Sulfur composite material for lithium-sulfur battery and preparation method of sulfur composite material

A technology of composite materials and lithium-sulfur batteries, applied in the field of electrochemistry, to achieve the effects of improved stability, good adsorption, and good high-current discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

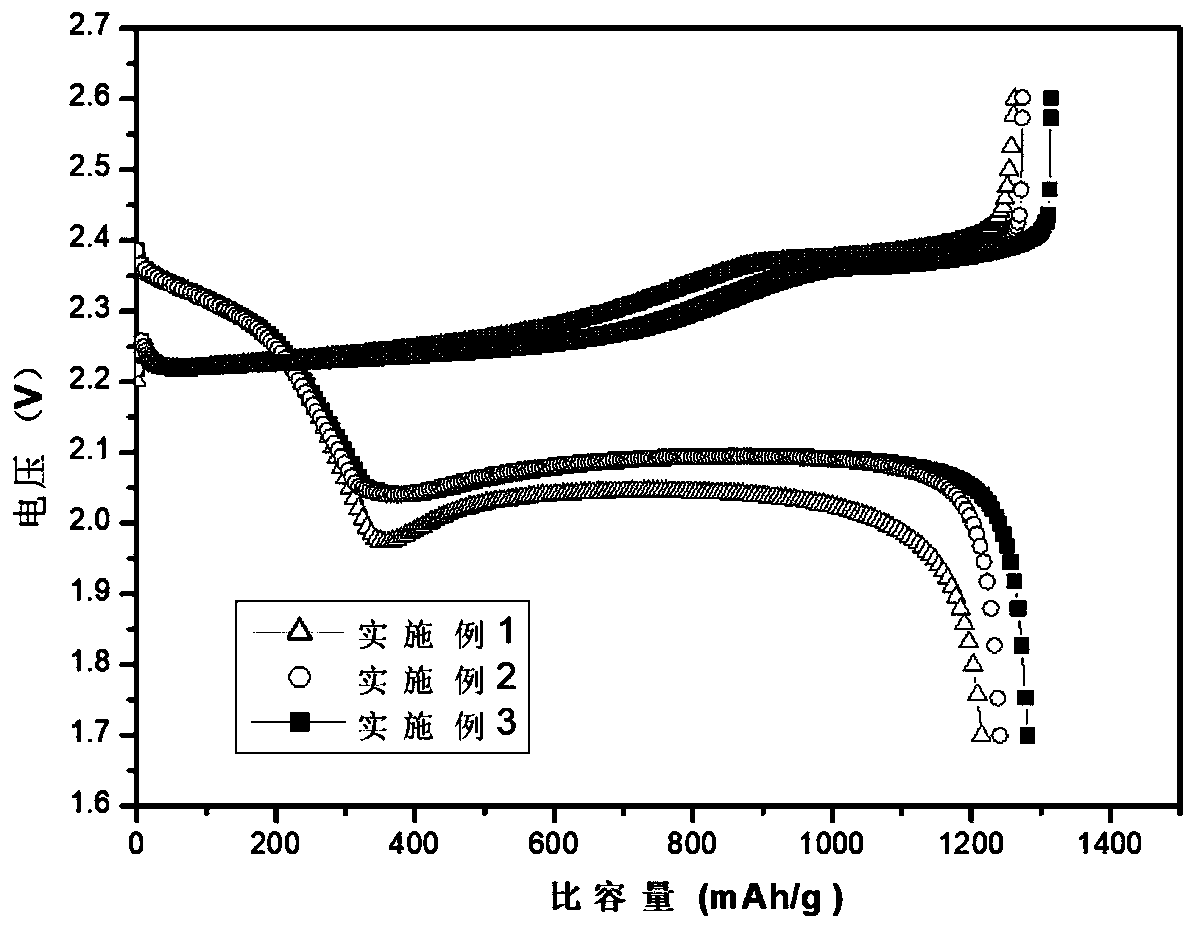

Embodiment 1

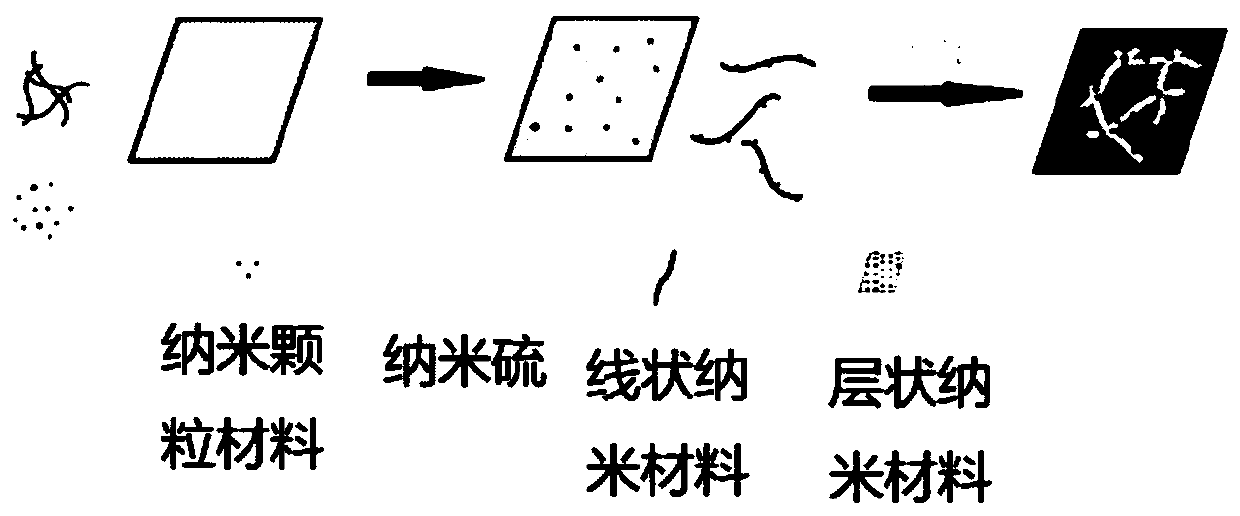

[0031] This embodiment provides a method for preparing sulfur composite materials, such as figure 1 Shown is the schematic diagram of the preparation of the sulfur composite material in this embodiment, the steps are as follows:

[0032] 1) Add 5 g of polyvinylpyrrolidone to 100 mL of deionized water, and stir at 50° C. for 2 h to prepare a uniform solution. 2g of nano-sulfur (20nm) was added to the above solution, dispersed by ultrasonic at 50°C for 2h, and then stirred for 12h.

[0033] 2) Add 0.2g graphene to 50mL ethanol, ultrasonically disperse for 2h; add 0.2g carbon nanotubes to 50mL ethanol, ultrasonically disperse for 2h; add 0.1g titanium dioxide (20nm) to 50mL ethanol, ultrasonically disperse for 2h. Under stirring, the titanium dioxide dispersion was added to the carbon nanotube dispersion, and stirred at 30° C. for 5 h; then the graphene dispersion was added to the above mixture, and the stirring was continued for 12 h to prepare a nanomaterial dispersion.

[00...

Embodiment 2

[0038] This embodiment provides a method for preparing a sulfur composite material, the steps of which are as follows:

[0039] 1) Add 3 g of polyvinylpyrrolidone to 100 mL of deionized water, and stir at 50° C. for 2 h to prepare a uniform solution. Add 12g of sodium thiosulfate to the above solution, then slowly add 100mL of 2M formic acid solution dropwise under stirring, and then stir for 10h. Preparation of nano-sulfur dispersion.

[0040] 2) Add 0.2g graphene to 50mL deionized water, ultrasonically disperse for 2h; add 0.2g carbon nanotubes to 50mL deionized water, ultrasonically disperse for 2h; add 0.1g titanium nitride (20nm) to 50mL deionized water, Ultrasonic dispersion 2h. Under stirring, the titanium nitride dispersion was added to the carbon nanotube dispersion, and stirred at 30°C for 5 hours; then the graphene dispersion was added to the above mixture, and continued to stir for 12 hours to prepare the nanomaterial dispersion liquid.

[0041] 3) Slowly add t...

