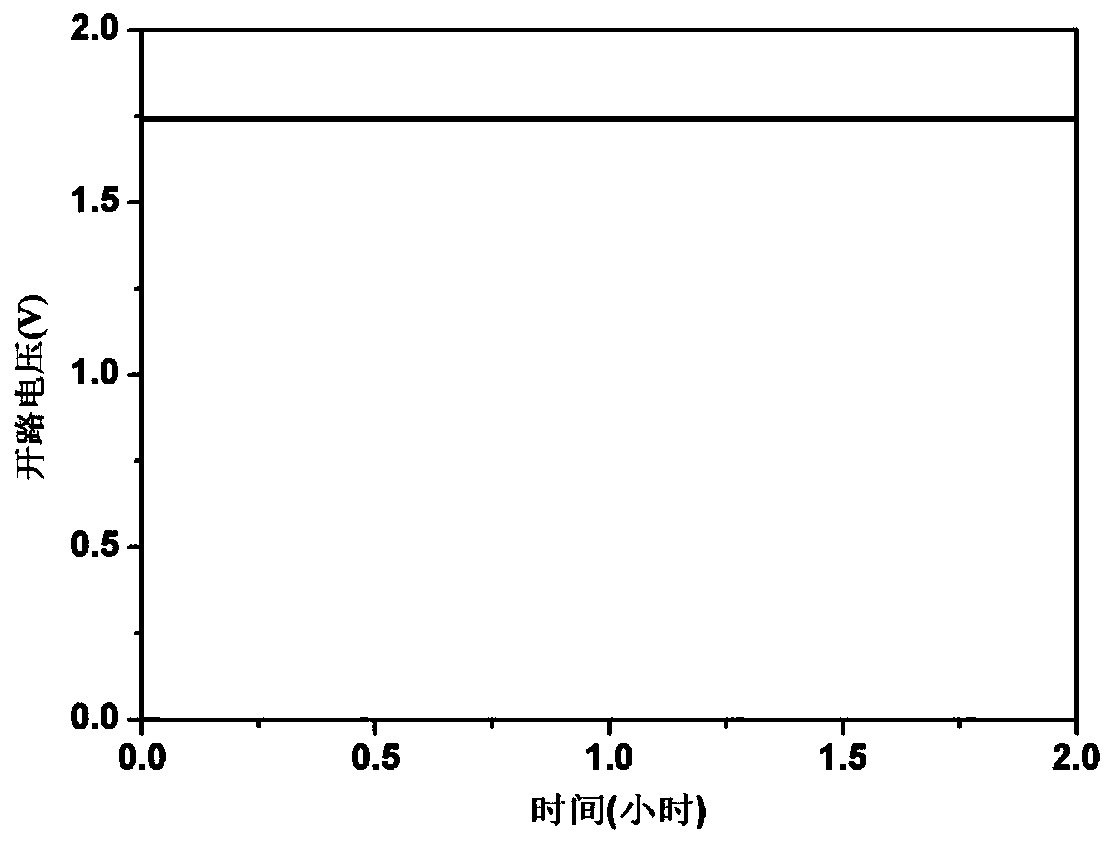

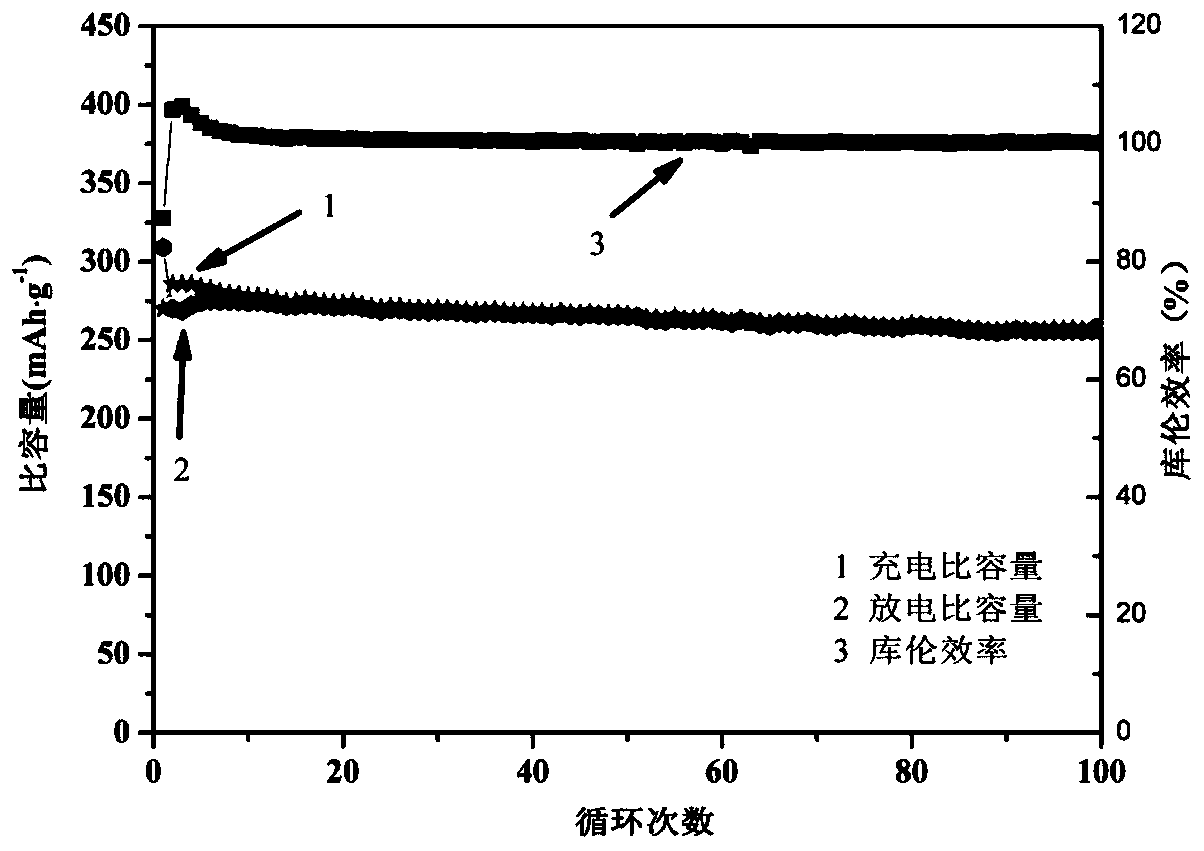

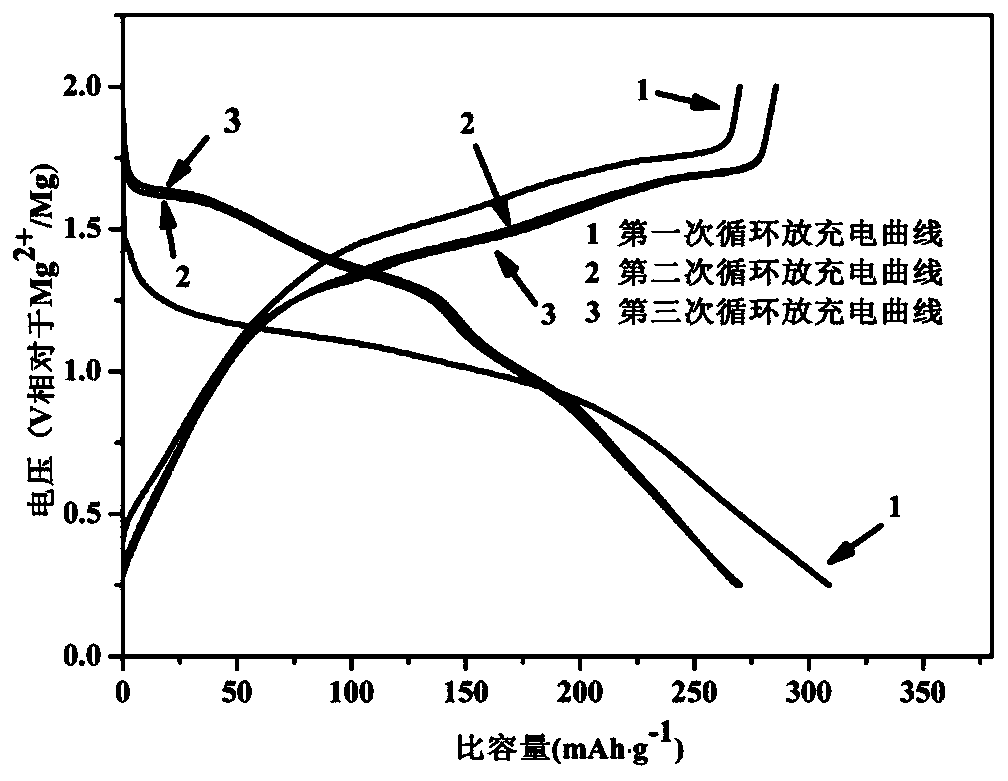

[0047] Step 2: Battery System

[0048] Preparation of positive electrode sheet

[0049] E-VS 2 @C is directly used as the positive electrode of the battery, and the mass density of the active ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com