Polyether ester type thermoplastic polyurethane elastomer foamed beads and preparation method thereof

A technology of thermoplastic polyurethane and foamed beads, which is applied in the field of polyether ester thermoplastic polyurethane elastomer foamed beads and its preparation, can solve the problems of poor strength, high cost, non-wear resistance, etc., and achieve the expansion of application range, The effect of high tensile strength and overcoming high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

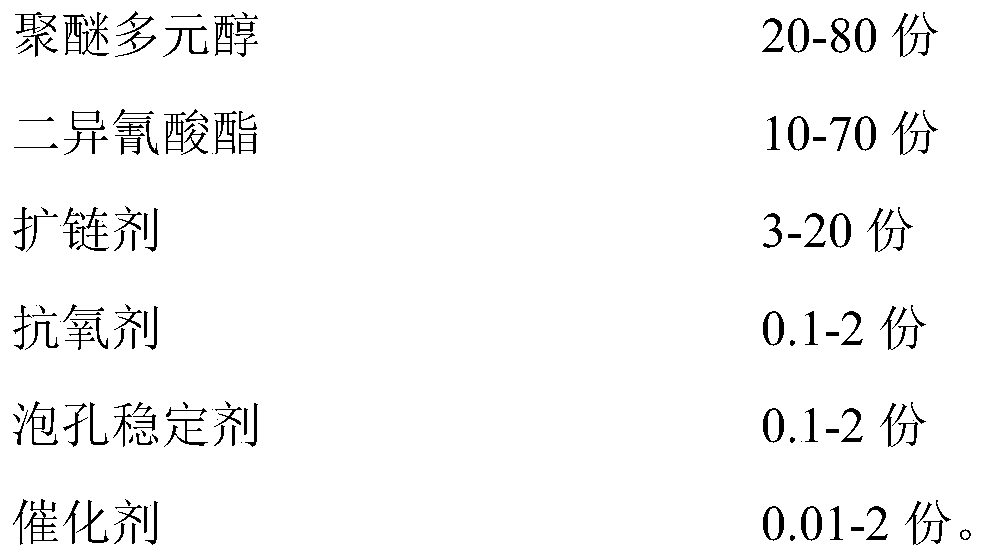

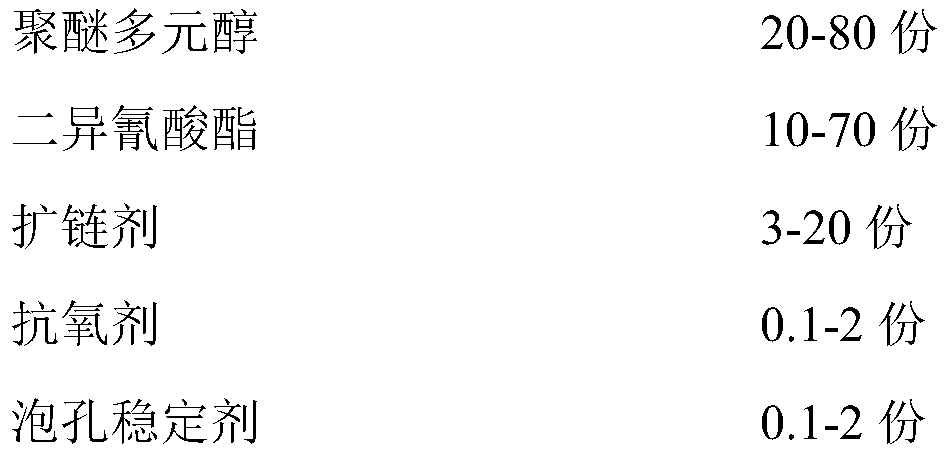

Method used

Image

Examples

Embodiment 1

[0028] 1. 50 parts by mass of polyether ester polyol (PEM-molecular weight 1000), 30 parts by mass of MDI, 10 parts by mass of 1,4-butanediol, 1 part by mass of antioxidant 126, 0.5 parts by mass of cell regulator poly Tetrafluoroethylene and 0.1 parts of the catalyst bismuth octadecanoate are accurately measured and injected into the twin-screw extruder through the pouring machine, and the temperature of the screw temperature zone is well controlled so that the TPU polymer melt and the small molecule additives are evenly mixed to obtain a homogeneous system After the melt passes through the die, it is pelletized underwater, dehydrated by a vibrating screen and dried to obtain transparent particles. Among them, the die temperature of the twin-screw extruder is 190°C, the melt pump pressure is 5MPa, the water temperature is 30°C, and the speed of the pelletizer is 3000r / min;

[0029] 2. Add the particles prepared above into the supercritical autoclave after accurate measurement...

Embodiment 2

[0031] 1. 50 parts by mass of polyether ester polyol (PEM-molecular weight 1000), 30 parts by mass of MDI, 10 parts by mass of 1,4-butanediol, 1 part by mass of antioxidant 126, 0.5 parts by mass of cell regulator poly Tetrafluoroethylene and 0.1 parts of the catalyst bismuth octadecanoate are accurately measured and injected into the twin-screw extruder through the pouring machine, and the temperature of the screw temperature zone is well controlled so that the TPU polymer melt and the small molecule additives are evenly mixed to obtain a homogeneous system After the melt passes through the die, it is pelletized underwater, dehydrated by a vibrating screen and dried to obtain transparent particles. Among them, the die temperature of the twin-screw extruder is 190°C, the melt pump pressure is 5MPa, the water temperature is 30°C, and the speed of the pelletizer is 3000r / min;

[0032] 2. Add the above-mentioned particles to the supercritical autoclave after accurate measurement,...

Embodiment 3

[0034] 1. 50 parts by mass of polyether ester polyol (PEM-molecular weight 1000), 30 parts by mass of MDI, 10 parts by mass of 1,4-butanediol, 1 part by mass of antioxidant 126, 0.5 parts by mass of cell regulator poly Tetrafluoroethylene and 0.1 parts of the catalyst bismuth octadecanoate are accurately measured and injected into the twin-screw extruder through the pouring machine, and the temperature of the screw temperature zone is well controlled so that the TPU polymer melt and the small molecule additives are evenly mixed to obtain a homogeneous system After the melt passes through the die, it is pelletized underwater, dehydrated by a vibrating screen and dried to obtain transparent particles. Among them, the die temperature of the twin-screw extruder is 190°C, the melt pump pressure is 5Mpa, the water temperature is 30°C, and the speed of the pelletizer is 3000r / min;

[0035] 2. Add the above-mentioned particles to the supercritical autoclave after accurate measurement,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com