Embodiment 3

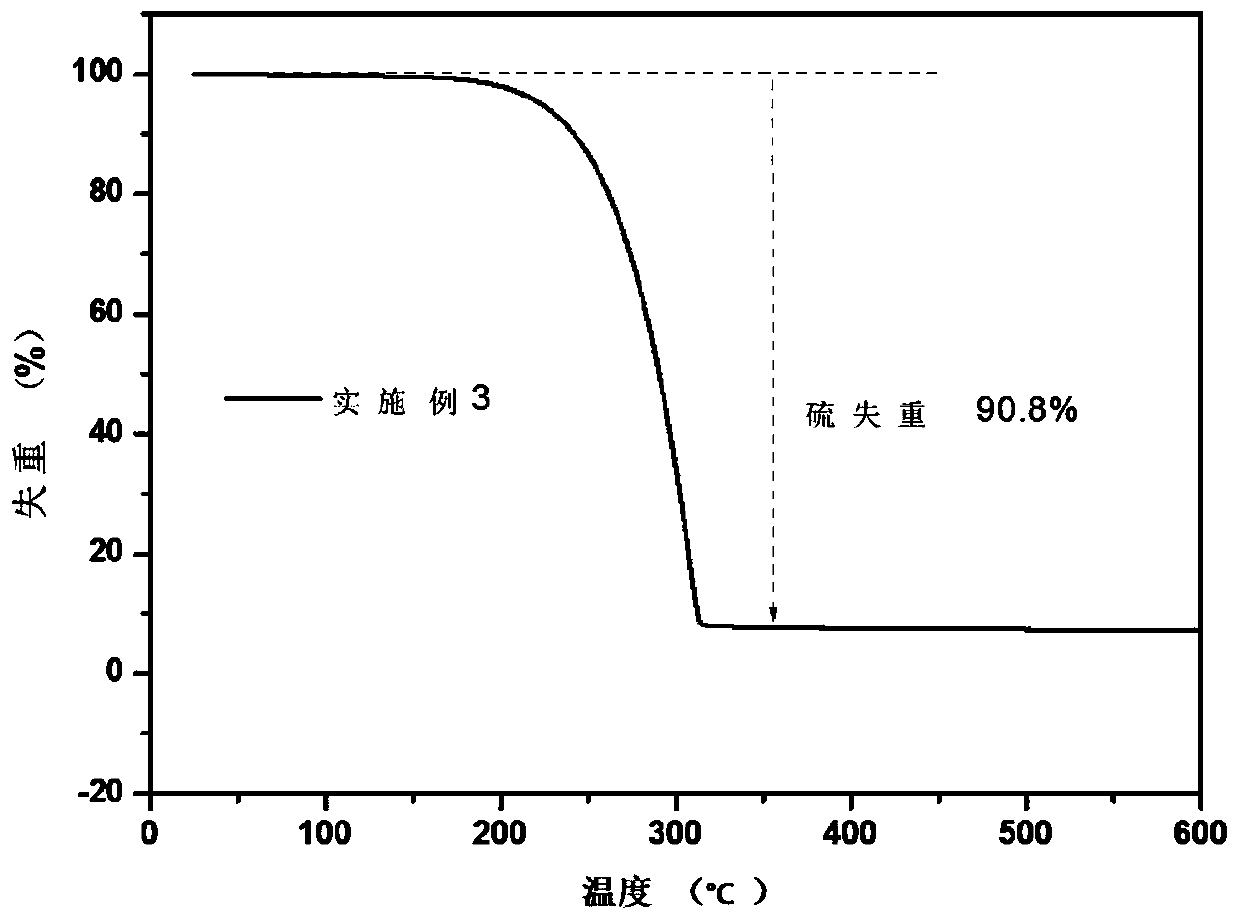

[0045] This embodiment provides a method for preparing a sulfur composite material, the steps of which are as follows:

[0046] 1) Add 3 g of polyvinylpyrrolidone to 100 mL of deionized water, and stir at 50° C. for 2 h to prepare a uniform solution. Add 15g of sodium thiosulfate to the above solution, then slowly add 120mL of 2M formic acid solution dropwise under stirring, and then stir for 10h. Preparation of nano-sulfur dispersion.

[0047] 2) Add 0.15g graphene to 100mL deionized water, ultrasonically disperse for 2h; add 0.15g carbon nanotubes to 100mL deionized water, ultrasonically disperse for 2h; add 0.3g titanium nitride (20nm) to 100mL deionized water, Ultrasonic dispersion 2h. Under stirring, the titanium nitride dispersion was added to the carbon nanotube dispersion, and stirred at 30°C for 5 hours; then the graphene dispersion was added to the above mixture, and continued to stir for 12 hours to prepare the nanomaterial dispersion liquid.

[0048] 3) Under u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com