A kind of purification method of quantum dot

A purification method and quantum dot technology, applied in the field of quantum dots, can solve the problems that agarose gel electrophoresis cannot be achieved, chloroform is separated, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

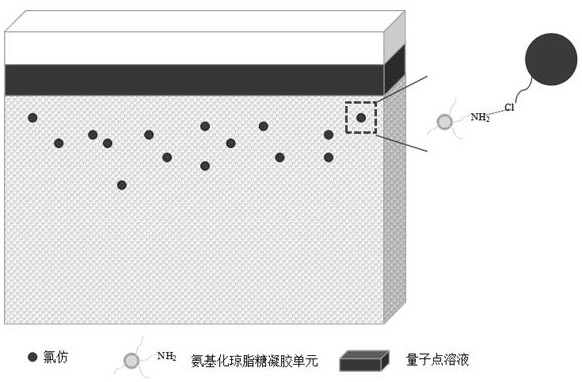

Method used

Image

Examples

Embodiment 1

[0036] Purification method according to the present embodiment is a quantum dot, comprising the steps of:

[0037] 0.3 g agarose is weighed, placed in a flask, was added 30 ml 1 * Tris- borate (TBE) buffer solution and placed in the flask, the flask into a microwave oven and heated to dissolve the agarose. Was added 0.5 ml of concentrated aqueous ammonia, stirred for 1 hour to fully dissolve and uniformly mixed, cooled to 65 o About C, Serve 1% agarose gel solution amination.

[0038]Plexiglass groove taken, washed, dried; plexiglass was placed on a horizontal slot within the die, the baffle well, put the comb. Draw a small amount of amide sealing film edges agarose solution, and allowing to set the remaining solution was poured into warm agarose film of the glue slowly expanded, until a homogeneous paste layer over the entire surface of the plexiglass plate gel plate thickness 4mm. Allowed to stand at room temperature for about 30 min, to be solidified completely, plated plastic ...

Embodiment 2

[0041] Purification method according to the present embodiment is a quantum dot, comprising the steps of:

[0042] 0.9 g agarose is weighed, placed in a flask, was added 30 ml 1 * Tris- borate (TBE) buffer solution and placed in the flask, the flask into a microwave oven and heated to dissolve the agarose. Add 10 ml 1 mmol / l thiourea solution, stirred for 1 hour to fully dissolve and uniformly mixed, cooled to 65 o About C, Serve amination 3% agarose gel solution.

[0043] Plexiglass groove taken, washed, dried; plexiglass was placed on a horizontal slot within the die, the baffle well, put the comb. Draw a small amount of liquid amination agarose gel sealing film edges, allowing to set the remaining warmed amination agarose gel was poured in the film, so that the glue slowly expand until the entire plexiglass plate forming a uniform surface layer, the gel sheet thickness between 3 mm. Allowed to stand at room temperature for about 30 min, to be solidified completely, plated pla...

Embodiment 3

[0046] Purification method according to the present embodiment is a quantum dot, comprising the steps of:

[0047] He said 3 g of agarose was placed in the flask, was added 30 ml 1 * Tris- acetate (TAE) buffer solution, was placed in the flask, the flask into a microwave oven and heated to dissolve the agarose. Add 10 ml 10 mmol / l APTES solution, stirred for 1 hour to fully dissolve and uniformly mixed, cooled to 65 o About C, 10% amination Serve agarose gel solution.

[0048] Plexiglass groove taken, washed, dried; plexiglass was placed on a horizontal slot within the die, the baffle well, put the comb. Draw a small amount of liquid amination agarose gel sealing film edges, allowing to set the remaining warmed amination agarose gel was poured in the film, so that the glue slowly expand until the entire plexiglass plate forming a uniform surface layer, the gel sheet thickness between 5 mm. Allowed to stand at room temperature for about 30 min, to be solidified completely, plated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com