A kind of high-efficiency drag reducer and its application method

A drag reducer, high-efficiency technology, applied in mechanical equipment, pipeline systems, gas/liquid distribution and storage, etc., can solve the problems of molecular chain fracture shear degradation, drag reducer loss of application performance, etc., to reduce turbulent flow resistance, Promote shear resistance and increase pipeline throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

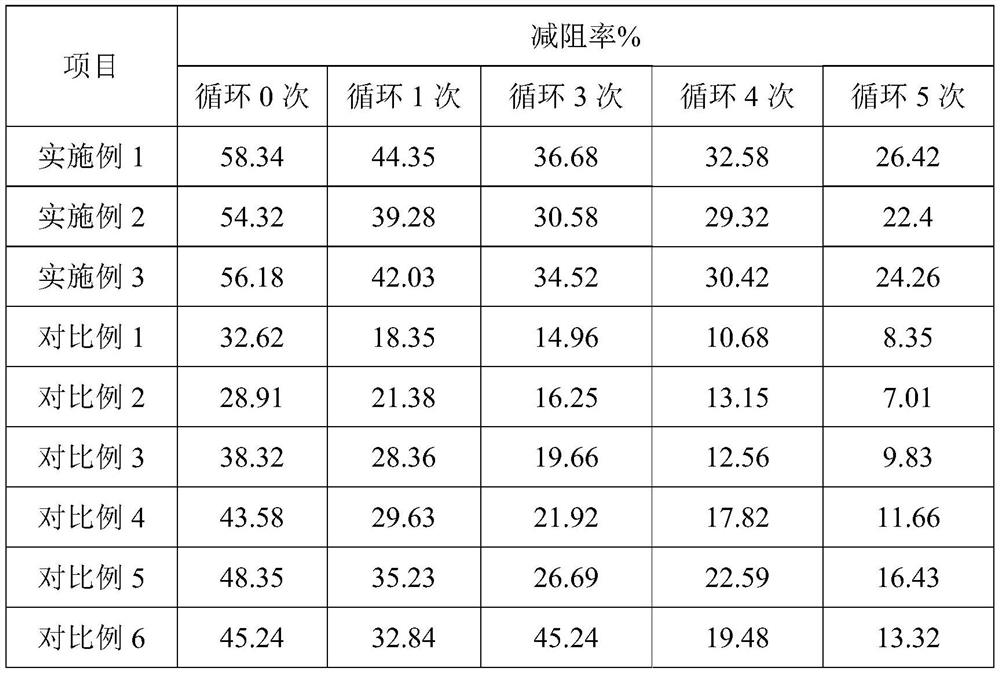

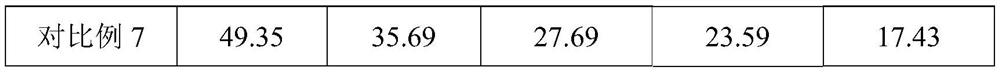

Examples

preparation example Construction

[0049] In one embodiment, the preparation method of the modified wood flour includes the following steps: sequentially undergoing plasma treatment and silane coupling agent treatment to prepare the modified wood flour.

[0050] In a preferred embodiment, the preparation method of the modified wood powder comprises the following steps: first dissolving the wood powder in an ethanol solution containing 4wt% silane coupling agent after plasma treatment, at 20- Stand at 30°C for 10-20min, then evaporate ethanol at 80-90°C, and dry for 12-24h.

[0051] The wood flour is a natural organic wood polymer material, which has the characteristics of renewable, low carbon, energy saving, and environmental protection. Due to its rigidity and flexibility, it has the characteristics of some rubber materials. Its surface is rich in hydroxyl groups, making it somewhat hydrophilic.

[0052] In a preferred embodiment, the mass ratio of the wood flour to the silane coupling agent is 1:0.12.

[...

Embodiment 1

[0076] Example 1 provides a high-efficiency drag reducer, including A component and B component; the preparation raw material of the A component includes polyquaternium-11; the B component is an α-olefin copolymer; the The raw materials for the preparation of component B include long-chain alkyl methacrylate, acrylic acid, initiator, emulsifier, modified wood flour, and compatibilizer; the mass ratio of component A to component B is 1:1 .

[0077] The CAS number of the polyquaternium-11 is 53633-54-8.

[0078] The weight ratio of the long-chain alkyl methacrylate, acrylic acid, initiator, emulsifier, modified wood flour and compatibilizer is 30:1:0.3:4:6.9:1.35.

[0079] The long-chain alkyl methacrylate is octadecyl methacrylate.

[0080] The acrylic acid is 2,3-dihydroxypropyl acrylic acid.

[0081] The initiator is a mixture of potassium persulfate and sodium sulfite.

[0082] The molar ratio of potassium persulfate to sodium sulfite is 2:3.

[0083] The emulsifier is ...

Embodiment 2

[0097] Example 2 is basically the same as Example 1, the only difference is: a high-efficiency drag reducer, including A component and B component; the preparation raw materials of the A component include polyquaternium-11; the B group Divided into α-olefin copolymer; the preparation raw materials of the B component include long-chain alkyl methacrylate, acrylic acid, initiator, emulsifier, modified wood powder, compatibilizer; the A component and B The mass ratio of the components is 1:0.8.

[0098] The weight ratio of the long-chain alkyl methacrylate, acrylic acid, initiator, emulsifier, modified wood flour and compatibilizer is 25:1:0.2:2:5.75:1.13.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com